High-efficiency and large-volume bottom magnetic enrichment device

A large-volume, high-efficiency technology, applied in biochemical cleaning devices, enzymology/microbiology devices, biochemical instruments, etc., can solve problems such as unsatisfactory collection efficiency of aerosols, unfavorable rotating liquid effective wrapping, inconvenient collection of liquid, etc. , to achieve the effect of shortening the enrichment time, increasing the volume and good enrichment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

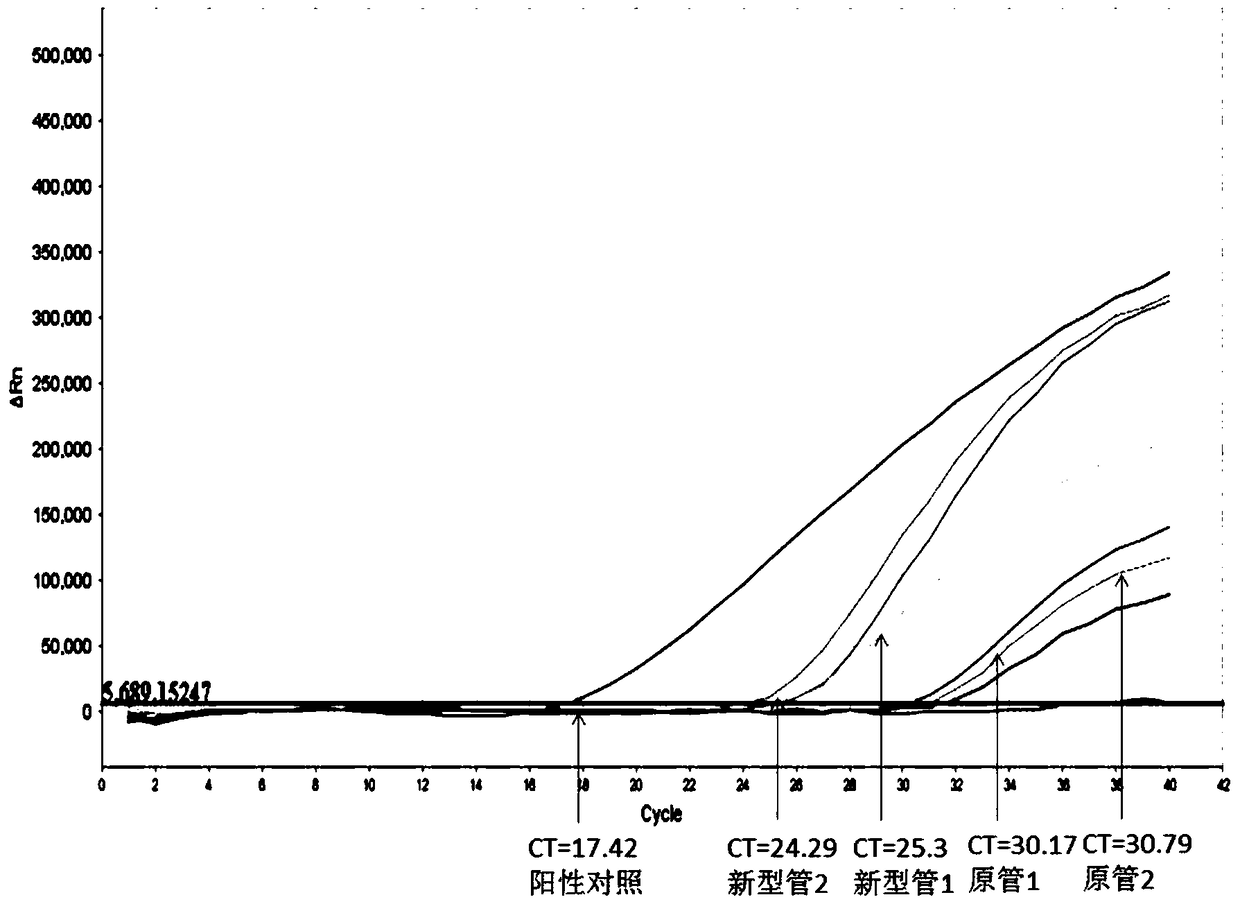

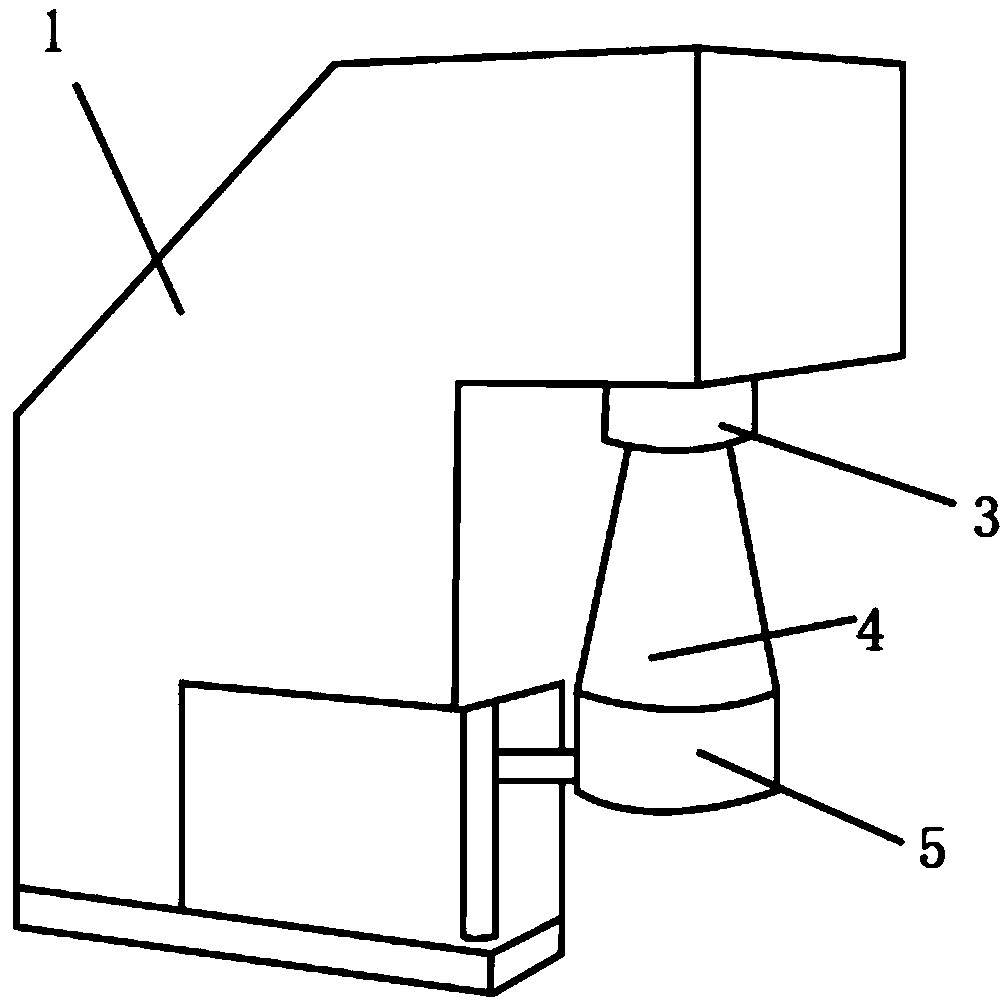

[0037] Example 1 Evaluation of Enrichment Support Magnetic Beads Enrichment Effect

[0038] The old and new sampling cups were used for the magnetic bead enrichment test. First, add an appropriate amount of collection solution to the sampling cup, and then add three drops of magnetic beads (about 150 μl) in the same amount, and stir well to disperse the magnetic beads evenly in the collection solution. Put the sampling cup into the enrichment rack at the same time, and stop the timer. Repeat three times to record the time when the magnetic beads are completely enriched and the collected solution recovers to clear.

[0039] After repeated experiments, the average enrichment time of the bottom enrichment support was 3m24s, and the average enrichment time of the old enrichment support was 5m40s, and the enrichment time was shortened by 40%.

example 2

[0040]Example 2 Evaluation of the recovery effect of the new and old enrichment scaffold magnetic beads

[0041] The old and new sampling cups were used to carry out the magnetic bead recovery comparison experiment. After adding an appropriate amount of collection solution to each sampling cup, add three drops (about 150 μl) of magnetic beads in an equal amount, stir well to mix the magnetic beads evenly, and then carry out enrichment. After the magnetic beads are fully enriched and the collected solution is clarified, rotate the enrichment rack and pour the collected solution to obtain the enriched magnetic beads.

