High-efficiency water curtain type spray chamber

A technology of spray booth and water curtain, which is applied to devices and coatings that apply liquid to the surface. It can solve the problems of low washing efficiency and small mixing contact surface between water and paint mist, so as to improve washing efficiency and increase capture. The effect of the ability of paint mist

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

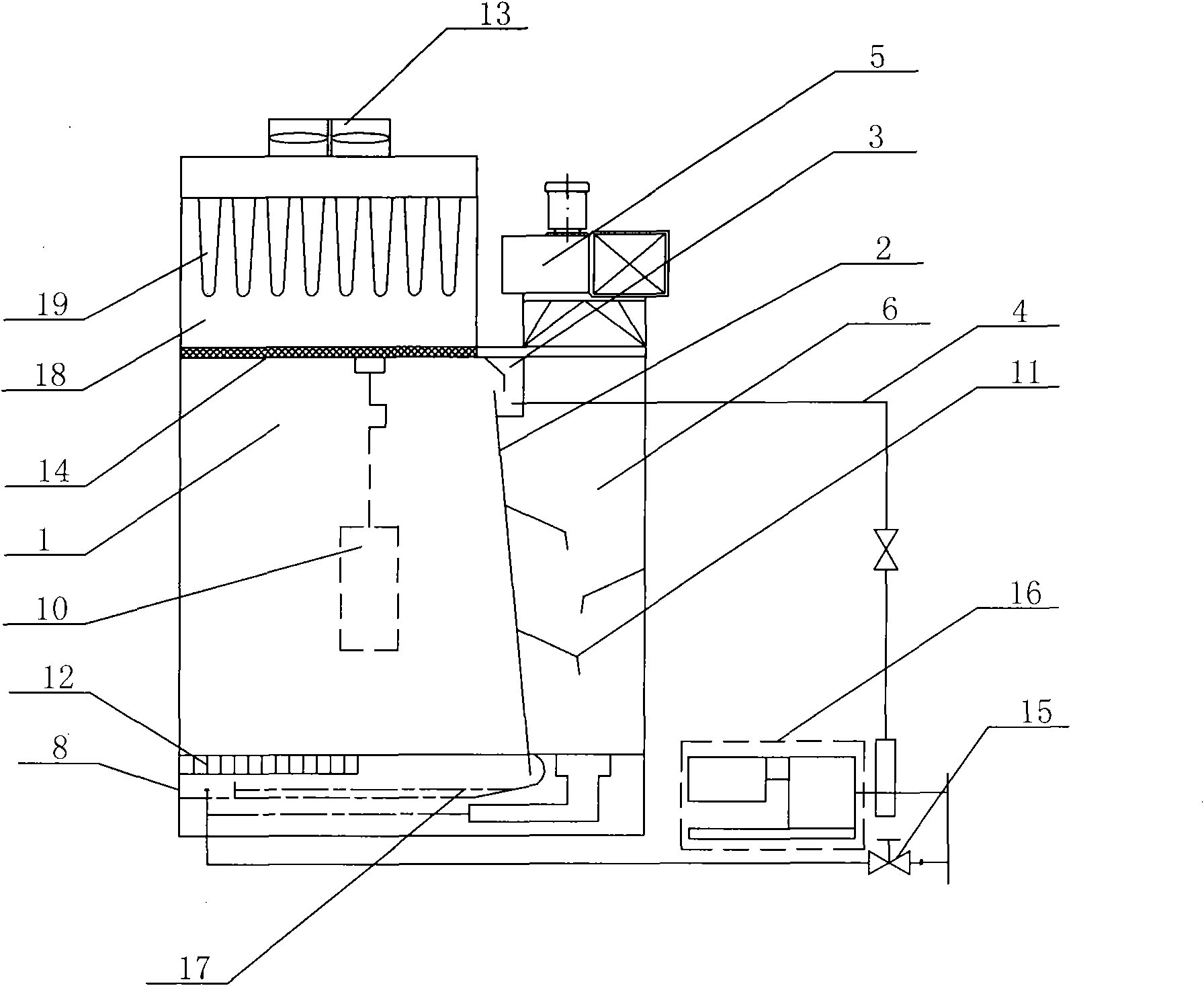

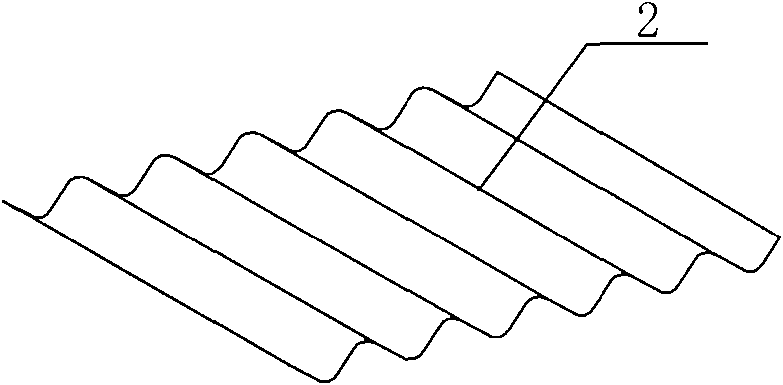

[0009] Specific implementation mode one: refer to Figure 1-6 , the specific embodiment adopts the following technical solutions: it is composed of chamber body 1, water curtain plate 2, overflow tank 3, water injection pipe 4, ventilator 5, gas-water separator 6, water pump suction port 8, workpiece 10, baffle Plate 11, grid plate 12, air outlet 13, filter screen 14, regulating valve 15, water pump 16, water storage tank 17, air supply