A Spindle Feed Mechanism of a Digital Radial Drilling Machine

A technology of radial drilling machine and feeding mechanism, which is applied in the parts of boring machine/drilling machine, drilling/drilling equipment, metal processing machinery parts, etc. Complete and reliable, simple and reasonable structure, convenient and quick operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

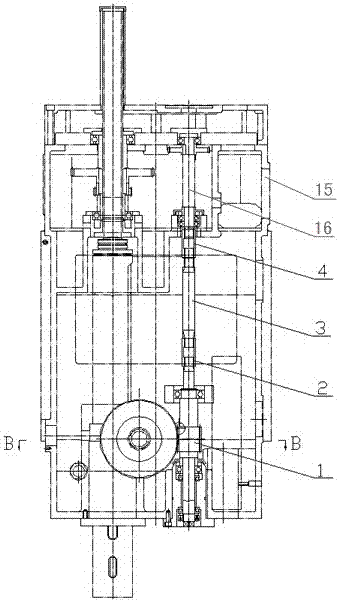

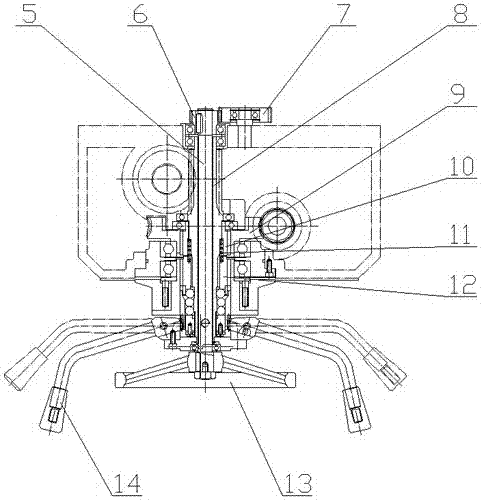

[0012] Referring to the accompanying drawings, a spindle feed mechanism of a digital radial drilling machine is composed of a horizontal shaft and a worm shaft. The horizontal shaft includes a mandrel 5, a first gear 6, a second gear 7, and a third gear 8 , worm gear 9, first clutch 10, spring 11, second clutch 12, hand wheel 13, handle 14, gearbox 15, the first gear 6 is set on the top of the mandrel 5, the first gear 6 meshes with the second gear 7 , the second gear 7 is installed on the gearbox 15, the third gear 8 is set in the middle of the mandrel 5, the first worm gear 9 is set on the middle bearing of the mandrel 5, and the second clutch 12 is installed in the middle bearing hole of the mandrel 5 , the first clutch 10 is installed in the hole of the worm wheel 9, the spring 11 is installed in the inner hole of the first clutch 10 and the second clutch 12, and a hand wheel 13 and a handle 14 are set at the bottom of the mandrel 5; the worm shaft includes a worm 1, The f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com