[0042] During the experiment, it was obvious that a small part of the magnetic beads flowed out with the poured liquid in the old-type enrichment scaffold, which caused the loss of biological samples. However, there is no visible loss of magnetic beads in the process of pouring the collection solution at the bottom of the enrichment bracket, which greatly avoids t...

example 3

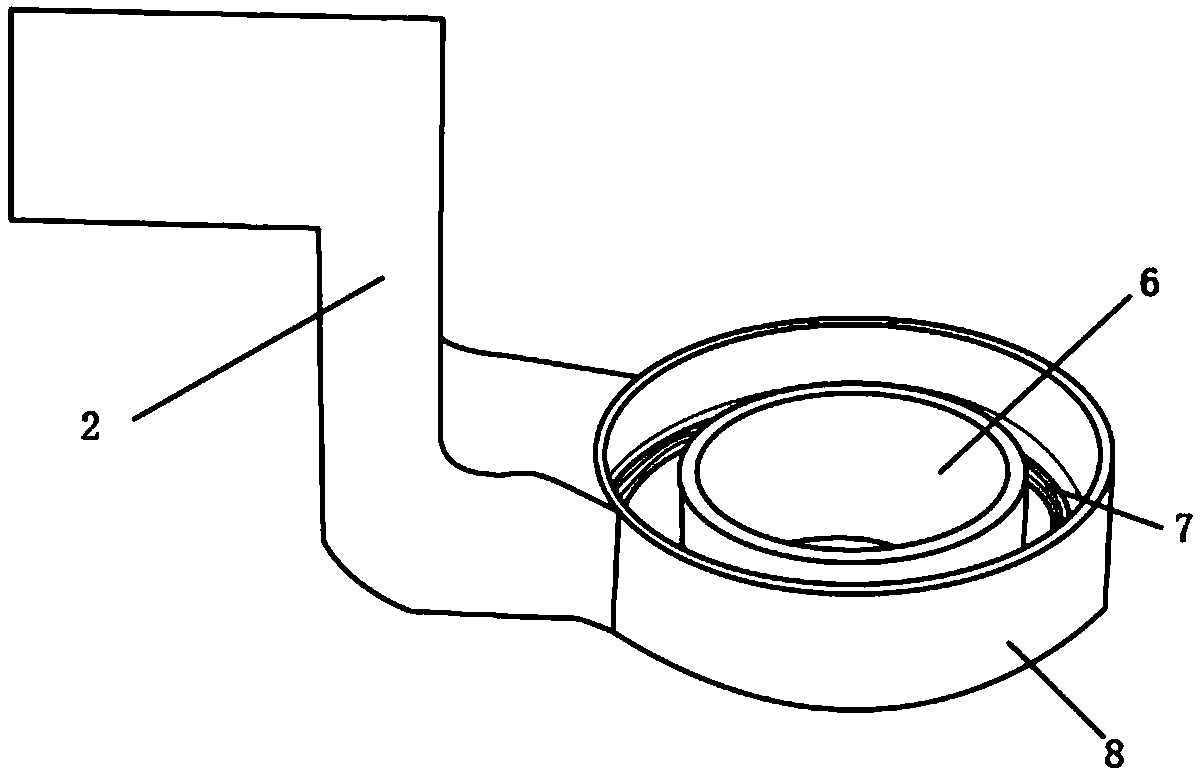

[0043] Example 3 The change experiment of the magnet angle at the bottom of the bottom enrichment support

[0044] Six bottom magnet tilt angles of 110°, 120°, 130°, 140°, 150°, and 160° were designed for the bottom sampling bracket, and the magnetic bead enrichment time evaluation experiment was carried out on them.

[0045] The experiments were repeated three times for each of the six enrichment scaffolds, and the average enrichment time of the six enrichment scaffolds corresponded as follows:

[0046] Bracket angle(°)

[0047] Experiments show that except the enrichment time of 110° and 160° enrichment scaffolds is longer than that of the old-type enrichment scaffolds, the enrichment efficiency of the other four angles of enrichment scaffolds is better than that of the old-type enrichment scaffolds. Therefore, the enrichment bracket at the bottom has good enrichment efficiency within the range of the magnet angle of 120°-150°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com