Modeling method of non-axisymmetrical hub for improving blockage at angular region

A non-axisymmetric, hub technology, used in non-variable volume pumps, components of pumping devices for elastic fluids, machines/engines, etc., can solve the problem of no structural modeling, no quantitative expression, pumping Questions about stomatal reliability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

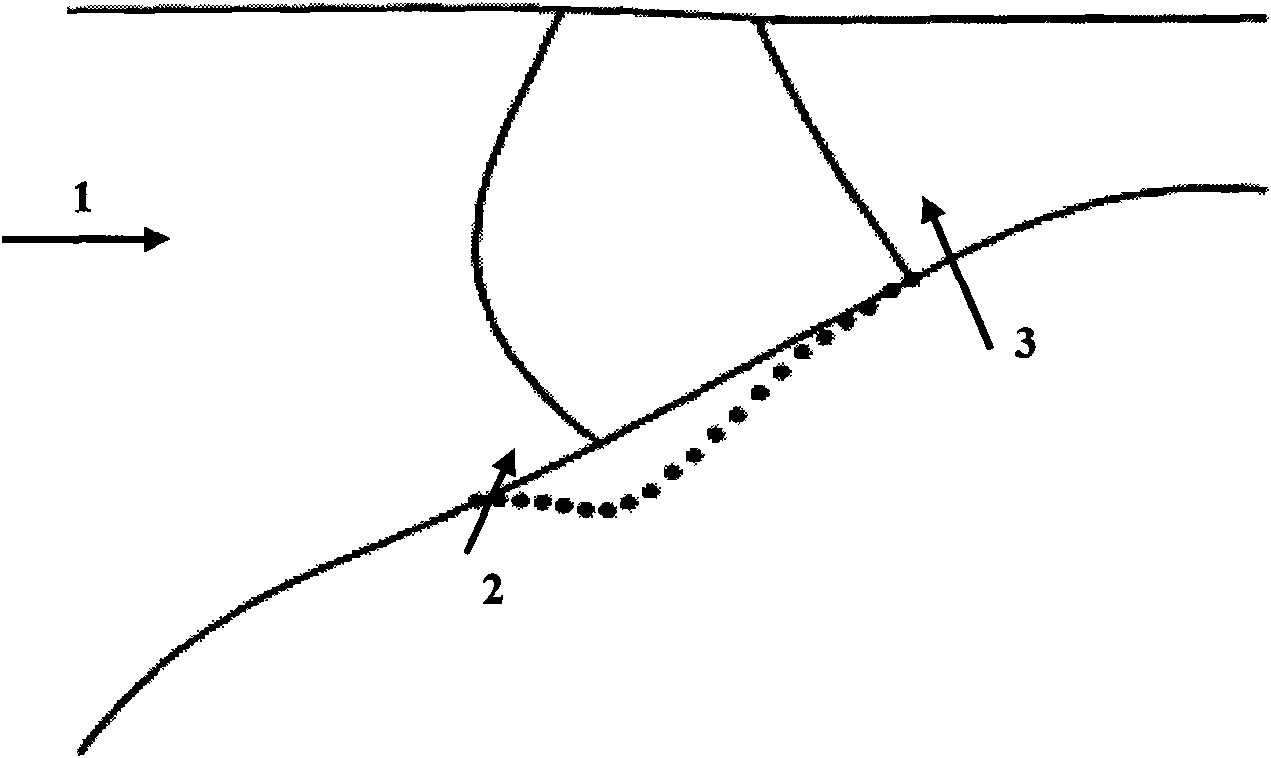

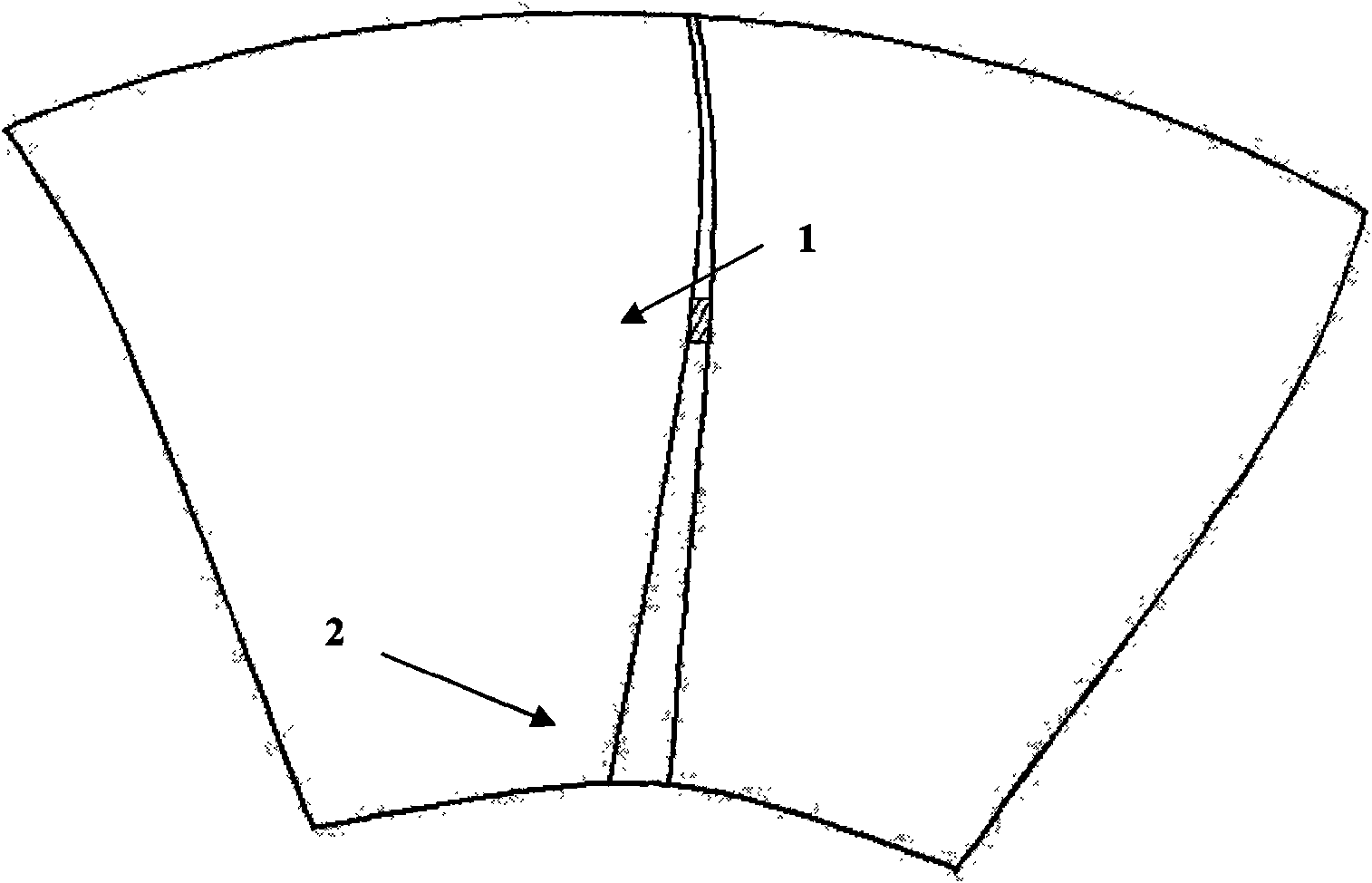

[0026] The specific embodiment of the present invention is illustrated with examples. A fan rotor hub is redesigned according to the above-mentioned non-axisymmetric hub modeling method for improving corner blockage.

[0027] The design parameters of the fan rotor are shown in Table 1, and the blade surface parameters are known data.

