Leather needle eye tearing test fixture and test method thereof

A test fixture and test method technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the problem of slipping of round rods, inability to accurately reflect the stress of leather, and inability to measure leather tension, etc. problem, to achieve the effect of low cost, simple structure and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

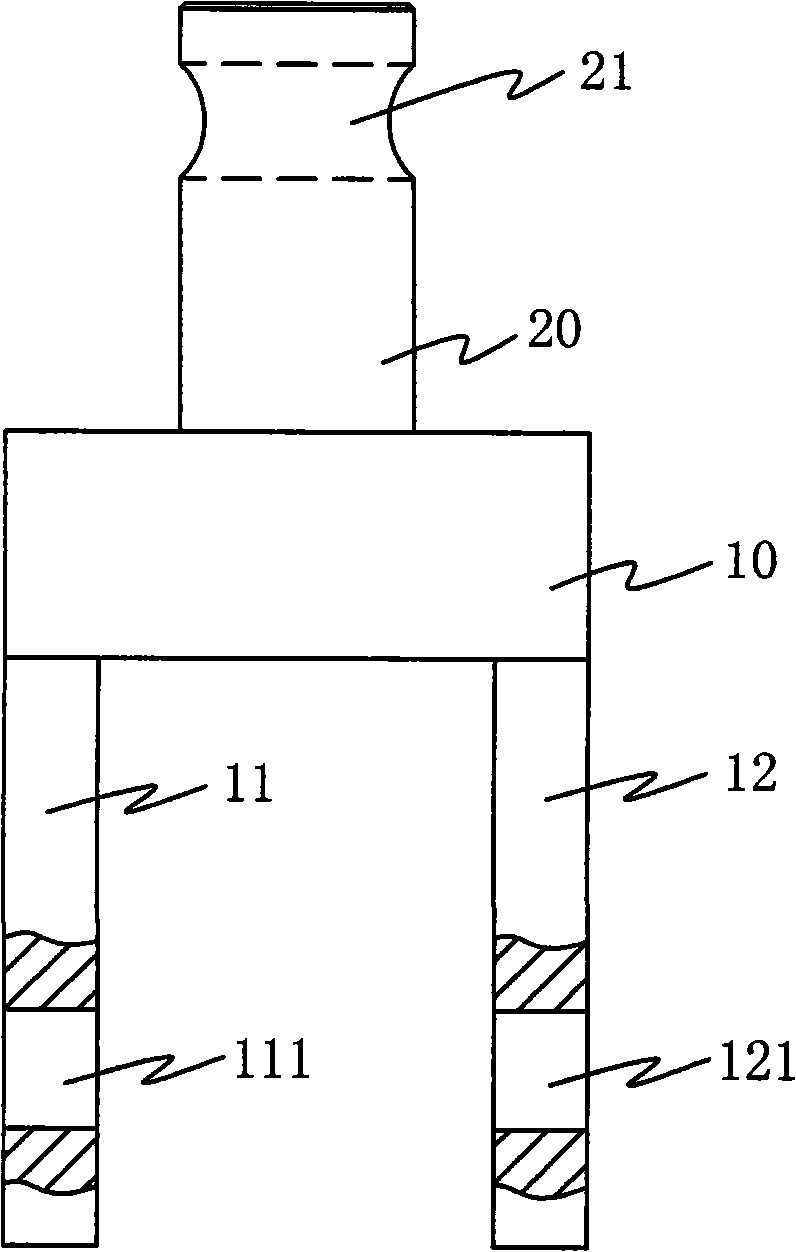

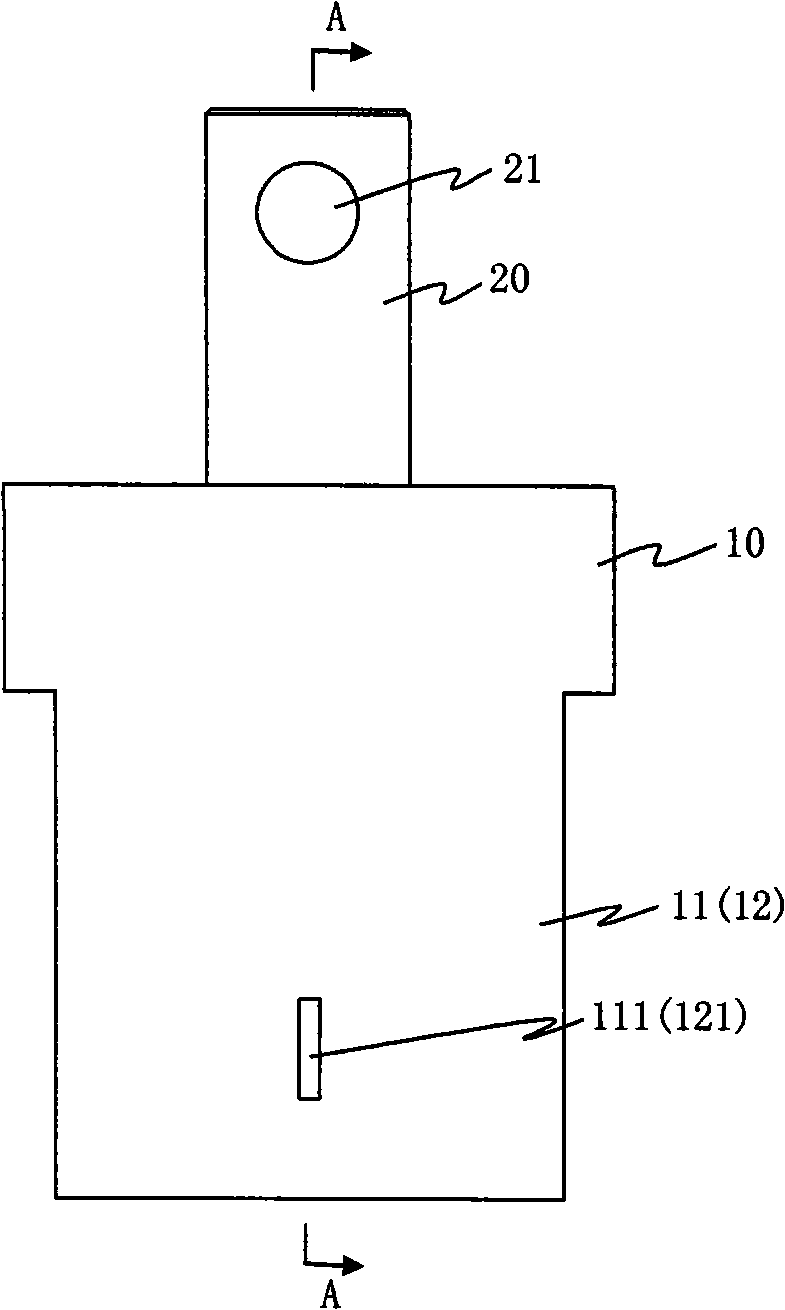

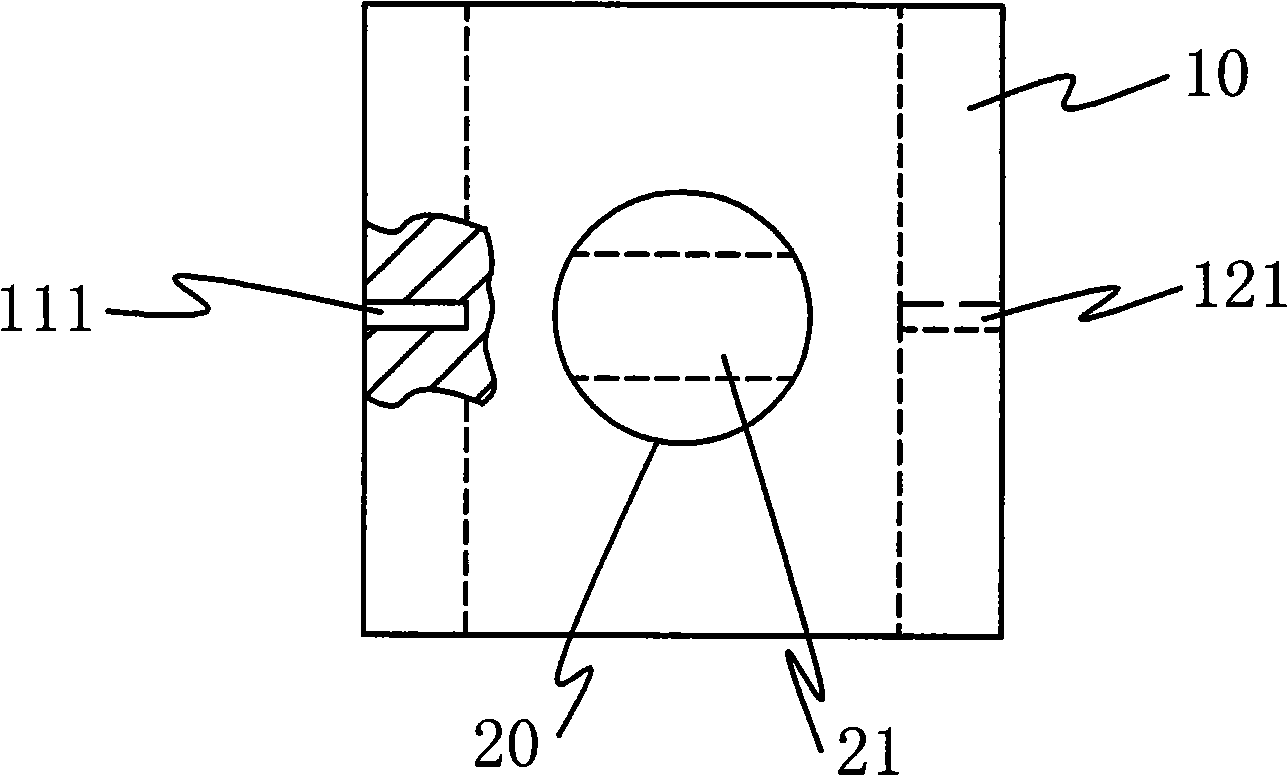

[0014] A leather pinhole tear test fixture, comprising a chuck 10 composed of first and second clamps 11 and 12, the clamp 10 is U-shaped, and the first and second clamps 11 and 12 are provided with pins for use 30 through the first and second through holes 111, 121, such as figure 1 shown.

[0015] combine figure 1 , 2 , 3, 4, the first and second clamps 11 and 12 are two plates with parallel plates, and the plates of the first and second clamps 11 and 12 are respectively provided for the passage of pins 30 The first and second through holes 111, 121. The chuck 10 is provided with a cylindrical body 20 upwards, and a third through hole 21 is opened on the cylindrical body 20 to cooperate with the upper jaw of the tensile machine. The clamp is installed and fixed on the tensile machine through the cylindrical body 20, and the tensile machine drives the clamp to move upward. . "Upward" referred to in the present invention refers to the moving direction of the tensile machi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap