Integrated drawer guide rail

A guide rail and drawer technology, applied in drawers, furniture parts, household appliances, etc., can solve the problems of complicated production process and increased product volume, and achieve the effect of perfect and reliable functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings.

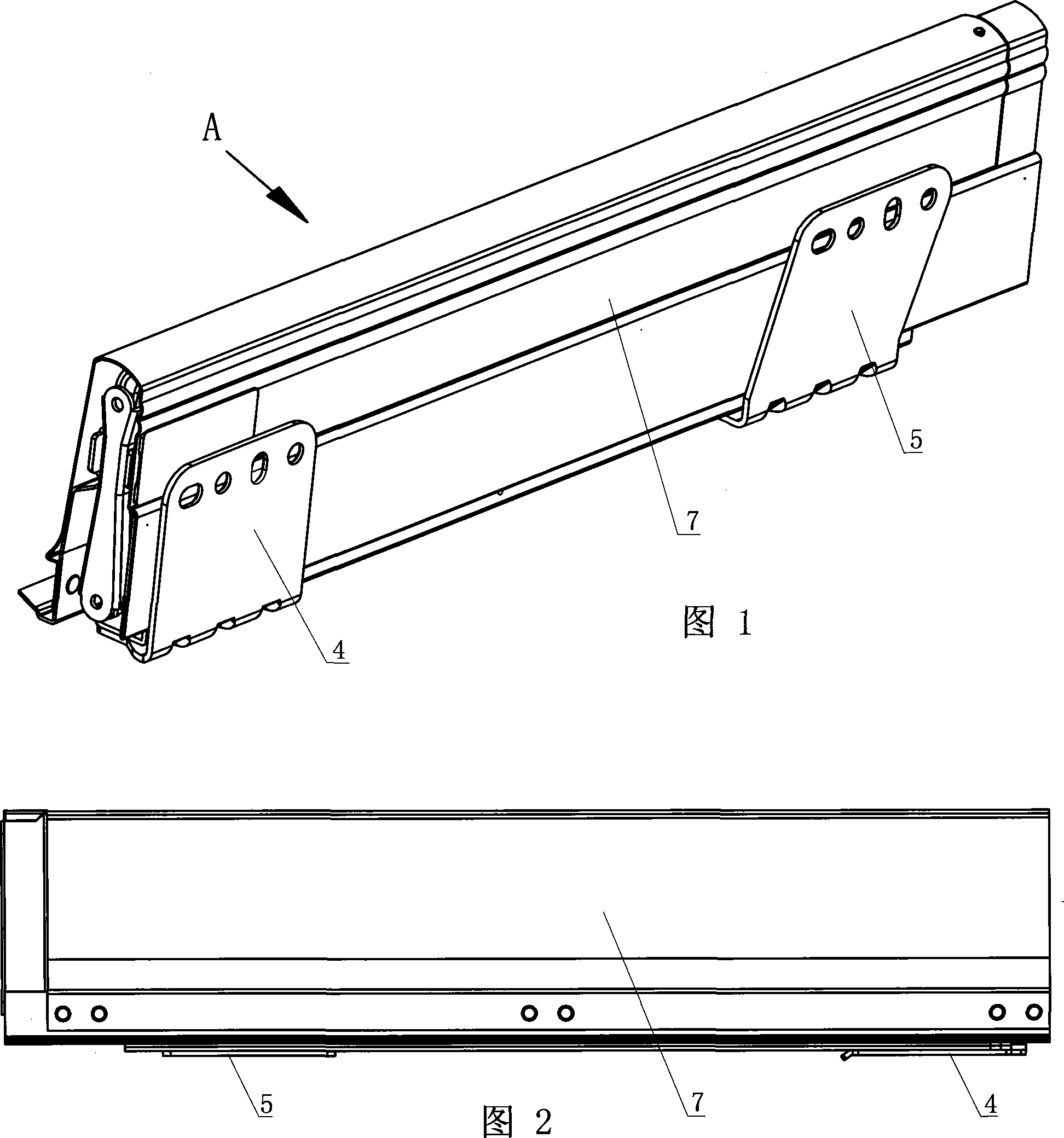

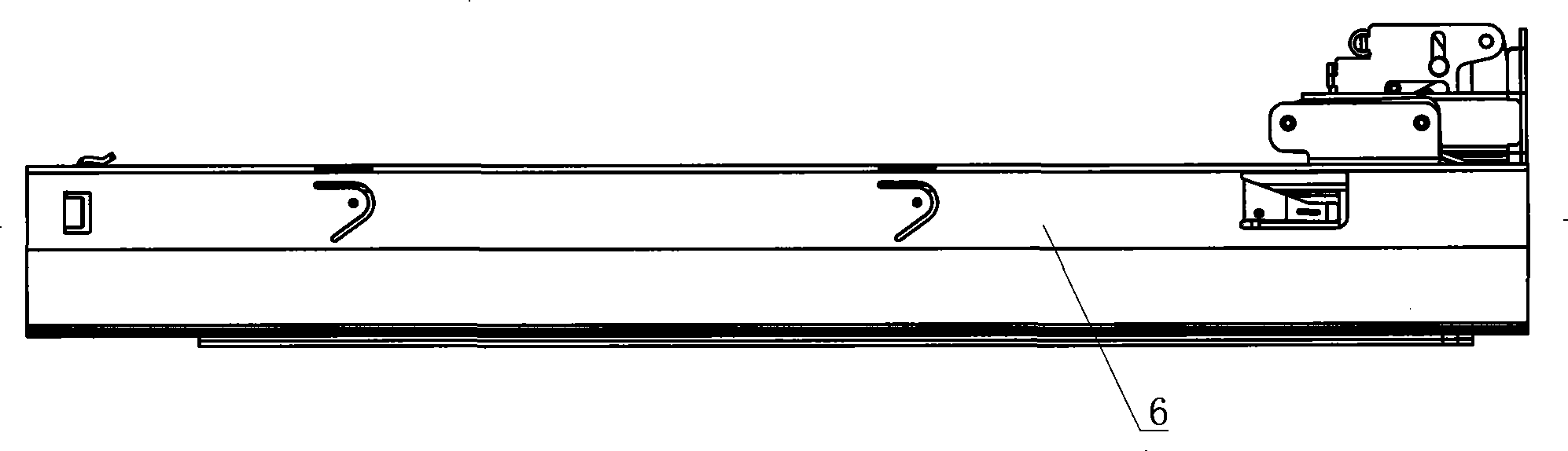

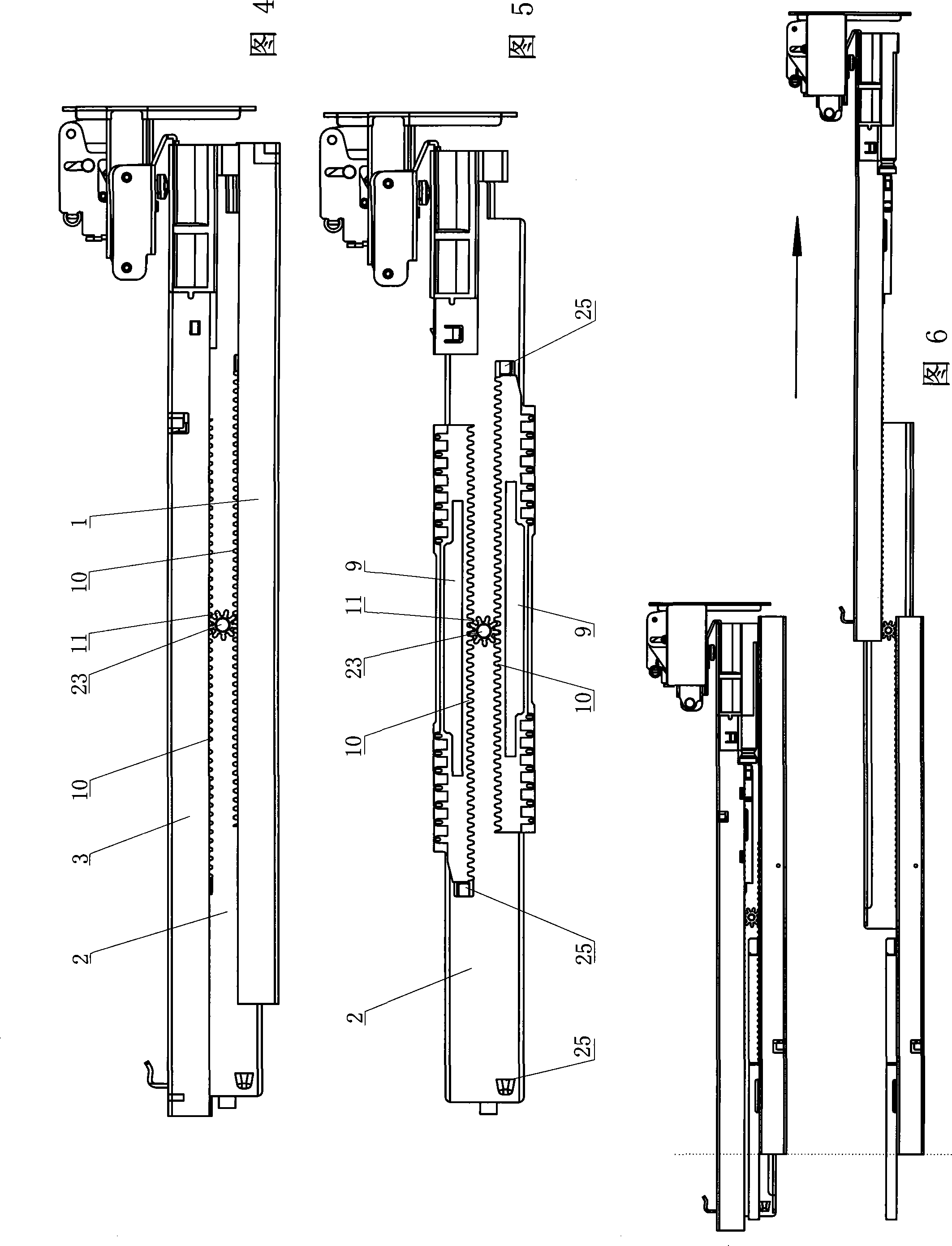

[0036] Referring to Figures 1 to 5, this embodiment has side plates 7, supporting plates 6, front corners 4, rear corners 5, lower rails 1, middle rails 2, upper rails 3, cages 9 and panels in traditional products Connecting device 8 and buffer etc.

[0037] The side plate 7, the supporting plate 6, the front corner bracket 4, the rear corner bracket 5, the lower rail 1, the middle rail 2, and the upper rail 3 are all sheet metal stamping parts; two cages 9 are made of plastic, and one is on the lower rail 1 and the middle rail 2, another piece is between the middle rail 2 and the upper rail 3, and the rollers (not shown) in the cage 9 are in contact with the lower rail 1 and the middle rail 2 or the middle rail 2 and the upper rail 3 at the same time , so that the upper, middle and lower rails are in a rolling fit; a rack 10 is formed on the edge of the cag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com