chamber 18, filter bag 19 and sealing connection plate 20, chamber body 1 and air supply chamber 18 A filter screen 14 is provided at the joint of the air supply chamber 18, an air supply port 13 is provided at the upper end of the air supply chamber 18, several filter bags 19 are evenly arranged inside the air supply chamber 18, a water storage tank 17 is provided at the bottom of the chamber body 1, and a grid is provided above the water storage tank 17. The grille 12, the side of the water storage tank 17 is provided with a water pump suctio...

specific Embodiment approach 2

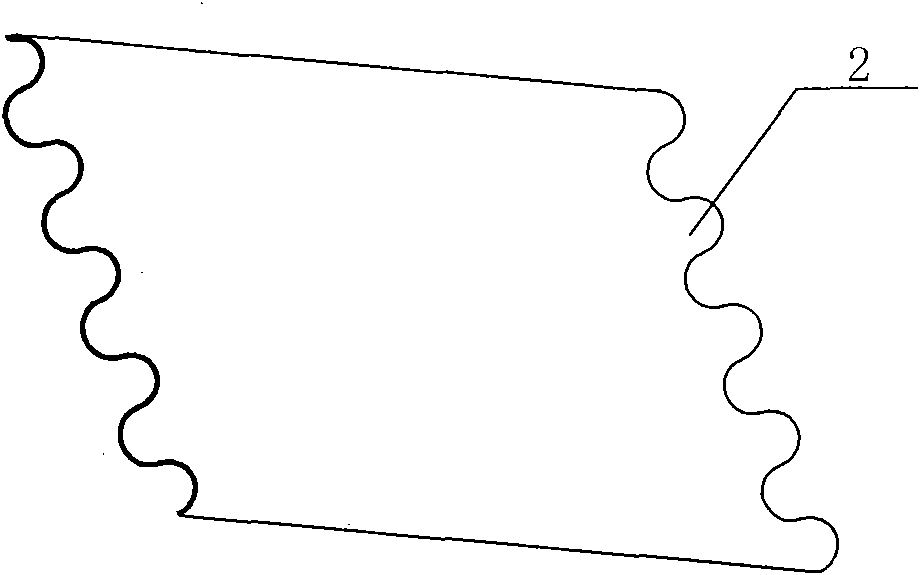

[0012] Specific implementation mode two: refer to Figure 7 The difference between this specific embodiment and the first specific embodiment is that the water curtain 2 can also adopt a wave curve structure in which a circular arc and a straight line are connected tangentially. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com