Roll-over protective device of engineering vehicles based on continuous shearing and energy absorption

A technology for engineering vehicles and protection devices, which is applied in the field of continuous shear energy-absorbing and overturning protection devices for engineering vehicles, which can solve the problems of drivers not having enough living space, death, injury, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific content of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

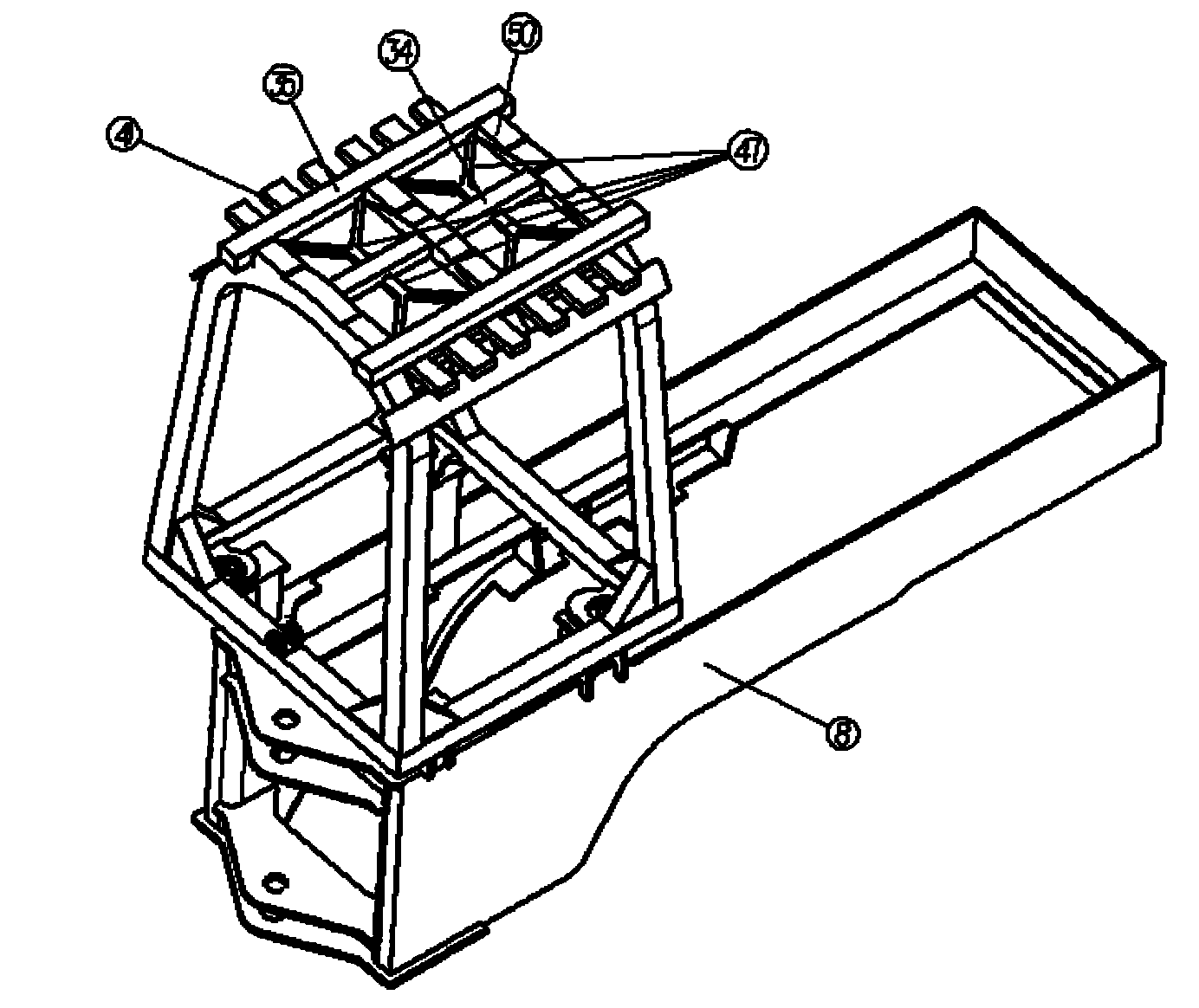

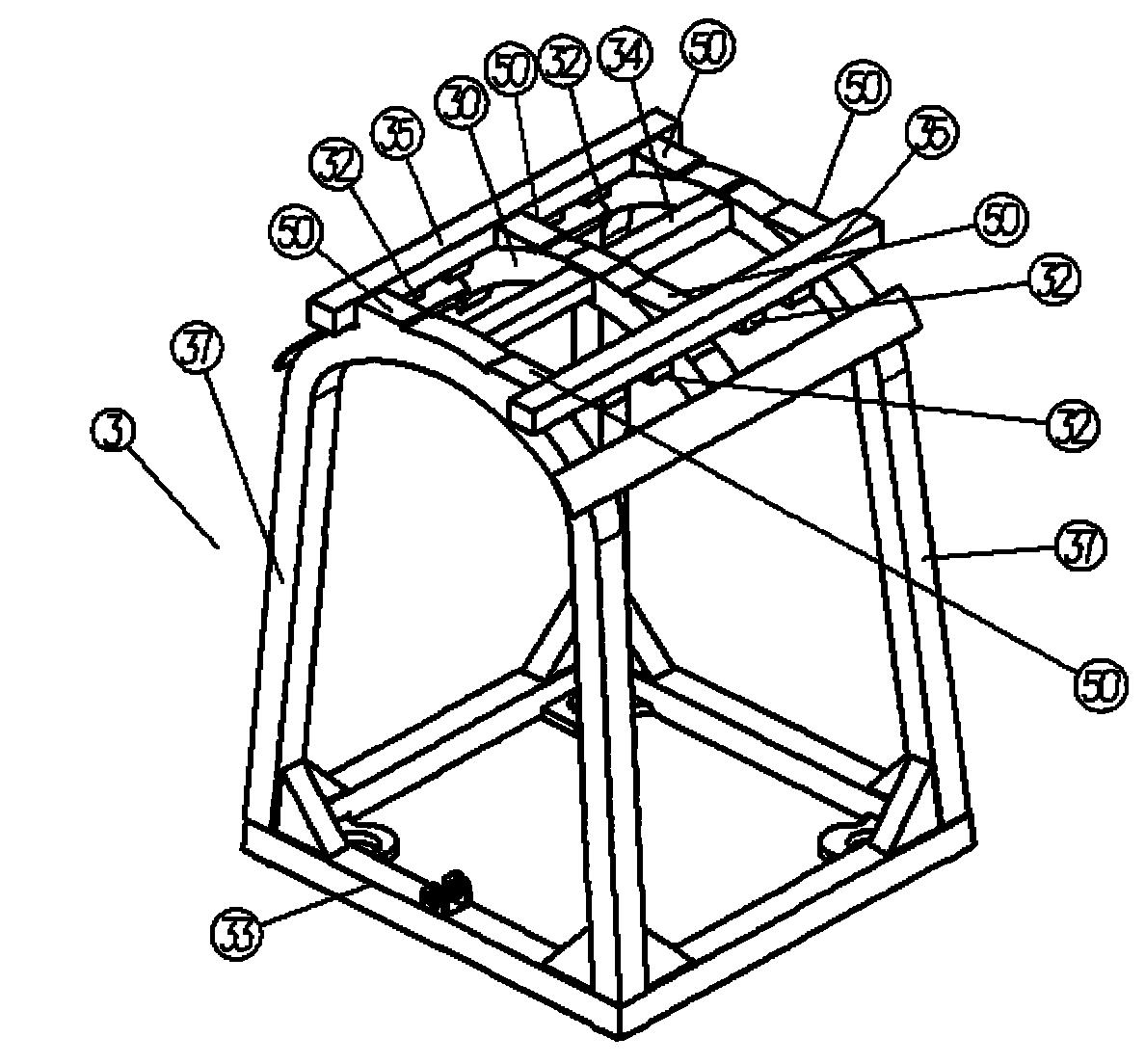

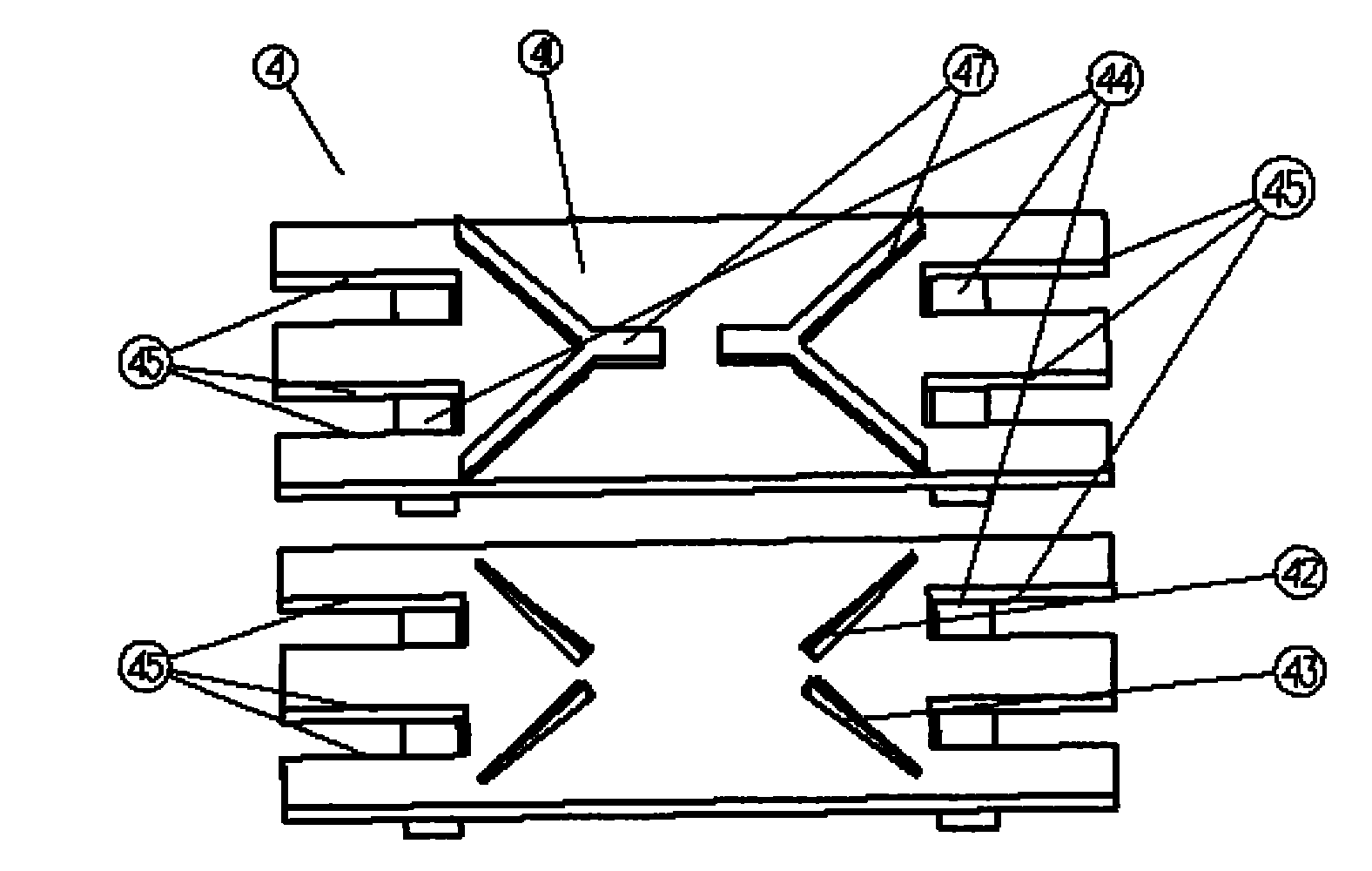

[0028] refer to figure 2 As shown, this embodiment is installed on the rear vehicle frame 8 of the engineering vehicle, and is composed of a steel structure frame 3 and a shear metal energy-absorbing mechanism 4 . refer to figure 2 , 3 , 4, the steel structure frame 3 is made up of base 33, 2 arched vertical frames 37, 1 arched frame 30, 3 connecting beams 34, 2 stressed beams 35. 8 guide sliders 32 are arranged on the underside of 2 stressed beams 35, and 2 arched stands 37 are fixed on the base 33 front and back, and arched stands 30, 3 are arranged between the top surfaces of the 2 arched stands 37. Root connecting beam 34 is left, middle and right distribution and is fixed together with the top surface of 2 arched stands 37 and 1 arched frame 30, the left and right sides of 2 arched stands 37 and 1 arched frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com