Wrapping-pulling woven high-strength composite material tube

A high-strength composite material, winding layer technology, applied in the direction of slender elements, building elements, etc., can solve the problems of bending, low strength, easy to be corroded at the support connection, and achieve strong integrity and good fatigue resistance. , the effect of maintaining integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

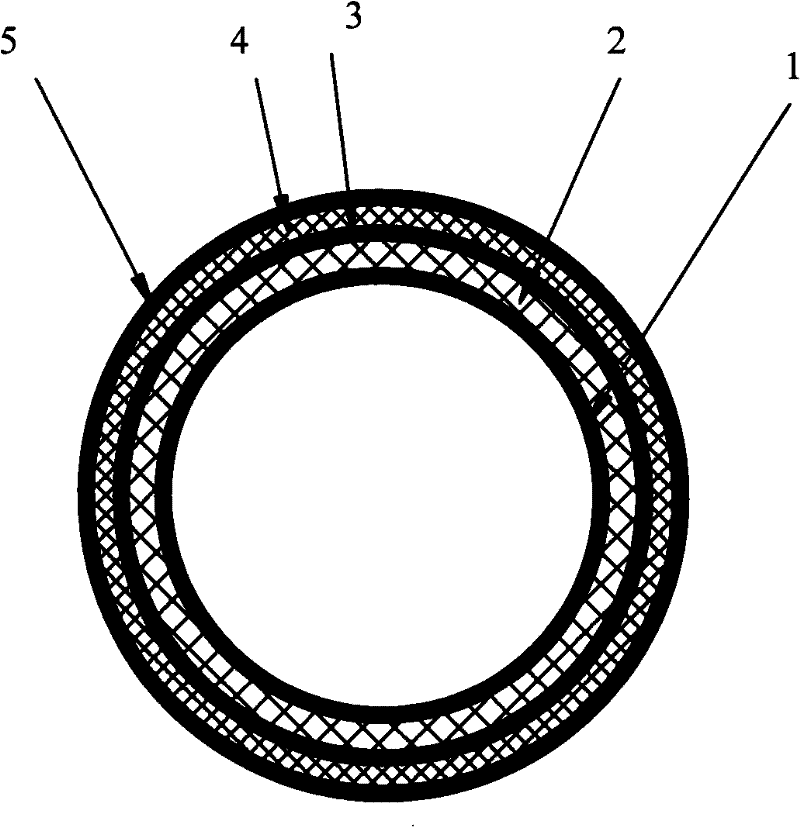

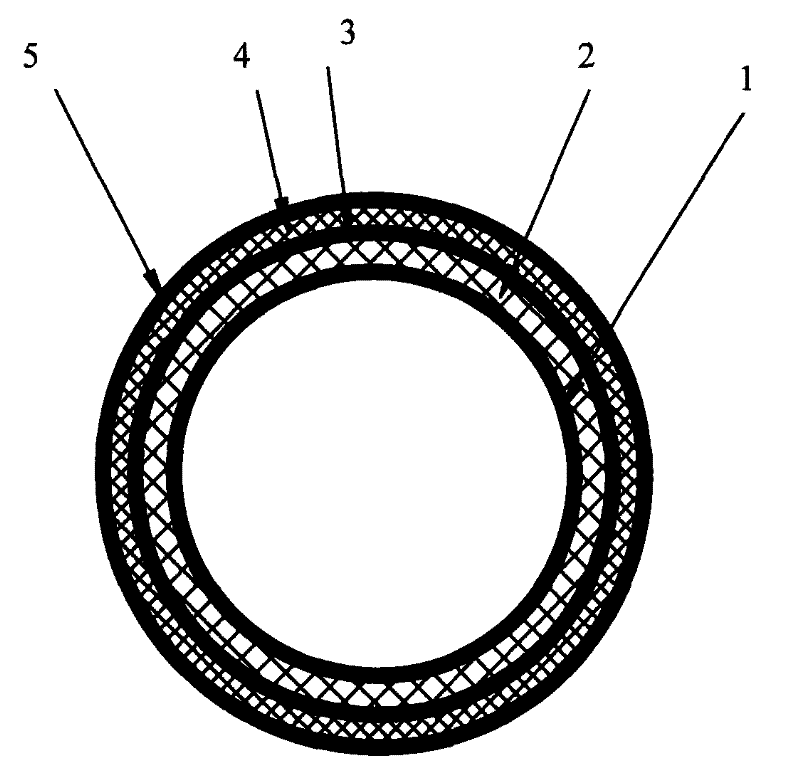

[0014] A stretch-wrapped and wound high-strength composite material pipe according to the present invention, the high-strength composite material pipe comprises a knitted chopped strand felt inner felt layer 1, a straight yarn pultrusion layer 2, and a knitted chopped strand felt intermediate felt layer 3 , High-strength yarn braided winding layer 4 and knitted chopped strand mat outer felt layer 5, straight yarn pultrusion layer 2 wrapped on the outer side of tubular knitted chopped strand felt inner felt layer 1, knitted chopped strand mat middle felt layer 3 Wrapped on the outside of the straight yarn pultrusion layer 2, the high-strength yarn braided wrapping layer 4 is wrapped on the outside of the middle felt-wrapped felt layer 3 of the knitted chopped strand mat, and the outer felt-wrapped felt layer 5 of the knitted chopped strand mat is wrapped on the outside of the high-strength yarn braided wrapping layer 4.

[0015] The felting fibers of the inner felting layer of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com