Basin wrench

A sink and wrench technology, applied in the direction of wrenches, manufacturing tools, wrenches, etc., can solve the problems of limiting the use of known wrenches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

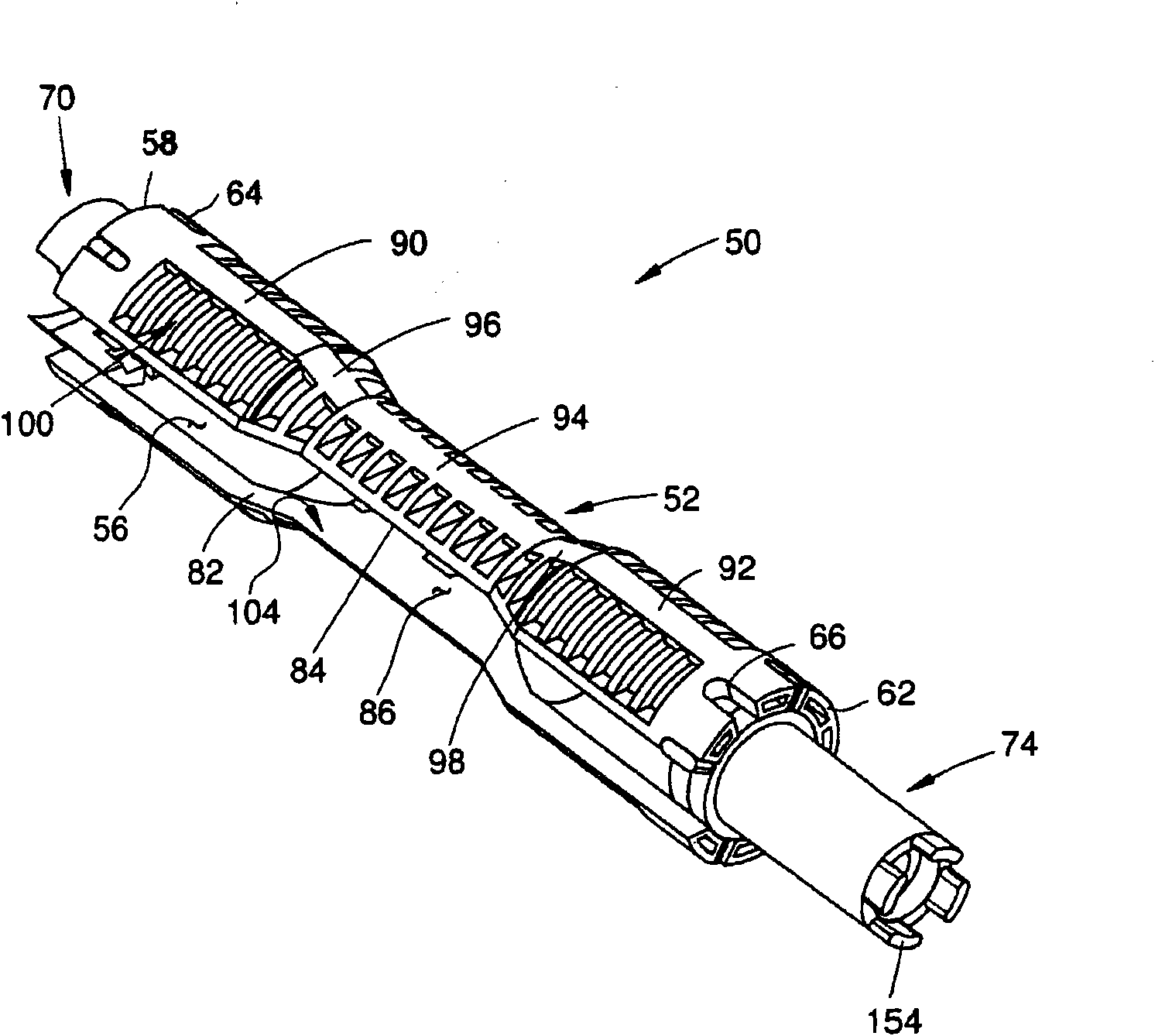

[0025] refer to image 3 , a sink wrench 50 is used to turn sink nuts, such as sink nuts 24 and 26 shown in FIG. 1, to attach the faucet unit to the countertop. The sink wrench 50 is also useful in many other applications such as tightening 7 / 8" supply pipe nuts, plastic wing supply nuts, 1" supply pipe nuts (and nuts with other eg metric sizes) and supply pipe shutoff valves. Accordingly, the present invention should not be limited to a wrench for loosening sink nuts only, but should be broadly interpreted. In the illustrated embodiment, the sink nut 50 is made from a molded rigid plastic material; however, other materials such as metal, composite materials, etc. can also be used.

[0026] according to image 3 In the illustrated embodiment, the sink wrench 50 generally includes an elongated wrench body 52 having a generally hourglass-shaped configuration that is substantially axially symmetrical about a longitudinal axis 54 ( Figure 4 ), the longitudinal axis 54 is also th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap