High efficiency controllable multiple wheel head magnetic rheology buffing device

A technology of magnetorheological polishing and multiple grinding heads, which is applied in the field of magnetorheological polishing, can solve the problems of not being able to select multiple grinding heads with different hardness at the same time, uneven distribution of magnetorheological fluid, and low polishing efficiency, and achieve simple structure, Ease of operation and improvement of processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

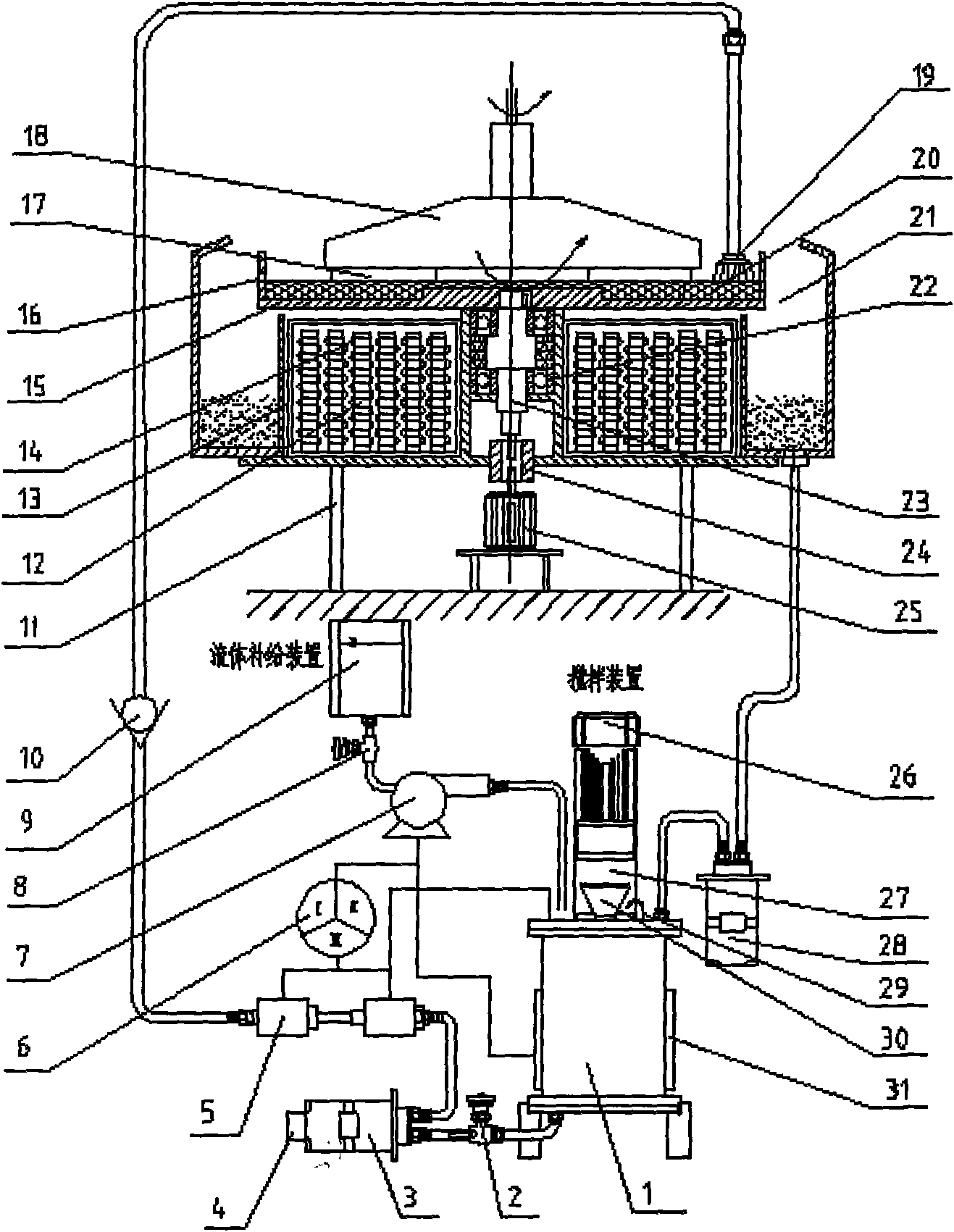

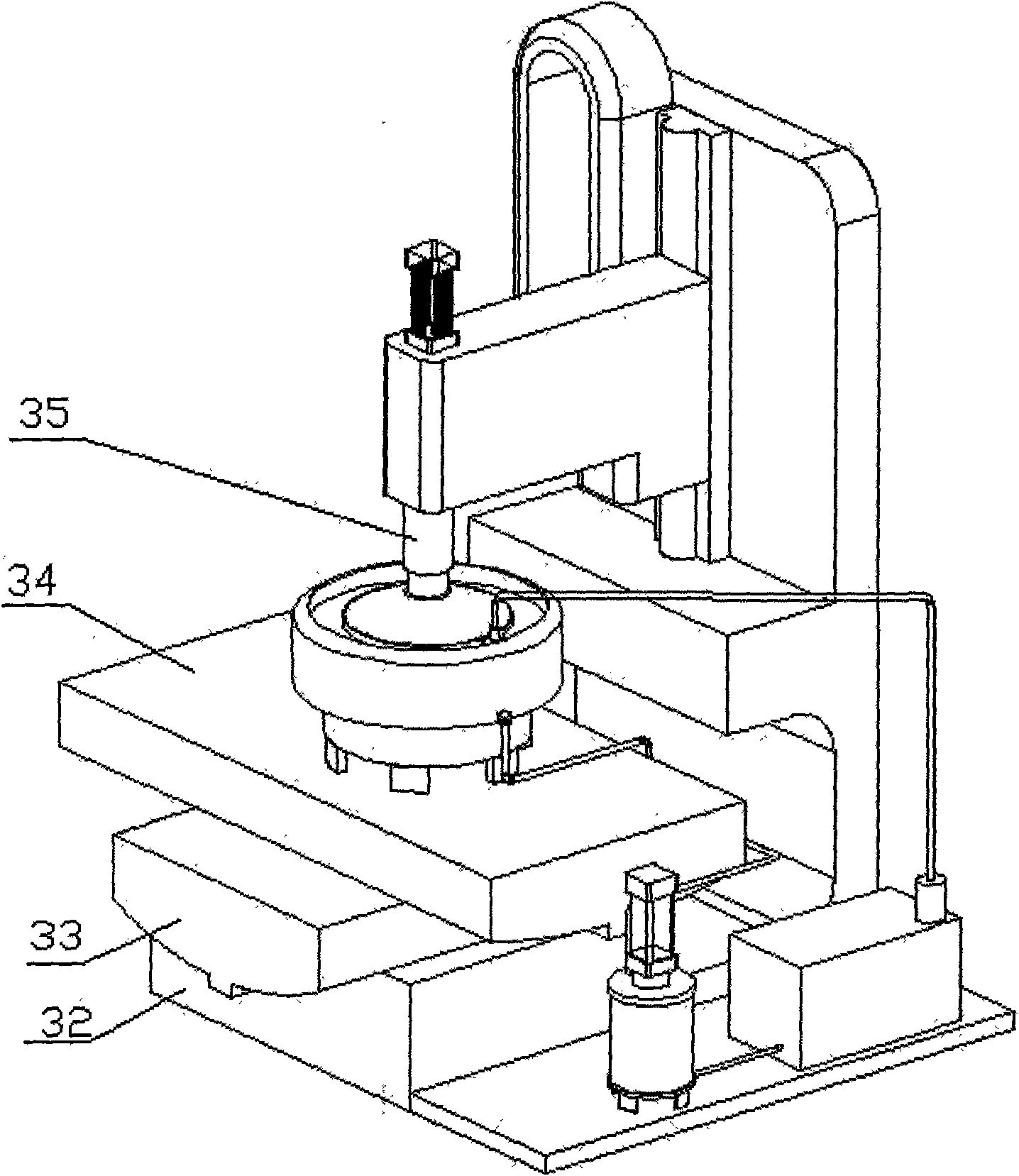

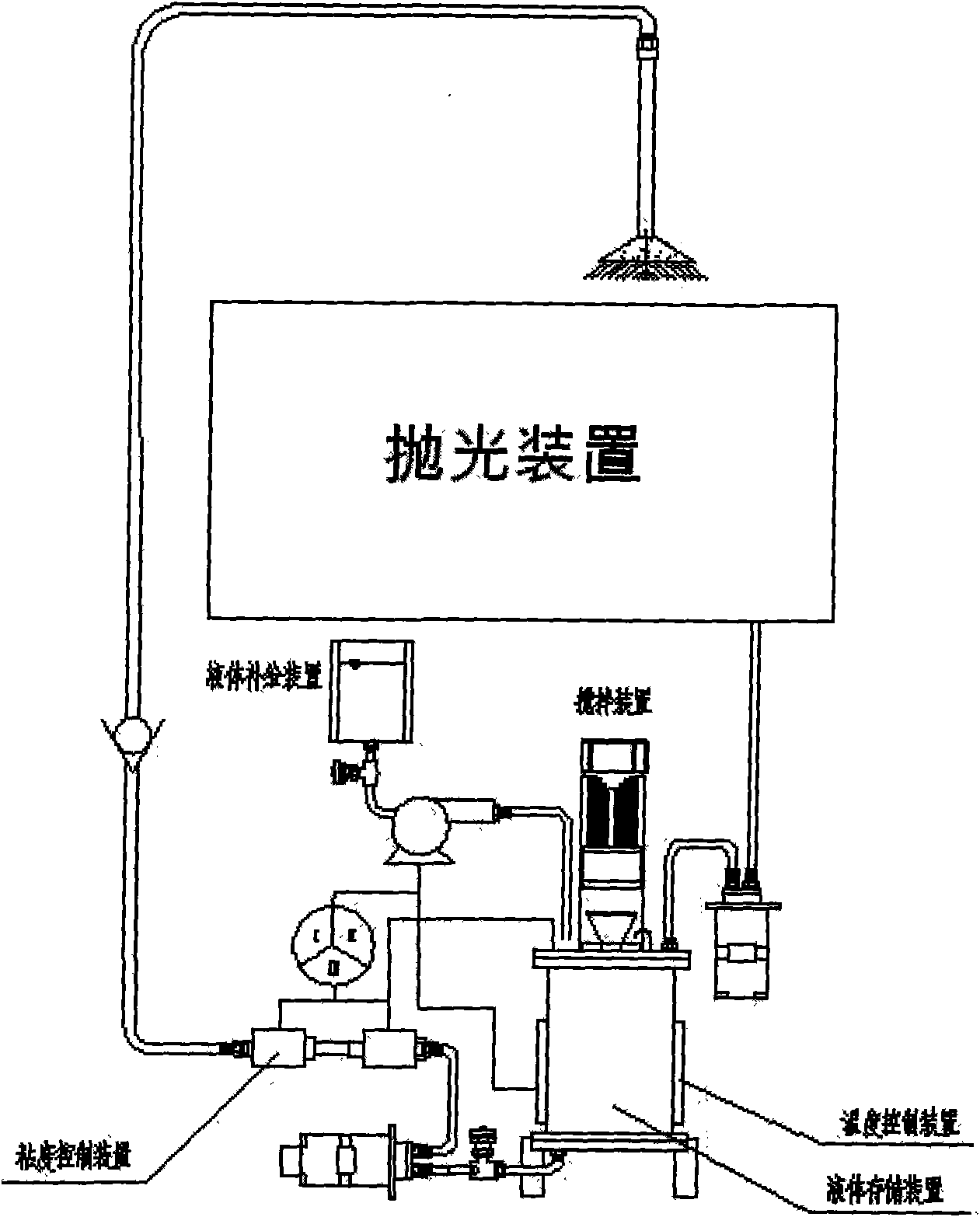

[0043] Example 1, such as figure 1 , figure 2 As shown, the high-efficiency controllable multi-head magnetorheological polishing device is mainly composed of a spindle and its fixture device, a rotary table device, a numerical control platform device, a magnetic field generator and a liquid circulation device. The spindle and its fixture device pass through the machine body and the numerical control platform. Fixed connection, and the workpiece is installed on the polishing spindle through the fixture. The power source drives the spindle to rotate, and its rotation