Shift control device for automatic transmission

一种自动变速器、控制装置的技术,应用在发动机控制、传动装置控制、带有齿的元件等方向,能够解决燃料消耗率恶化、行驶性恶化、驱动力不足等问题,达到抑制行驶性的恶化的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

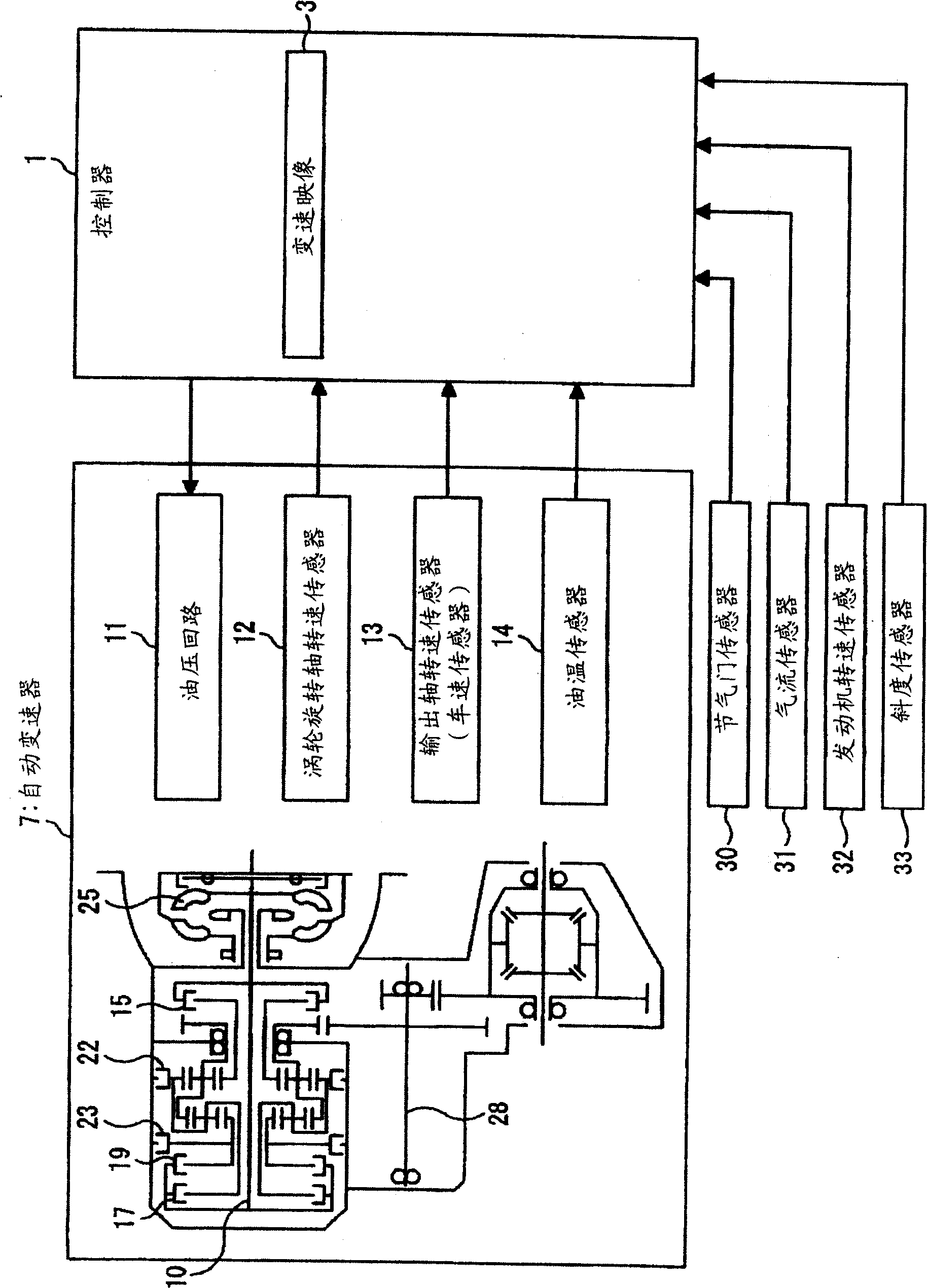

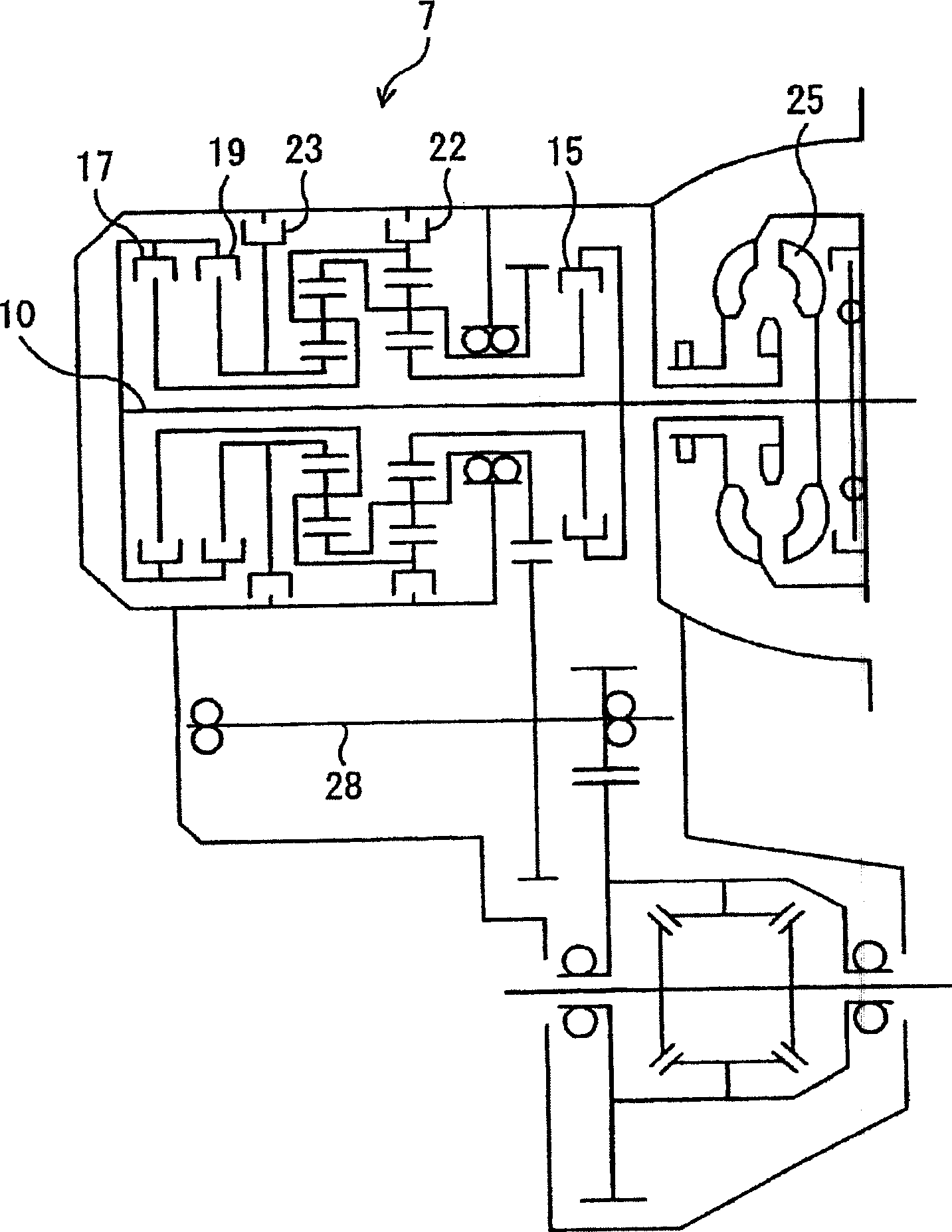

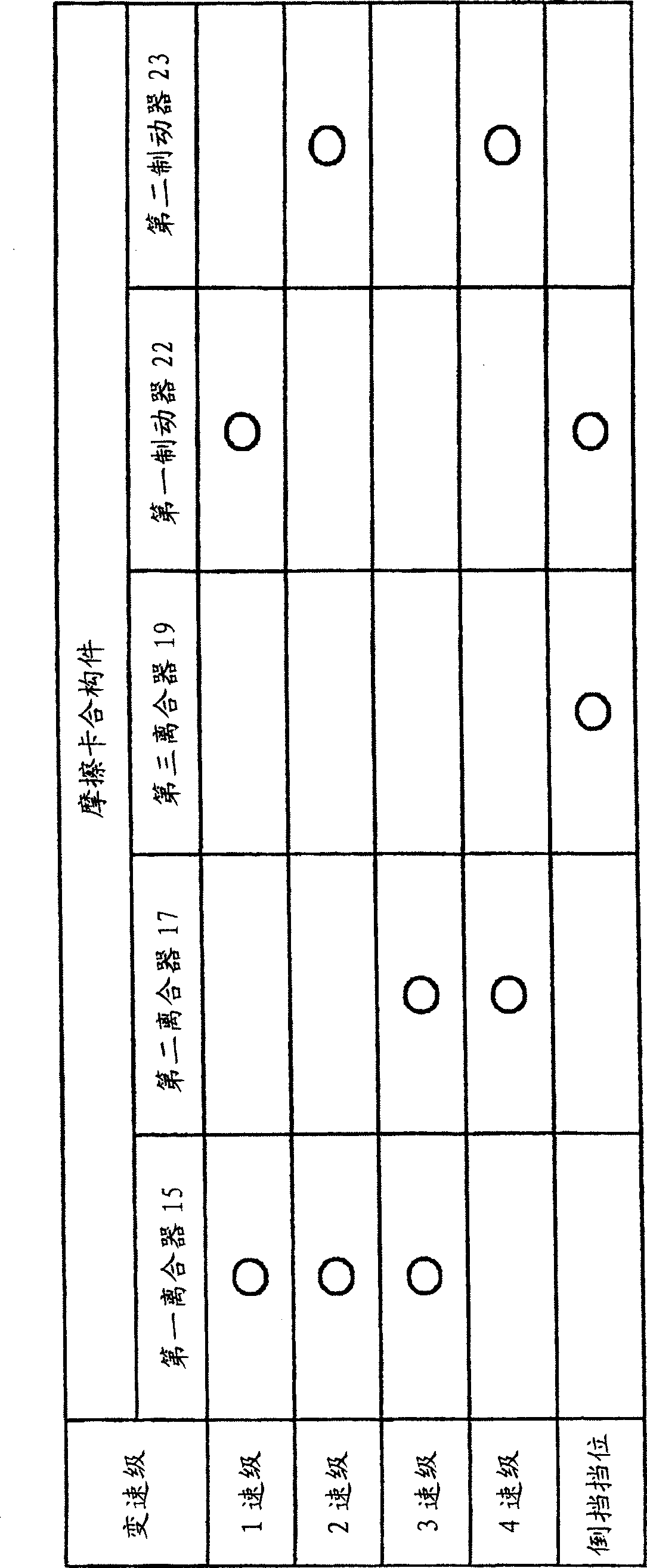

[0055] figure 1 It is a functional block diagram showing the configuration of the shift control device of the automatic transmission of the first embodiment. figure 2 It is a schematic diagram showing the structure of an automatic transmission.

[0056]The speed change control device includes: a controller 1; an input shaft speed sensor (turbine shaft speed sensor) 12 that detects the speed NT of the turbine 25 and the turbine shaft 10; and an output shaft speed sensor (vehicle speed sensor) 13 that detects the speed No of the output shaft 28 , The oil temperature sensor 14 that detects the temperature of the ATF (automatic transmission oil), the throttle sensor 30 that detects the throttle opening of the engine not shown, the airflow sensor 31 that detects the amount of intake air of the engine, and the engine speed NE that detects Various sensors such as an engine speed sensor 32, an inclination sensor 33 that detects the inclination α of the road surface the vehicle is curre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com