Test-aiding bracket

A technology of brackets and bosses, applied in the field of fixtures, can solve the problems of incorrect test results, inability to confirm the fixation, poor temperature and vibration limit, etc., to achieve the effect of guaranteeing the test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

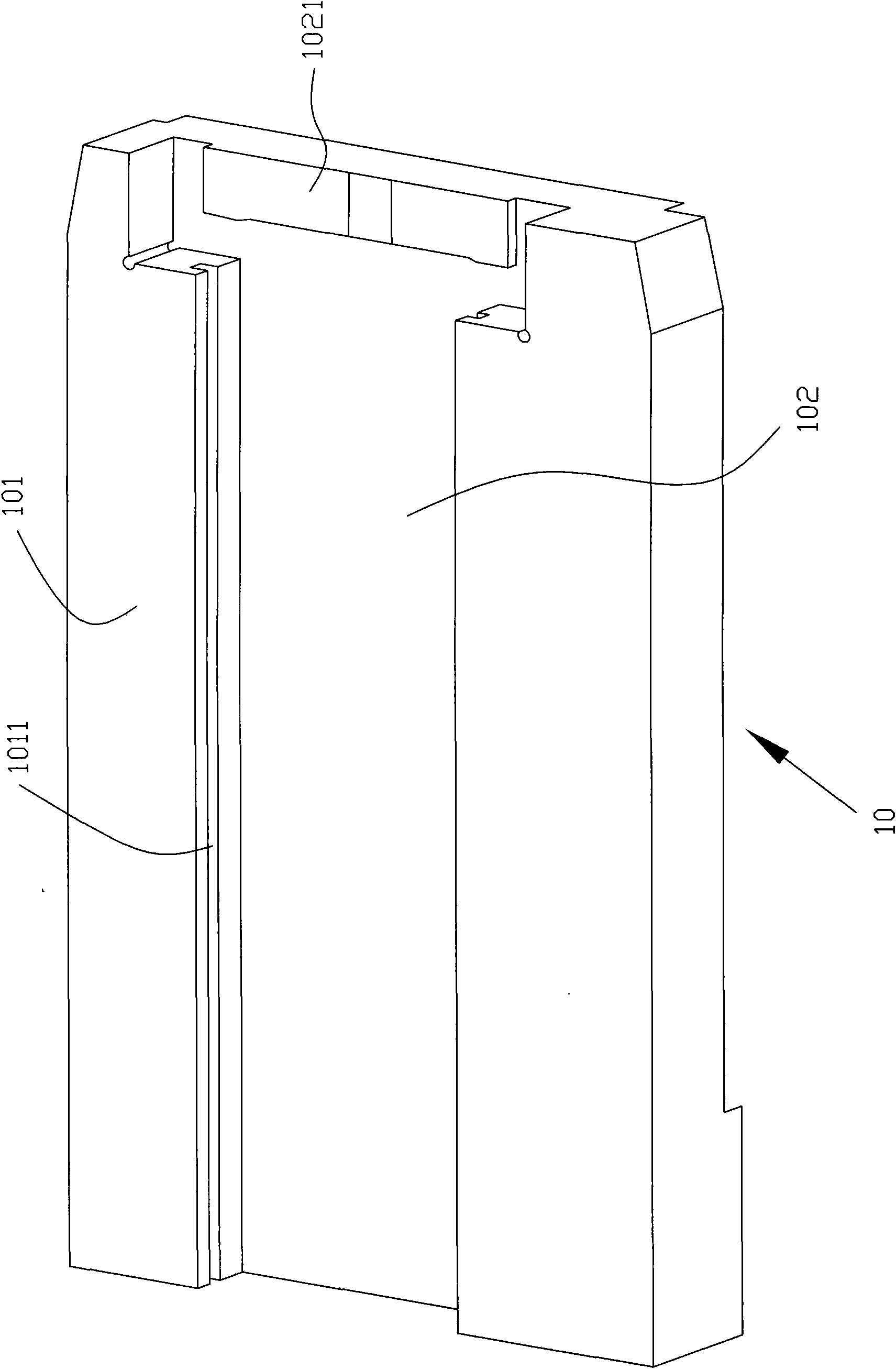

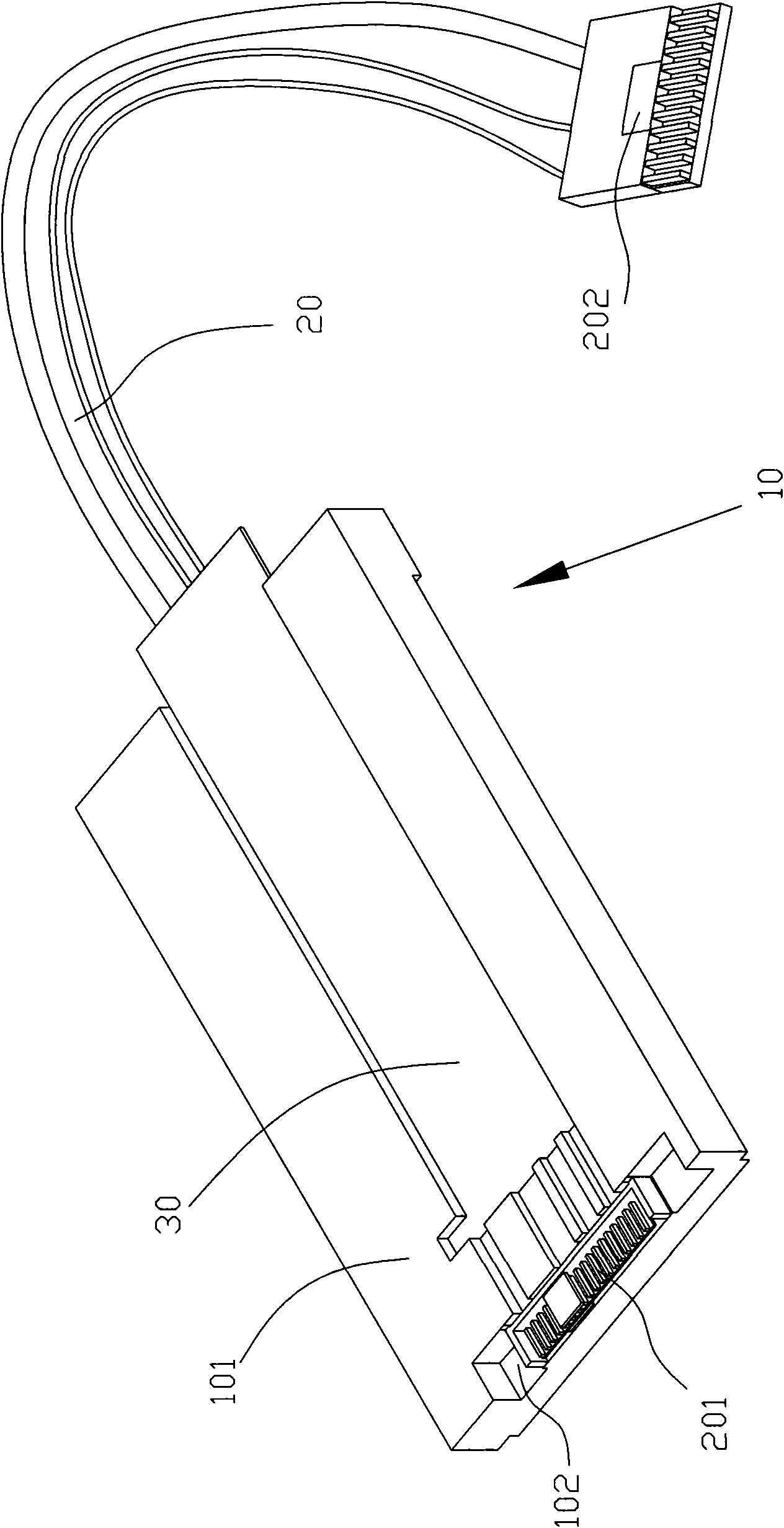

[0009] Please refer to figure 1 and figure 2 shown. The test auxiliary jig 10 described in the present invention is mainly suitable for highly accelerated stress life test (ie, High Accelerated Life Test, HALT), and is used to assist the fixed insertion of the interface at one end of an extension line 20 to a machine to be tested (Fig. On the interface of the motherboard (not shown), the other end interface 202 of the extension cable 20 is connected to a hard disk (not shown in the figure), so that the extension cable 20 is used to move the hard disk outside a constant temperature and humidity box.

[0010] Wherein, the interfaces at the two ends of the extension cord 20 are interface 201 and interface 202 respectively.

[0011] Also, the test auxiliary fixture 10 mainly includes a body 101. In this embodiment, the body 101 is made of bakelite, and its shape and size are similar to those of a hard disk, so that it can be inserted into the machine to be tested instead of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com