drives the workpiece to rotate. According to the speed requirement, choose whether to increase or decrease the speed. The spindle and its fixture device move along the Z-axis direction to adjust the workpiece and polishing. The relative distance between the pads, while the magnetic field generating device surrounding the polishing pad is fixedly connected to the base, the electromagnetic coil is connected with a c...

Embodiment 2

[0047] Embodiment 2. The overall device and structure of this embodiment are the same as those of Embodiment 1, except that according to the polishing requirements of the workpiece, the magnetic field is distributed in a circular array around the axis in fan-shaped areas. The polishing method and steps of this embodiment are as follows: install the planar optical part on the fixture, position and clamp the optical part; Figure 10 As shown, the rotary device is located directly below the workpiece. Adjust the moving axes of the CNC platform to make the polishing disc reach the initial processing position, and move up and down through the Z-axis of the machine body to adjust the distance between the workpiece and the polishing pad; close the stop valve and turn the magnetic flow The variable liquid is added to the liquid storage cylinder, the shut-off valve is opened and the peristaltic pump is started, the magnetorheological liquid enters the polishing pad through the silicone ...

Embodiment 3

[0048] Embodiment 3. This embodiment has the same overall device and structure as that of Embodiment 1, except that the magnetic field is distributed in multi-ring areas according to the polishing requirements of the workpiece. This embodiment takes the two rings as an example. The polishing method and steps of the implementation are as follows: install two planar optical parts of different sizes or different materials on the fixture, and clamp the optical parts, and respectively position them in the two ring regions. above, such as Figure 12 shown; as Figure 10 As shown, the rotary device is located directly below the workpiece. Adjust the moving axes of the CNC platform to make the polishing disc reach the initial processing position, and move up and down through the Z-axis of the machine body to adjust the distance between the workpiece and the polishing pad; close the stop valve and turn the magnetic flow The variable liquid is added to the liquid storage cylinder, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com