Bracket for large package of super-thin color tubes of 54cm

A large-package, ultra-thin technology, applied in the field of transportation and packaging of color picture tubes, can solve the problems of excess strength, large average area occupied by a single tube, and high transportation costs, reducing material usage, saving freight, and improving transportation efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

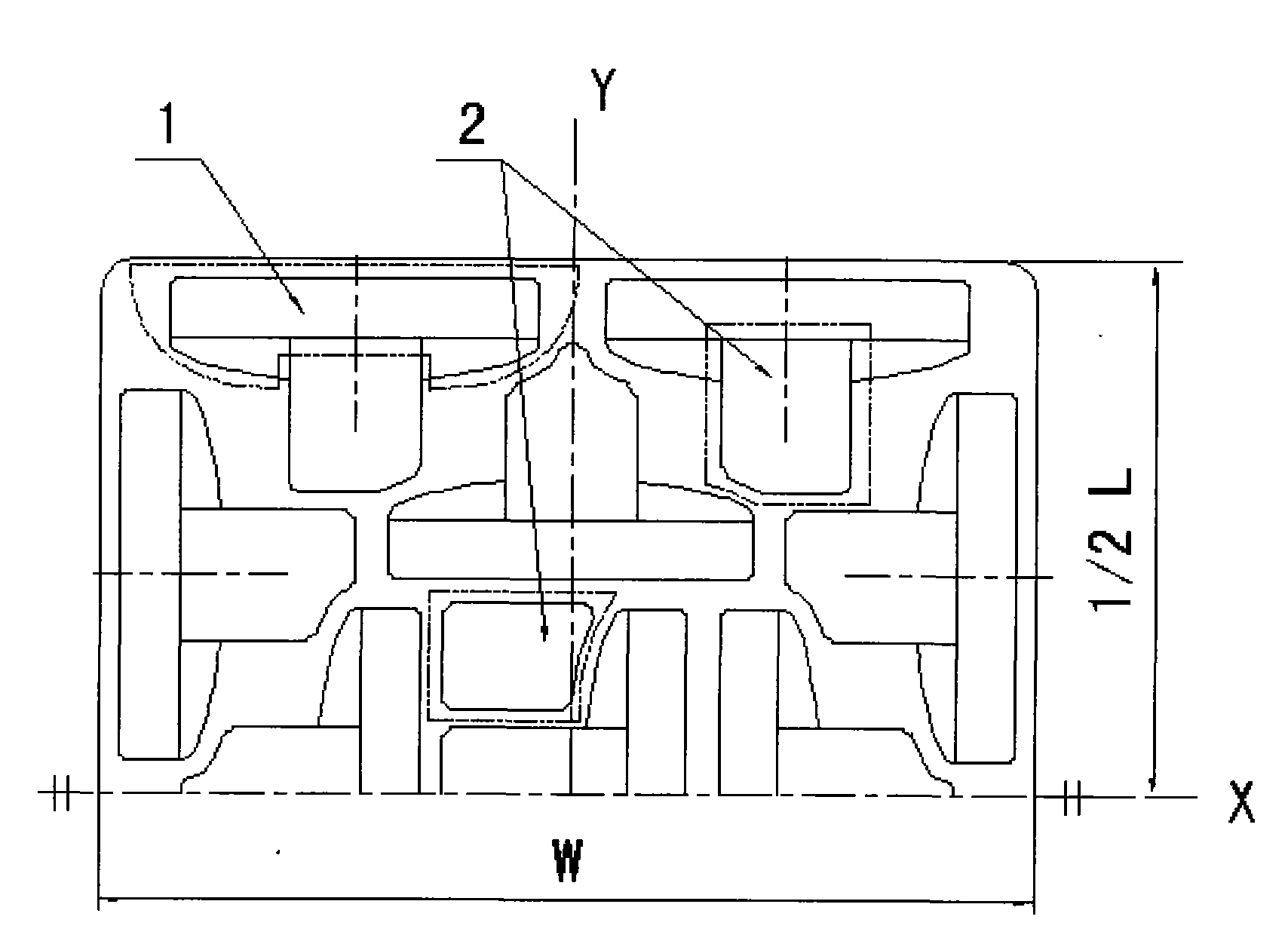

[0012] see figure 1 , a 54cm ultra-thin color tube large packaging bracket, which is thermoplastically formed by a special mold for expandable polystyrene plastic, has a length L of 1290mm, and a width of W of 1135mm. Its upper and lower sides each have 13 A concave color tube-shaped cavity 1 and at least one concave lightening block 2, the color tube-shaped cavity 1 is connected with the lightening block 2.

