Part feeder, and surface mounting machine

A component supply and component technology, applied in the direction of electrical components, electrical components, etc., can solve the problems of difficult to fold back the cover tape, troublesome opening and closing operations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

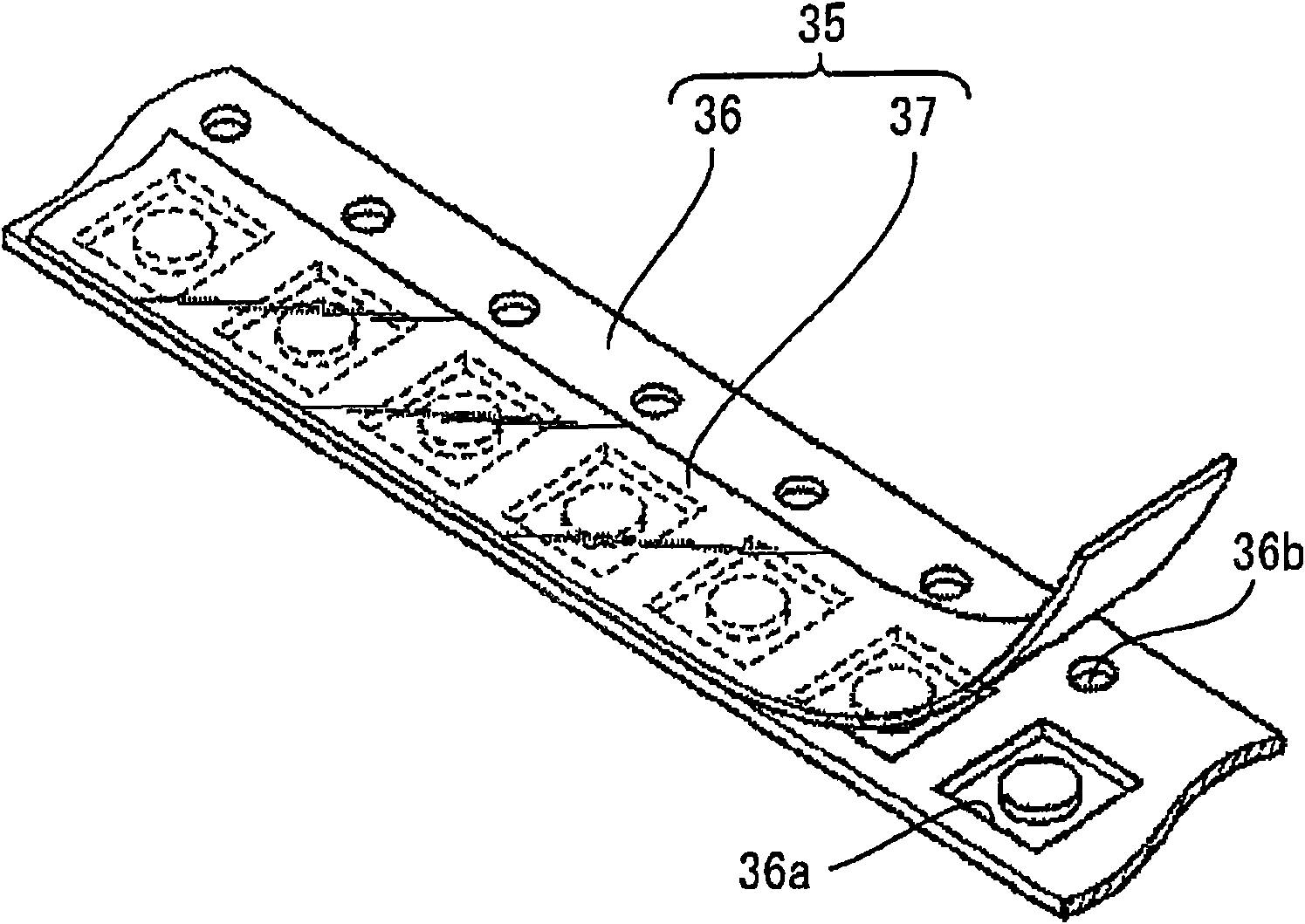

[0027] Below, refer to Figure 1 to Figure 12 , and the first embodiment of the present invention will be described.

