Insulator bending-torsion testing machine

A testing machine and insulator technology, applied in the direction of testing material strength by applying stable torsion force, testing material strength by applying stable bending force, etc., can solve the problems of inconvenient data, tedious testing, inaccuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

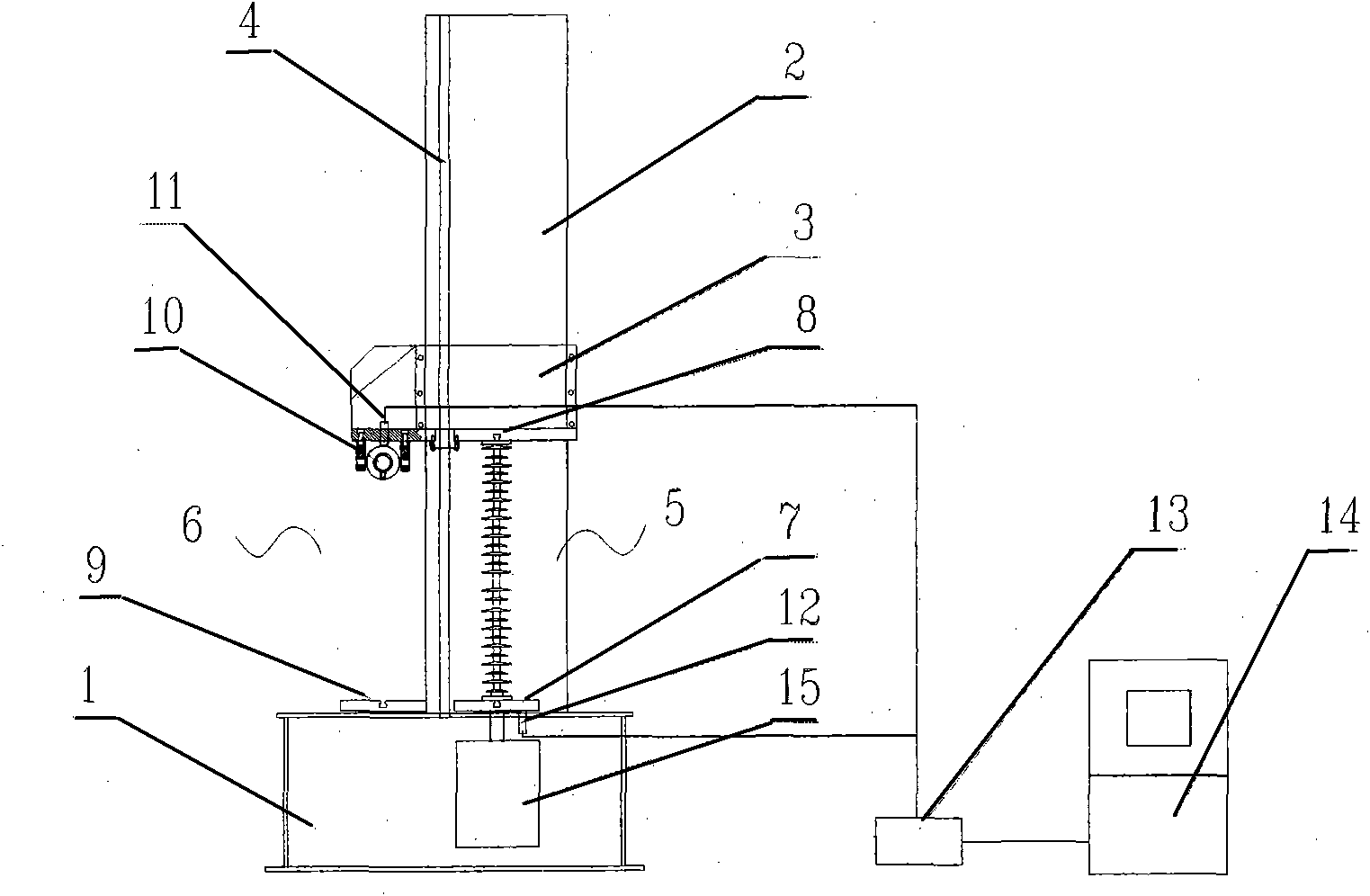

[0009] As shown in the figure, it includes a base 1, a column 2, a slider 3, a lifting screw 4, a bending moment device 6 and a torque device 5, the bending moment device 6 includes the bending moment turntable 9, a hydraulic cylinder 10, and the torque device 5 includes a torque turntable 7, a clamp 8 and a motor 15.

[0010] Above-mentioned base 1 is fixed with upright column 2, and upright screw mandrel 4 is housed on the upright column 2, and slide block 3 is connected on the uplift screw mandrel 4, and slide block 3 can vertically move on upright column 2 by lifting screw mandrel 4. The bending moment turntable 9 of the bending moment device 6 is connected to the base 1 through bearings, the hydraulic cylinder 10 is fixed on the lower end surface of the slider 3, the clamp 8 of the torque device 5 is fixed on the lower end surface of the slider, and the torque turntable 7 falls on the base 1 The end face is connected to the motor 15 through a shaft, and the hydraulic cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com