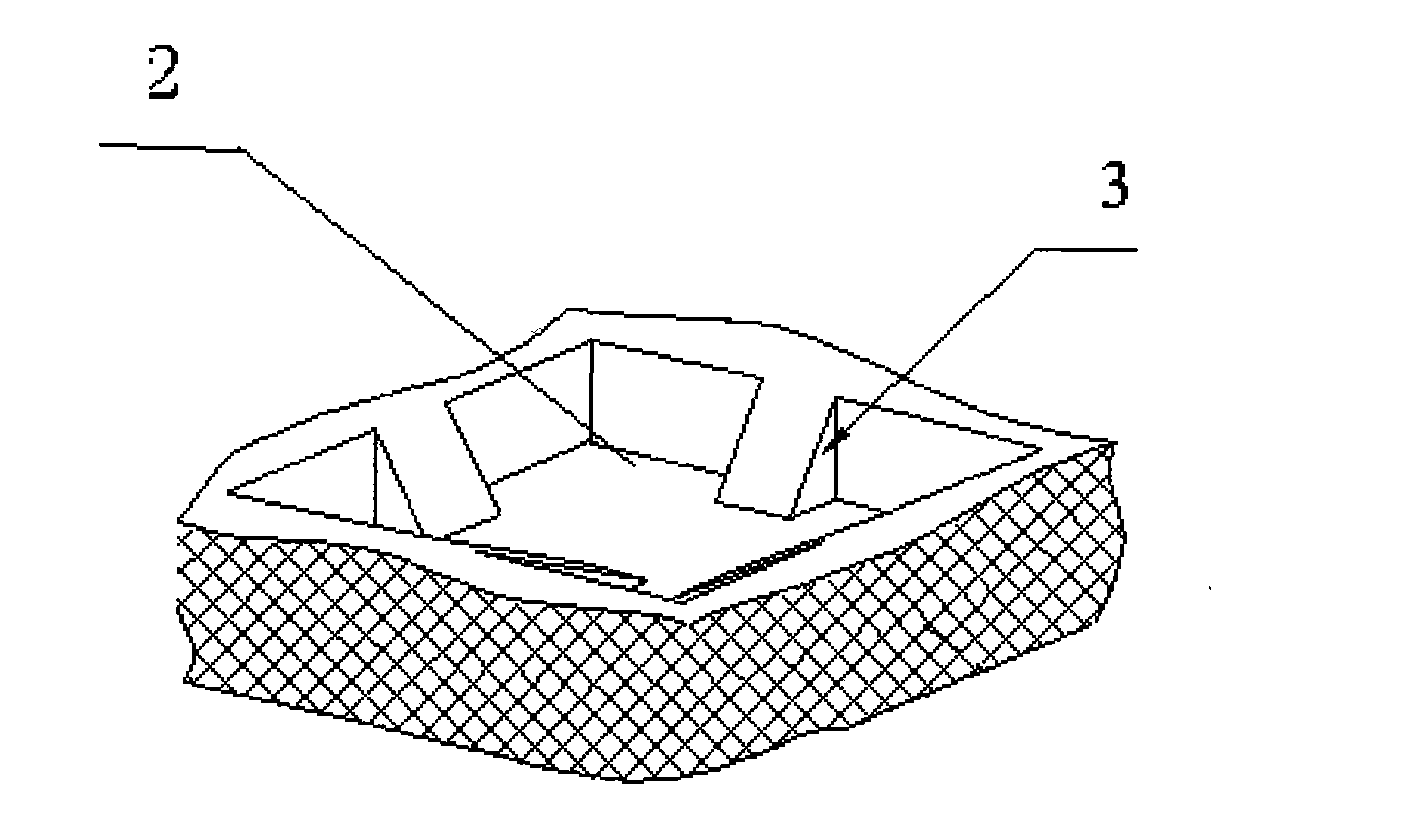

[0013] see figure 2 , The bracket lightening block 2 adopts a characteristic design, and the inner four sides of the lightening block 2 are equipped with right-angled triangle diagonally-stayed reinforcing ribs 3 .

[0014] When in use, the color tube is put into the color tube-shaped cavity 1 of the bracket.

[0015] In the figure: 1 is the color tube cavity; 2 is the lightening block; 3 is the right-angled triangle oblique-stayed rib; L is the length of the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap