Traction sliding hydraulic support system

A hydraulic support and traction technology, which is applied to mine roof support, mining equipment, earthwork drilling and other directions, can solve problems such as damage to the connection mechanism, achieve uniform distribution of support force, improve safety and reliability, and compact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

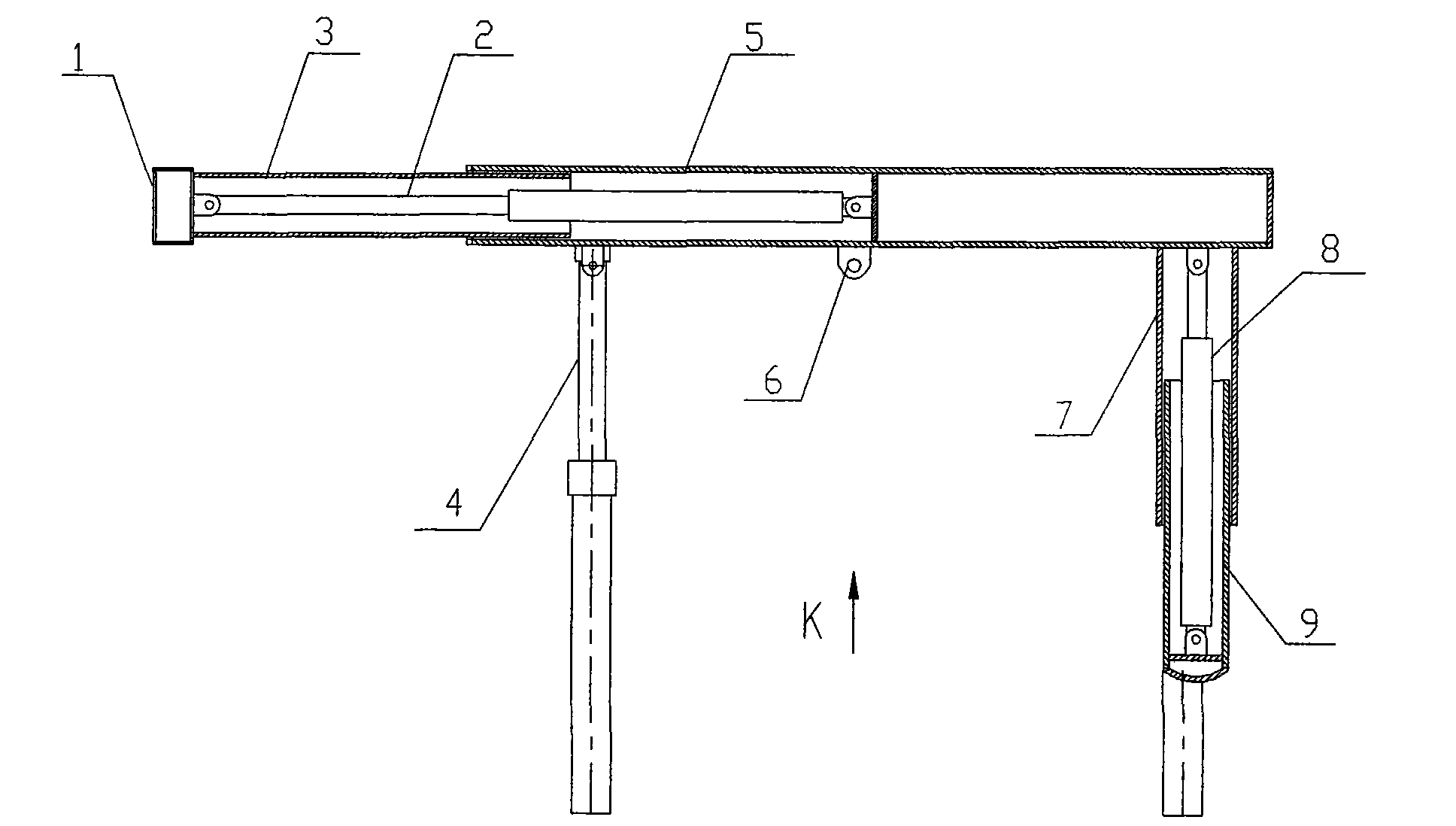

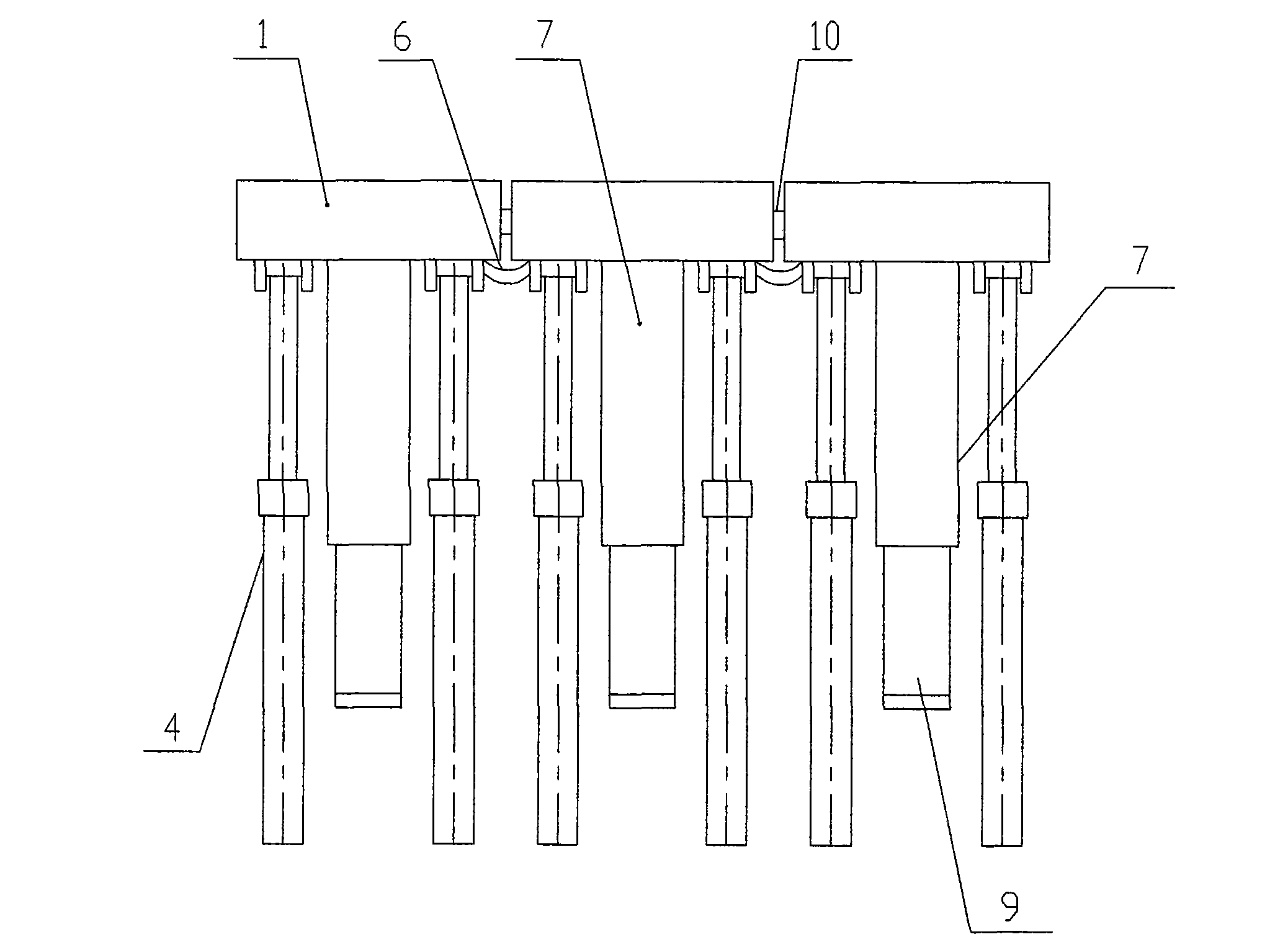

