Main shaft and balance mechanism of digital display type radial drilling machine

A technology of balance mechanism and radial drilling machine, which is applied in the direction of large fixed members, metal processing machinery parts, maintenance and safety accessories, etc. It can solve the problems of poor limit function, backward control system, and difficult to realize, and achieve complete functions and reliability. Advanced control system, simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

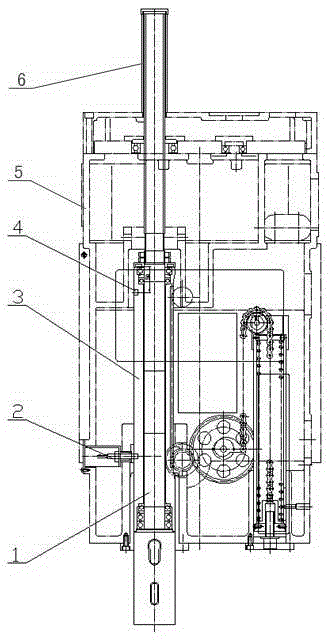

[0011] Referring to the attached drawings, a digital display type radial drilling machine main shaft and balance mechanism, including main shaft 1, proximity switch 2, main shaft sleeve 3, non-ferromagnetic material induction block 4, gearbox 5, spline sleeve 6, in the gearbox A proximity switch 2 is set on 5, a main shaft sleeve 3 is set on the bearing of the main shaft 1, a non-ferromagnetic material sensing block 4 is installed on the main shaft sleeve 3, and a spline sleeve 6 is installed on the upper part of the main shaft 1.

[0012] The working principle of the spindle and balance mechanism of a digital radial drilling machine is that a non-ferromagnetic material induction block 4 is installed in the hole on the spindle sleeve 3. When the proximity switch 2 of the spindle 1 moves to the non-inductive block 4. The generator signal realizes the limit function of the upper and lower limits of the main shaft and the balance mechanism. The vertical layout of the main shaft 1 req...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com