Coupling with retainer and without generating axial force

A technology for cages and couplings, applied in the direction of rigid shaft couplings, couplings, engine lubrication, etc., can solve problems such as inability to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing, the present invention will be further described

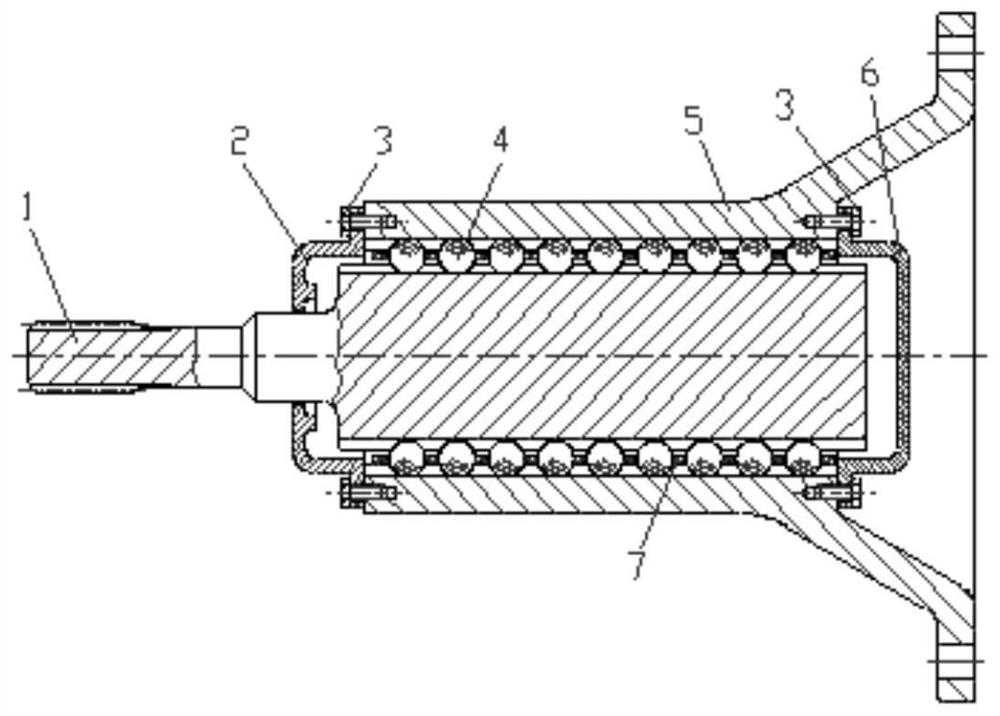

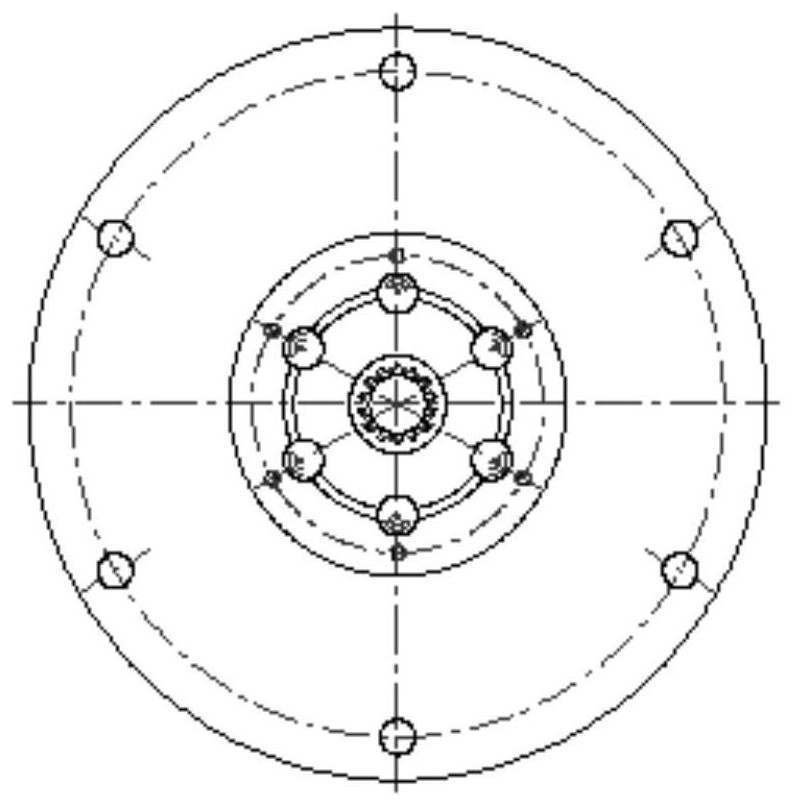

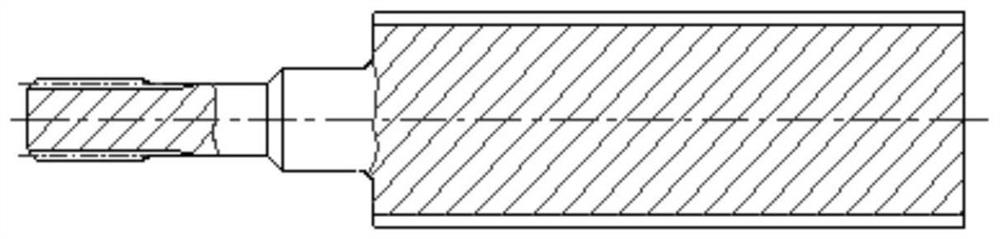

[0025] A shaft coupling with a cage that does not generate axial force according to the present invention has a structure as shown in Figure 1, which consists of an inner shaft 1, a left end cover 2, a screw 3, a steel ball 4, a transmission sleeve 5, and a right end cover 6 and cage 7 etc. are formed. Six uniformly distributed arc grooves with a diameter of ΦA are machined on the ΦC cylindrical surface of the inner shaft 1. The axis center of the arc groove ΦA is located on the cylindrical surface with a diameter of ΦB, and ΦB is greater than ΦC, so that the ΦB of the inner shaft 1 A cage 7 of graded steel balls is installed between the outer cylindrical surface and the ΦD inner cylindrical surface of the drive sleeve 5 . In the ΦD hole of the transmission sleeve 5, ΦA circular arc grooves with the same size, quantity, radial and circumferential distribution as the inner ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com