Heat-exchanging device

A technology of heat exchange equipment and baffles, applied in lighting and heating equipment, heat exchanger types, direct contact heat exchangers, etc., can solve the problems of insufficient cooling effect and long cooling time, and achieve structural Simple, good heat exchange effect, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below, the present invention will be described in further detail through the description of specific embodiments in conjunction with the accompanying drawings, but this is not a limitation of the present invention. Those skilled in the art can make various modifications or improvements according to the basic idea of the present invention, but as long as they do not depart from The basic idea of the present invention is within the scope of the present invention.

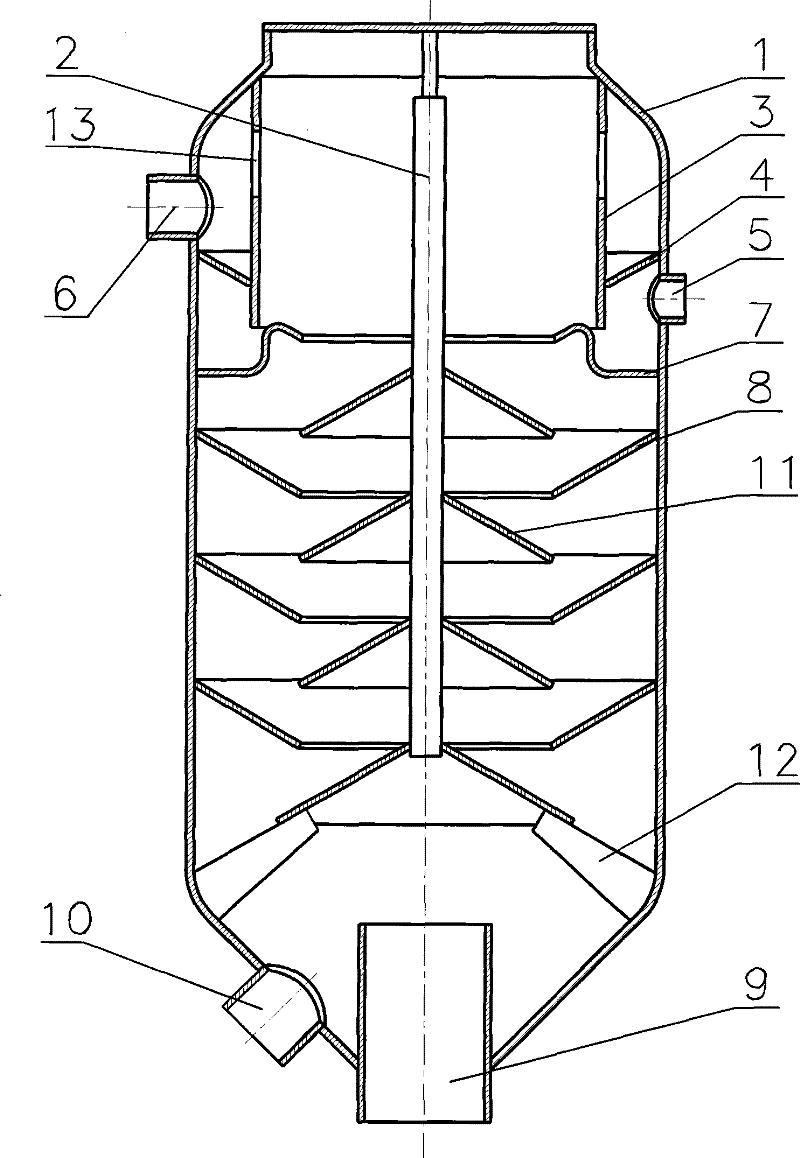

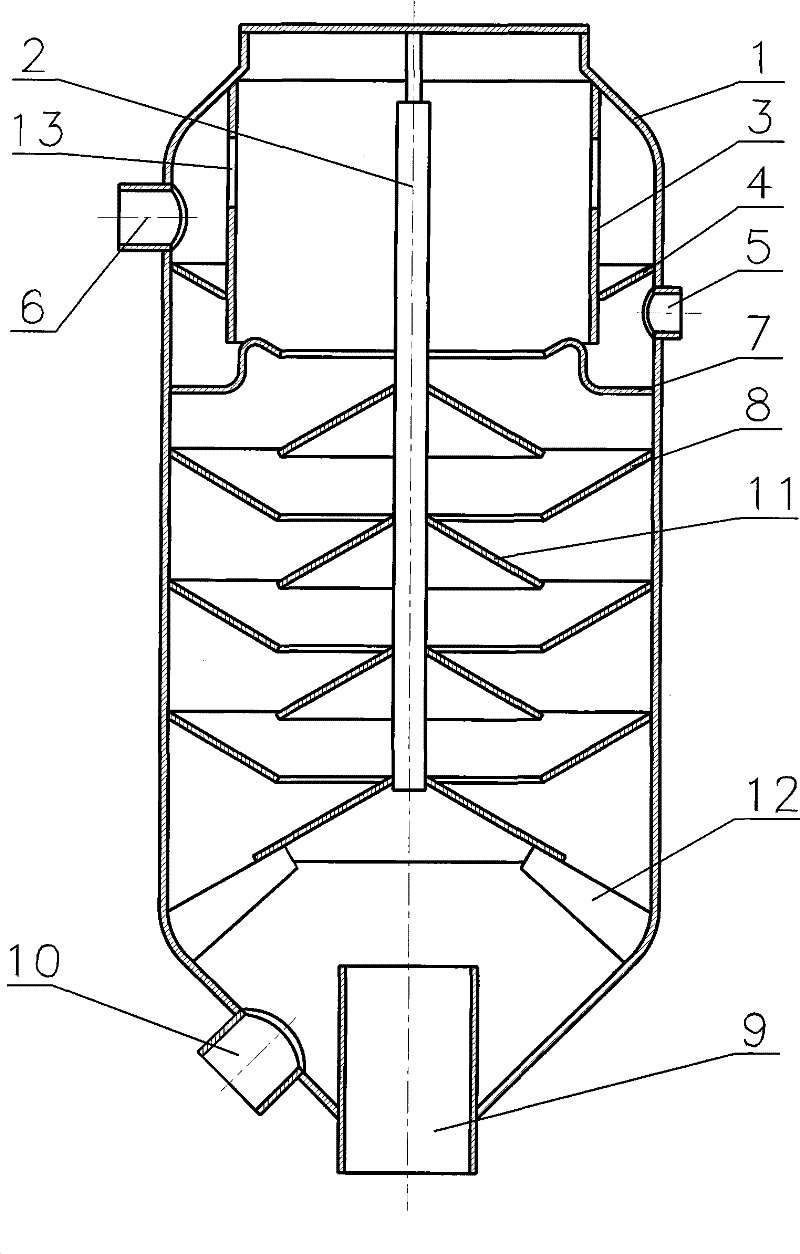

[0026] As shown in the figure, a heat exchange device of the present invention includes a tank body 1, a cylindrical baffle 3 is arranged on the upper part of the tank body 1, and an opening 13 is arranged on the cylinder wall of the cylindrical baffle 3, and the cylindrical baffle 3 The middle and lower part of the plate 3 is welded with a baffle 4, the shape of which is a hollow cone. The air port 6 and the air outlet 6 communicate with the opening 13 on the cylindrical baffle 3, and an overflow plate 7 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com