Installation mechanism of closestool lid

A technology of installation mechanism and toilet cover, which is applied in the field of sanitary ware products, can solve the problems affecting the appearance of the toilet, affecting the improvement of product grade, and the length of the toilet cover, so as to achieve easy assembly and disassembly, upgrade of product grade, and good overall appearance sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

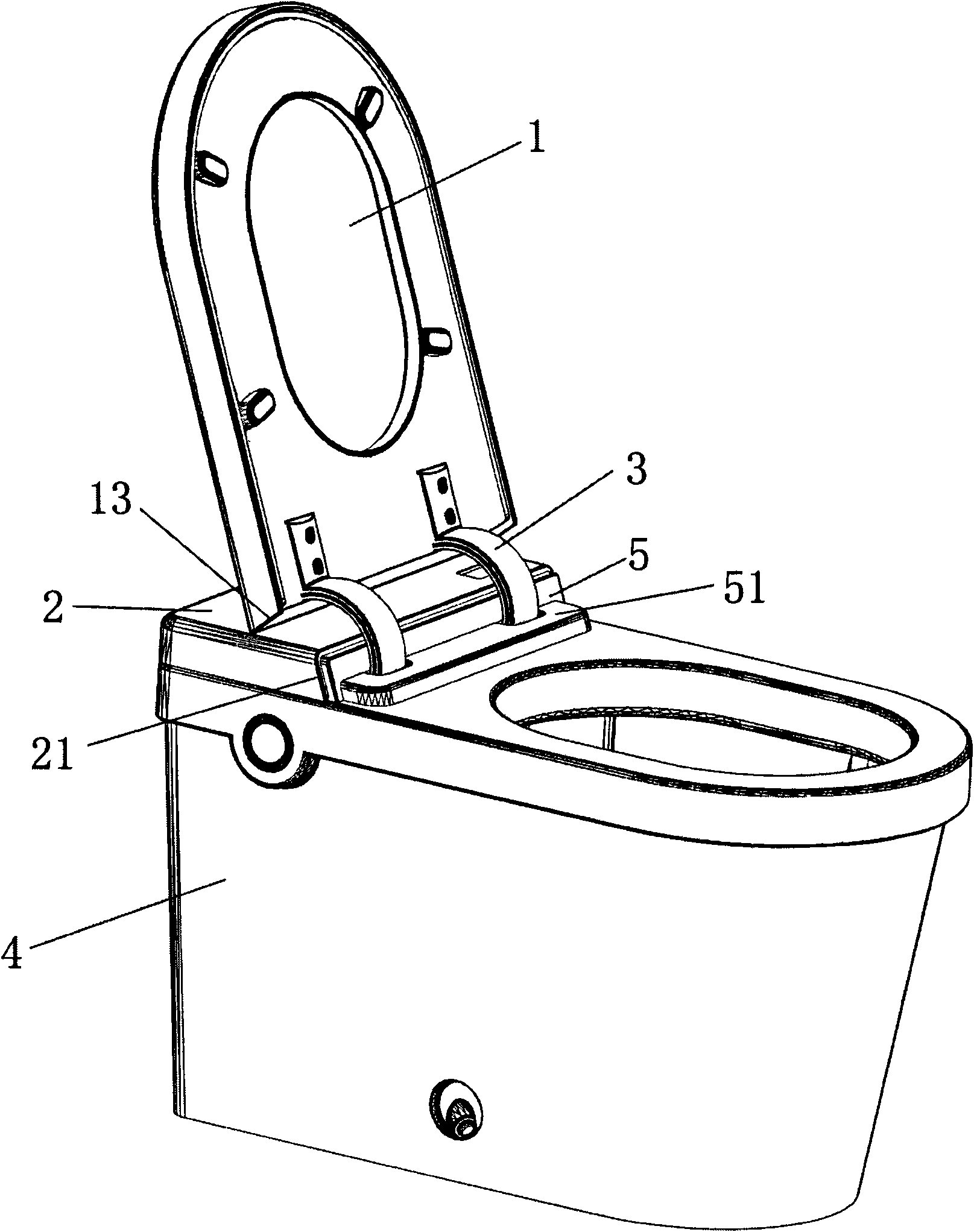