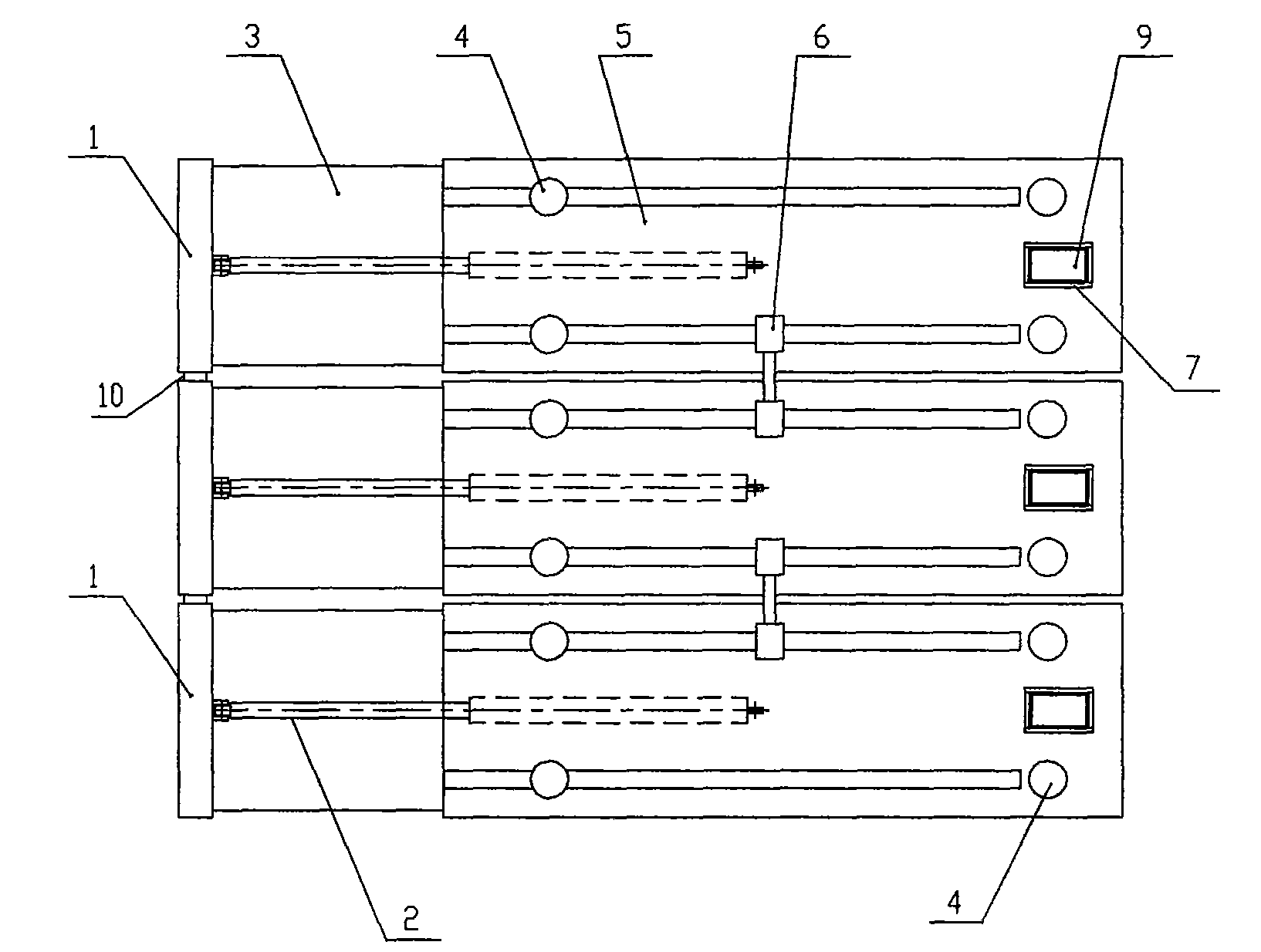

[0017] combine figure 1 , figure 2 and image 3 As shown, the traction sliding hydraulic support system is composed of three traction sliding hydraulic support connections. The traction sliding hydraulic support includes a beam 1, a push jack 2, a guide device 3, a hydraulic prop 4, a top beam 5 and a support system. One end of the guide device 5 is fixed to the beam 1 , and the other end is slidably connected to the top beam 5 . One end of the push jack 2 is connected to the beam 1, and the other end is connected to the top beam 5. When the push jack 2 stretches, the top beam 5 can approach or move away from the cross beam 1 within the range limited by the guide device 5.

[0018] The hydraulic prop 4 is vertically installed on the bottom surface of the top beam 5, and the number of installations is four. It mainly plays the rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com