Automatic grafting machine

An automatic grafting and driving cylinder technology, which is applied in the field of agricultural machinery, can solve problems such as difficult to achieve precise alignment operation of mechanisms, insufficient speed and displacement of working parts, and influence on cutting accuracy of seedlings, etc., to achieve stable grafting quality, convenient operation, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

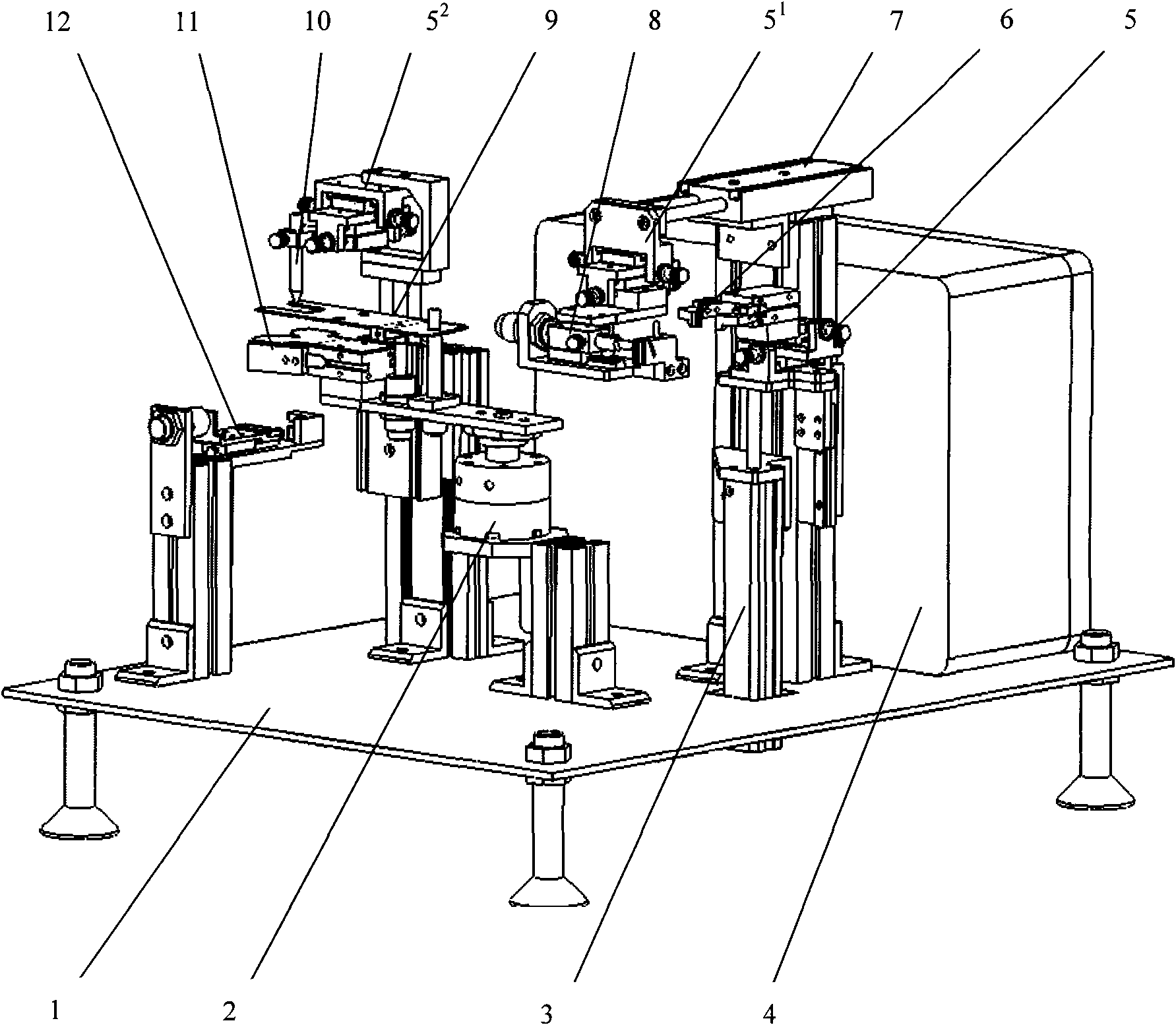

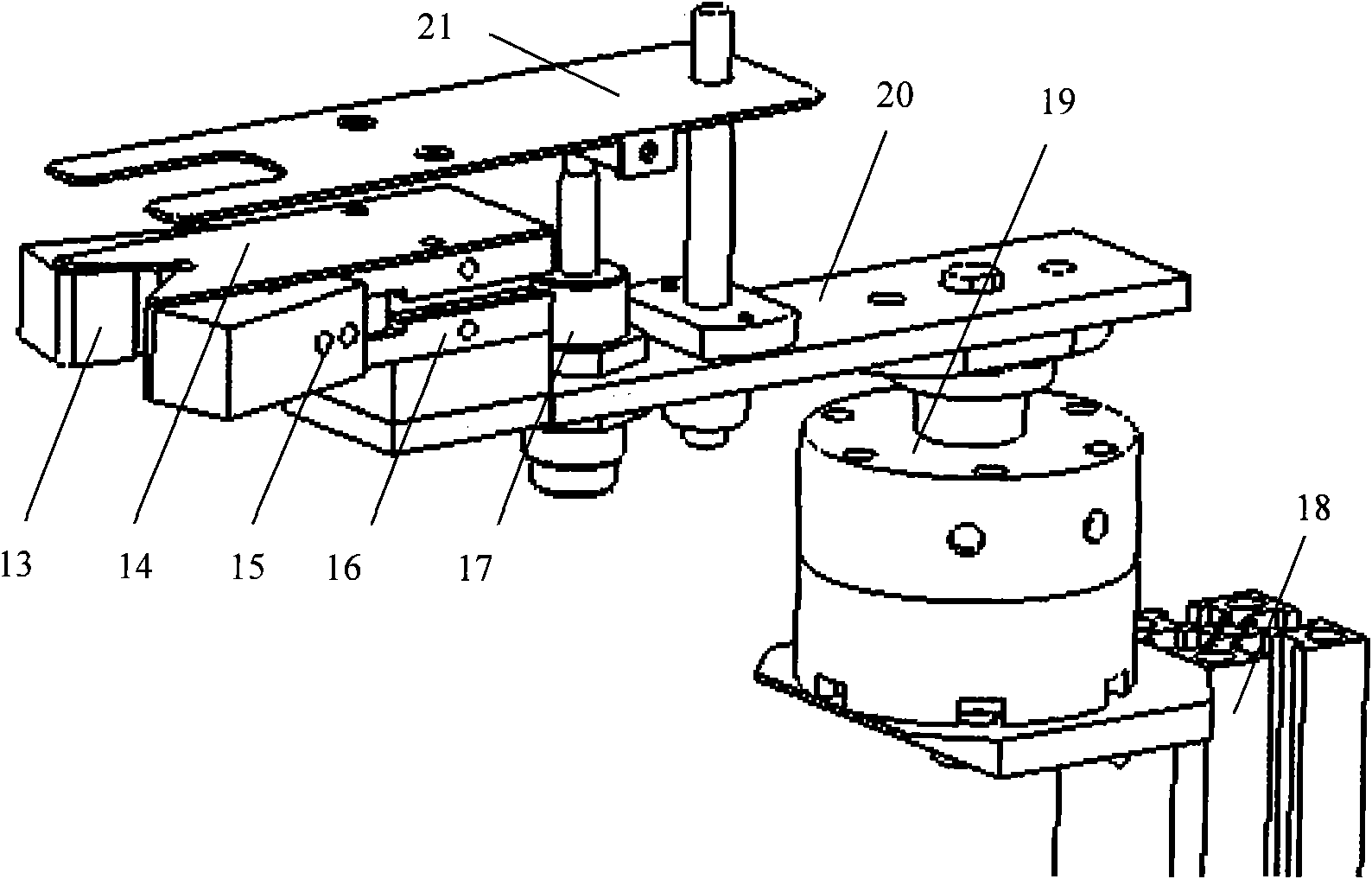

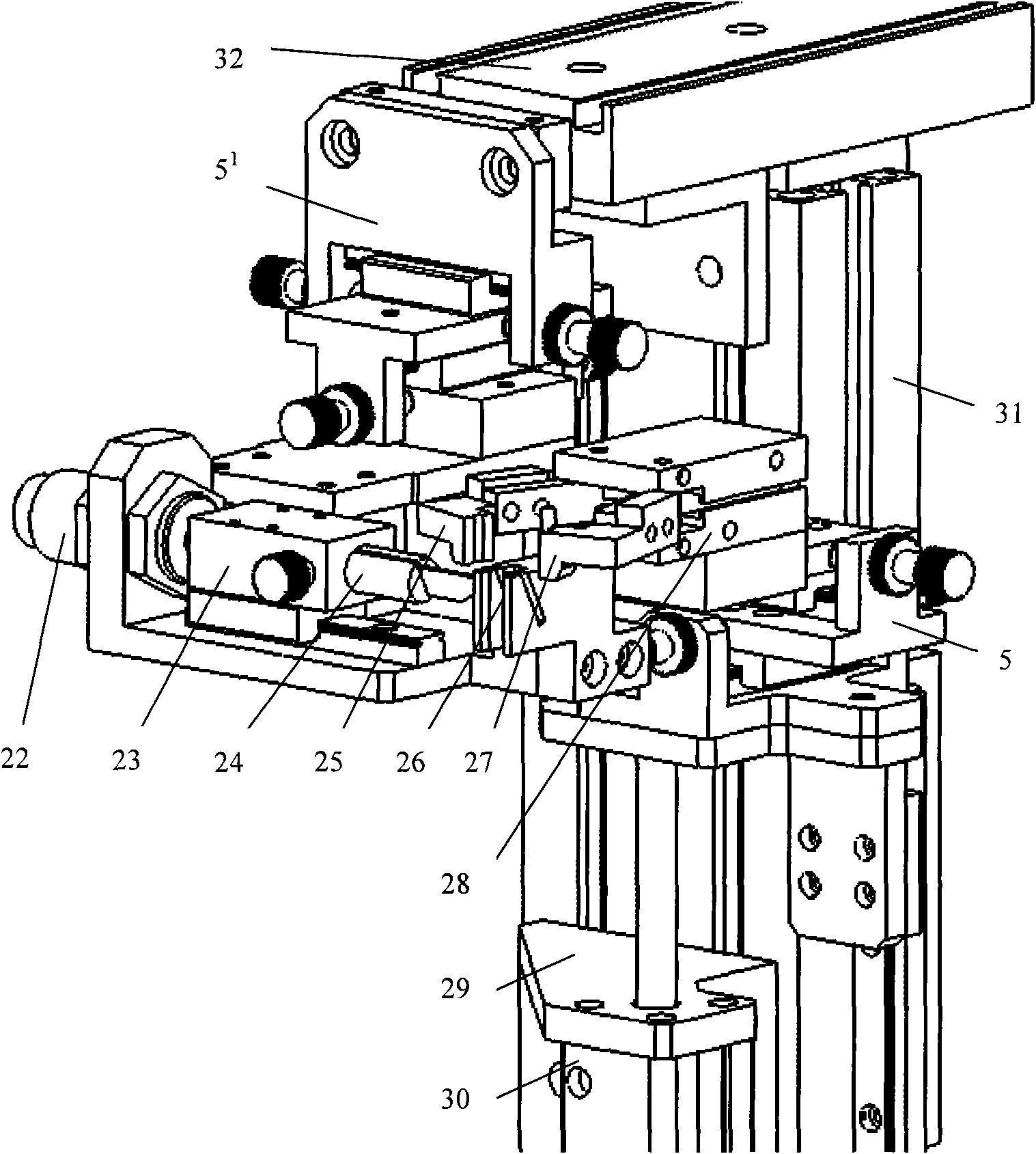

[0024] Such as figure 1 Shown, a kind of automatic grafting machine, it comprises rotating arm mechanism 2, and this rotating arm mechanism 2 is fixedly installed on the base plate 1, and rootstock clip 11 and rootstock cotyledons seedling pressing mechanism 9 are installed successively on rotating arm mechanism 2.

[0025] At the initial position of the rotating arm mechanism 2, that is, the seedling position on the rootstock, the rootstock punching mechanism 10 is installed above the rootstock clamp 11, and the rootstock root removal mechanism 12 is installed below; at the position where the rotating arm mechanism 2 rotates 180 degrees, that is, the grafting position of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com