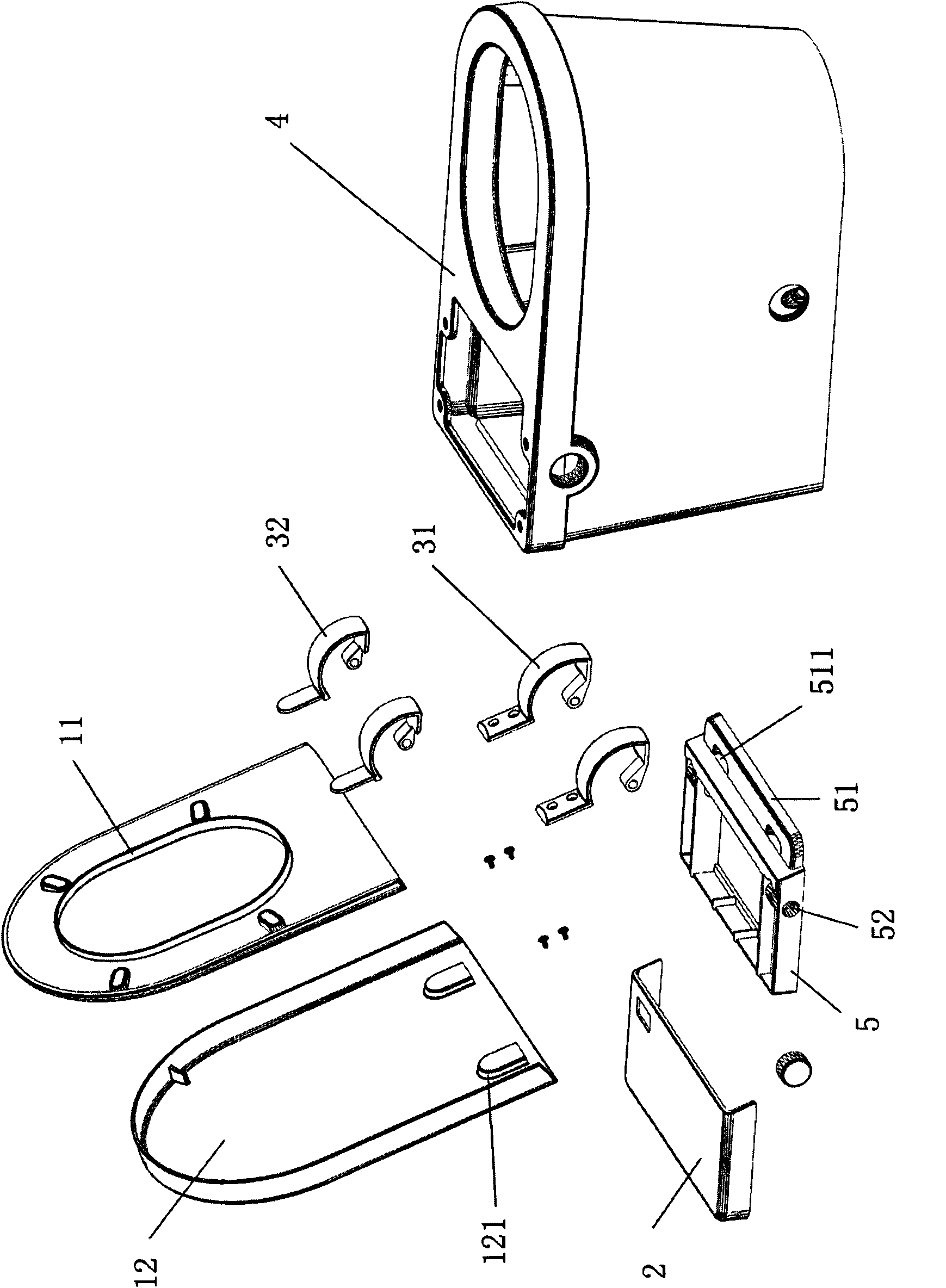

[0032] Referring to the accompanying drawings, the installation mechanism of a toilet cover of the present invention includes:

[0033] A toilet cover 1 is arranged on the front upper end of the toilet seat 4; the toilet cover 1 includes a seat ring 11 and an upper cover 12, and the seat ring 11 and the upper cover 12 can be stacked together and rotate relative to the toilet seat 4 , can also be separated to rotate respectively relative to the toilet seat 4;