[0028] Table 1 Design parameters of axial fan rotor

[0029]

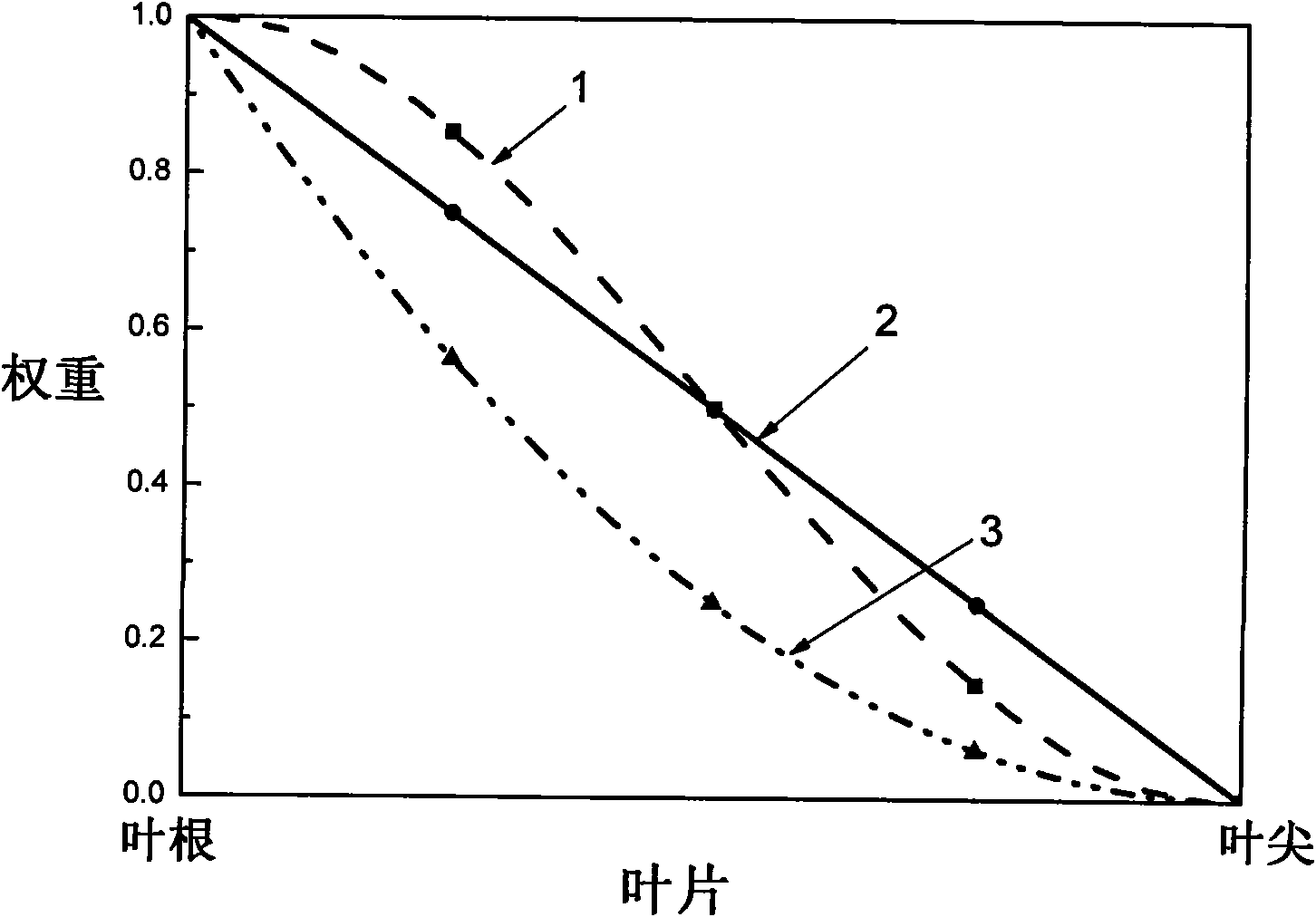

[0030] 1. Determine the concave amplitude ΔR of the hub along the axial direction according to method (1):

[0031] 1) Take the calculation of the cross-sectional area of the blade at z=0 as an example. It is known that the blade surface data is composed of 86 points on the pressure surface at the primitive level, 86 points on the suction surface, and 21 primitive levels in the radial direction. The two coordinates corresponding to z=0 of the pressure surface and the suction surface of each primitive level can be obtained by the method of difference, so 42 coordinate points c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com