Method and device for laminating edge margin rubber sheets at reverse side of air retaining liner rubber sheet

An airtight layer and film technology, applied in the field of tire manufacturing, can solve the problems of increasing the production cost of production line equipment, large installation and operation space, and low production efficiency, so as to achieve small installation space, improve production efficiency, and reduce production costs. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

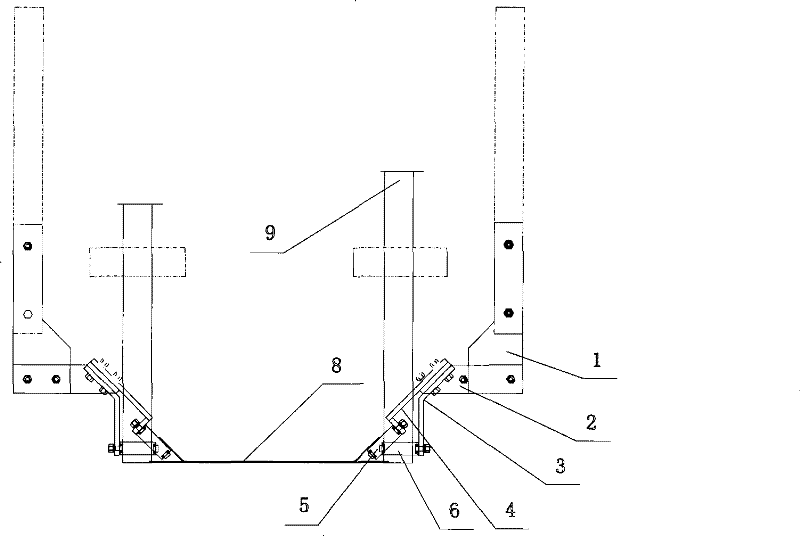

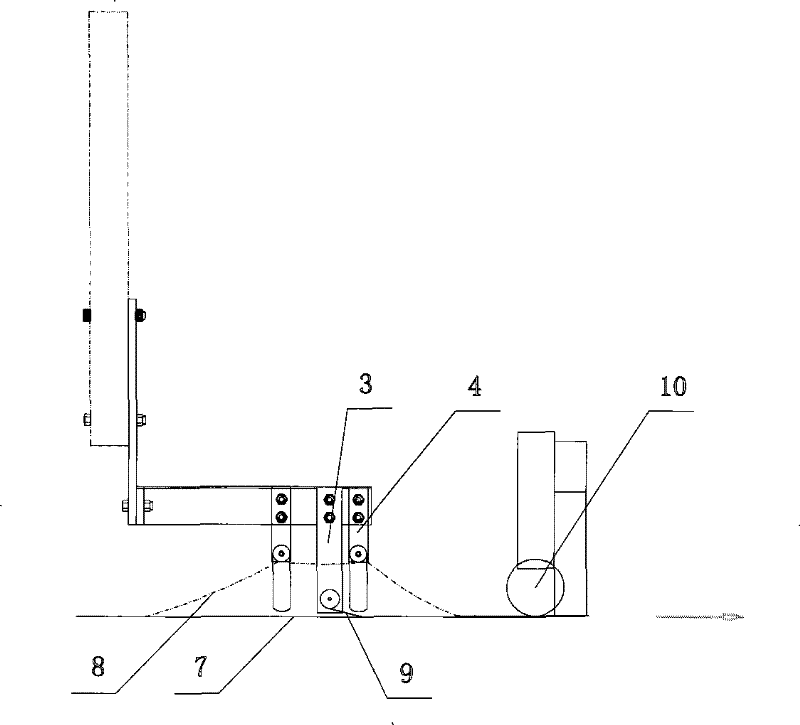

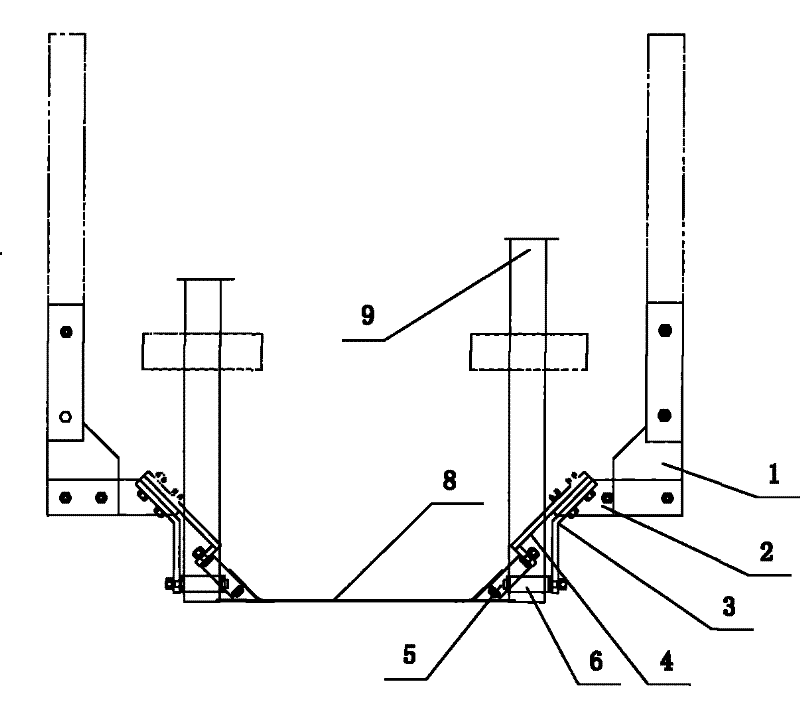

[0037] Example 1, such as figure 1 and figure 2 As shown, the device for laminating the slit film on the reverse side of the inner liner film includes a laminating conveyor belt 7 for conveying the inner liner film 8 and the slit film 9 respectively, and a roller for laminating the two films. Press mechanism 10.

[0038] A flanging guide mechanism is arranged symmetrically along both sides of the airtight layer film 8. The flanging guide mechanism includes left and right mounting brackets 4 and a group of left and right symmetrical flanging rollers 5 connected downwards. An oblique upward angle is formed between the roller 5 and the laminating conveyor belt.

[0039] A horizontal guide mechanism is arranged symmetrically along the left and right sides of the slit films 9, and the horizontal guide mechanism includes left and right guide roller brackets 3, and a group of left and right symmetrical guide rollers 6 connected downwards, and guide rollers 6 Keep parallel with th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap