Electric connector safety choke plug capable of changing an initiating explosive device resistor

A technology for electrical connectors and pyrotechnics, which is applied in the direction of connection, parts and circuits of connecting devices, and can solve problems such as waste and scrapping of connectors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

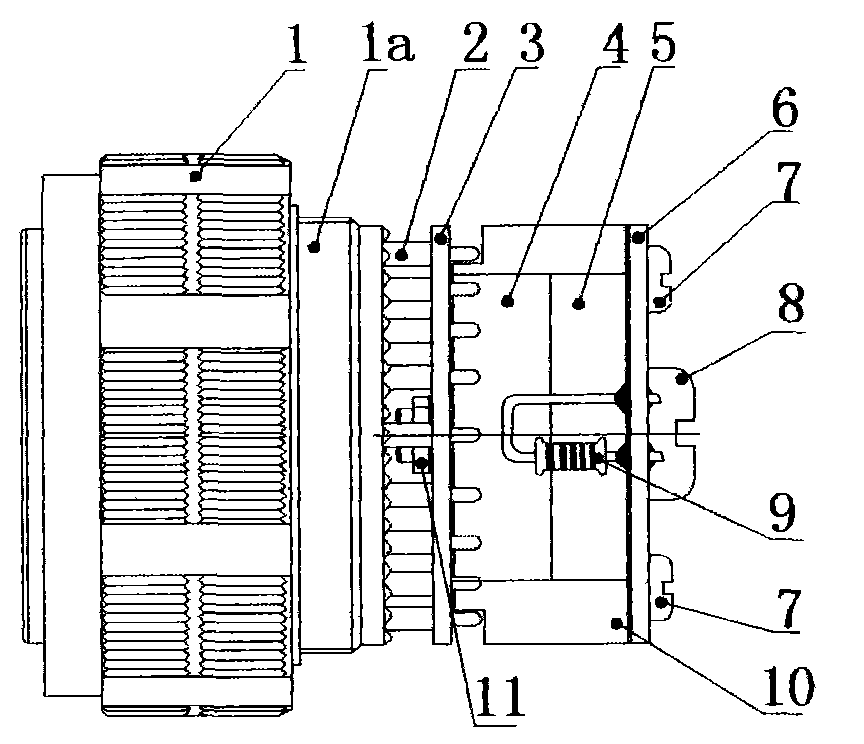

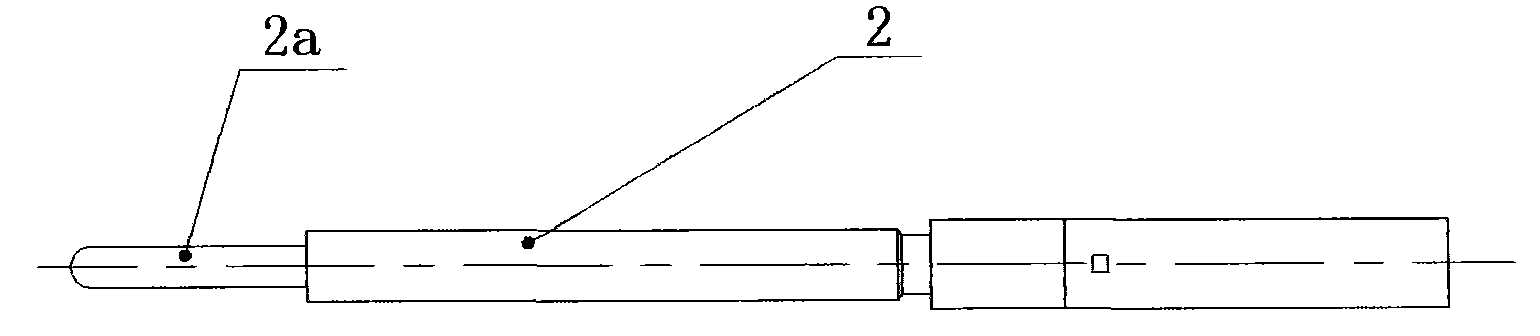

[0016] figure 1 It is a structural schematic diagram of Embodiment 1. As shown in the figure, the safety plug is composed of a connector 1, a printed board jack assembly 2, a first printed board 3, a second printed board 6, a pin connector 4, Hole connector 5, protective cover 10, pyrotechnics resistance 9, wherein the tail of the printed board socket assembly 2 is provided with a step, and the tail of the printed board socket assembly 2 is provided with a step 2a, and its front end is connected to the connector 1 The holes are docked, and the first printed board 3 is welded at the tail step 2a. Considering the structural strength of the first printed board 3, its thickness is designed to be 2mm; the size and thickness of the second printed board 6 are the same as those of the first printed board. 3 are the same, the pin connector and the hole connector are welded and fixed on the first and second printed boards respectively, and the pyrotechnics resistance is also welded and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com