[0028] 1. Overall structure

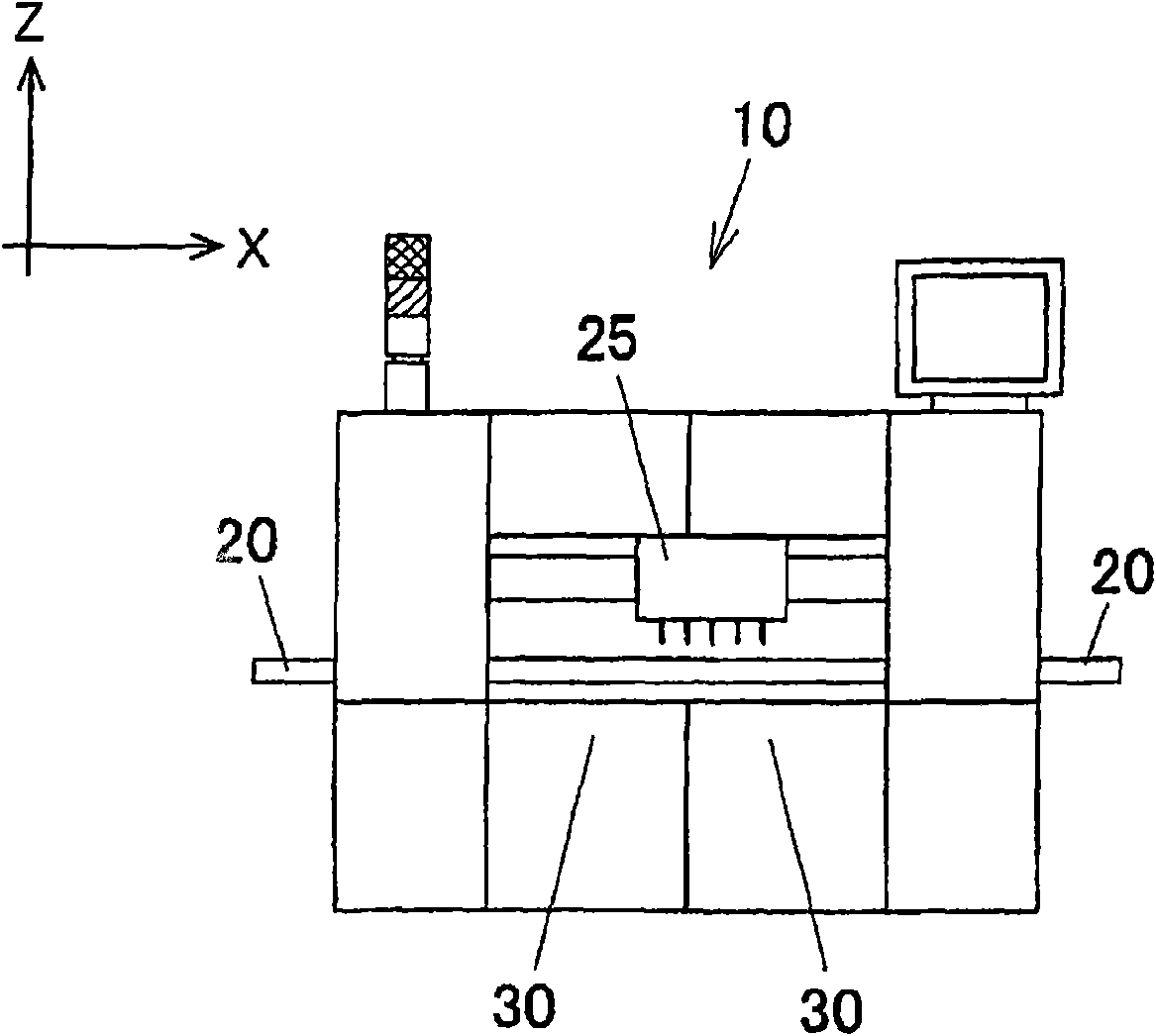

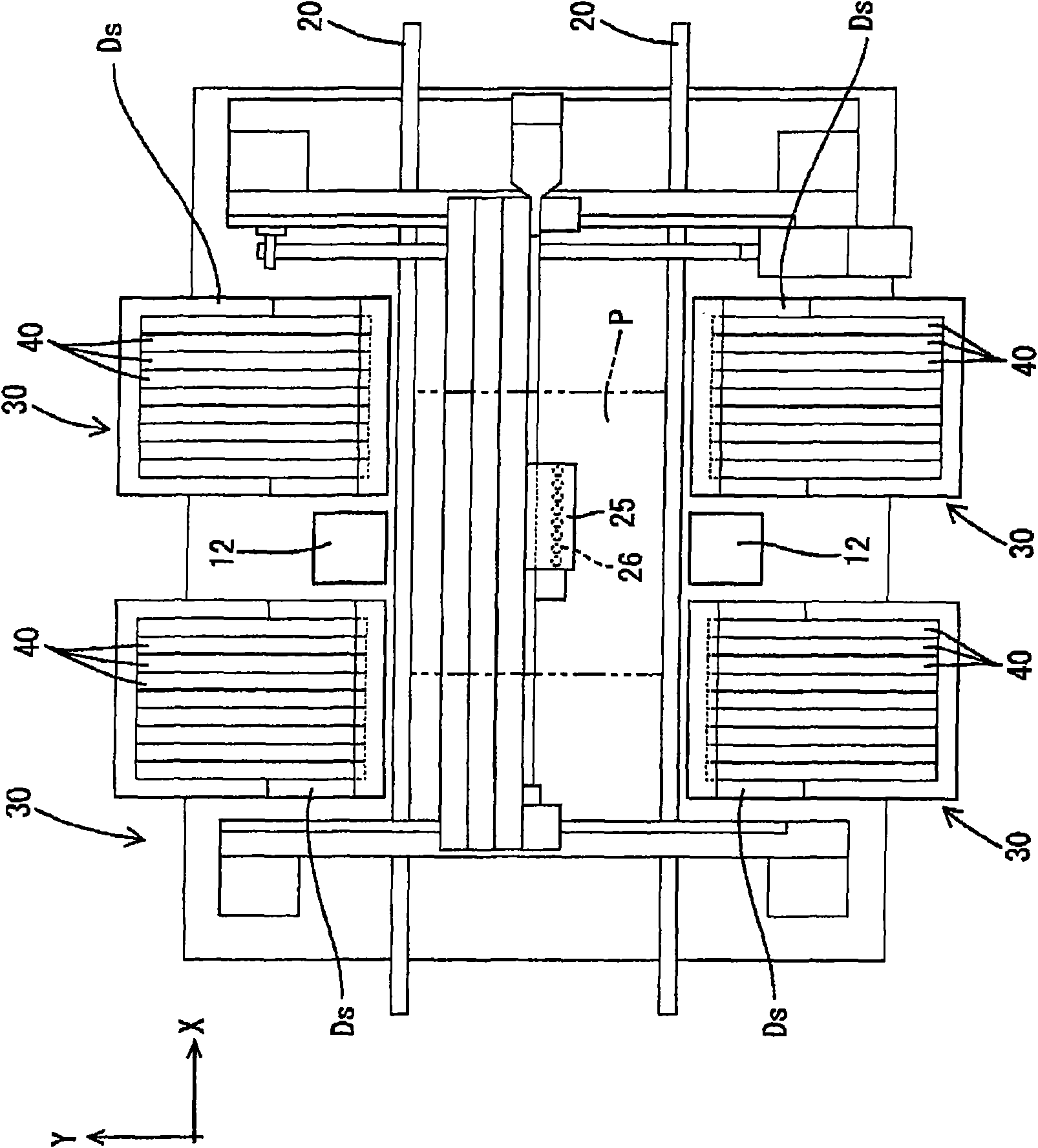

[0029] Such as figure 1 and figure 2 As shown, the surface mounter 10 includes a transfer device 20 for transferring a printed substrate P, component supply units 30 provided on both sides of the transfer device 20 , a head unit 25 , and the like.

[0030] The component supply unit 30 is configured by arranging a plurality of component supply devices 40 in a state of being positioned on a cart Ds, wherein the cart Ds is mounted on the surface in a state of being positioned in the X, Y, and Z directions. The main body of the mounting machine 10.

[0031] The head assembly 25 takes out components from the component supply unit 30 and sends them to the substrate P, and is movable in an area between the component supply unit 30 and the mounting position on the substrate P by driving a drive mechanism such as a servo motor.

[00...

no. 2 Embodiment approach

[0095] Next, a second embodiment will be described.

[0096] In the first embodiment, the component pressing portion 136 is provided on the tape guide 110 , but in the second embodiment, the component pressing portion 136 is eliminated. The shape of the tape guide 200 of the present embodiment is as follows: Figure 13 As shown, except for the element holding portion 136 , the shapes of other portions are the same as those of the first embodiment.

[0097] The element pressing part 136 is a part that restricts the stripping of the element after stripping. When there is no need to worry that the element will come out after stripping, it is also conceivable that the element pressing part 136 does not need to be provided or the element pressing part 136 is not provided. It is an appropriate case (for example, when destaticizing treatment is performed after peeling, etc.).

[0098] Therefore, for example, as long as the tape guide 110 of the first embodiment and the tape guide 2...

no. 3 Embodiment approach

[0101] Next, a third embodiment will be described.

[0102] In the first embodiment, the tape guide 110 is made of resin, but in the third embodiment, the tape guide is reinforced. The shape of the tape guide of this embodiment, such as Figure 14 As shown, the reinforcing plate 220 made of metal is bonded to the left and right side walls 215 of the main body 210 of the tape guide body 210 made of resin by bonding or integrally forming.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com