[0034] A back cover body 2 is fixed on the rear upper end of the toilet seat body 4, the front end edge 21 of the back cover body 2 abuts against the rear end edge 13 of the toilet cover plate, and the toilet cover plate 1 and the back cover body 2 jointly cover the entire upper surface of the toilet seat 4;

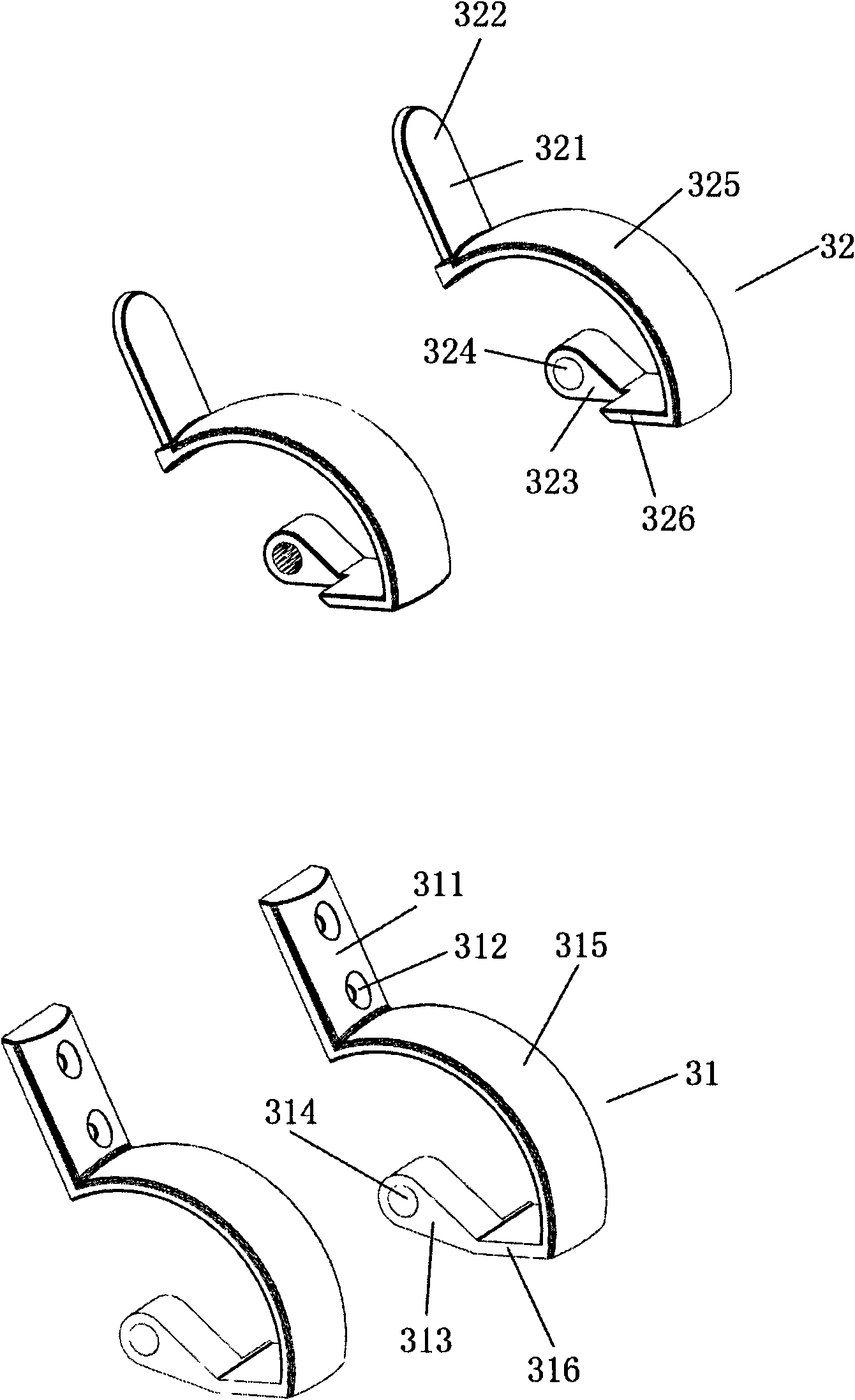

[0035] The rotating shaft mechanism is installed in the back cover body 2 and has a proper length distance from the front end of the rear cover body 2; since the rotating shaft mechanism is not the design focus of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com