Winch band shaft

A technology with shaft and winch, applied in the field of winch with shaft and winch, can solve the problems of poor applicability of winch, inability to apply binding belt, etc., and achieve the effect of high applicability and high practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

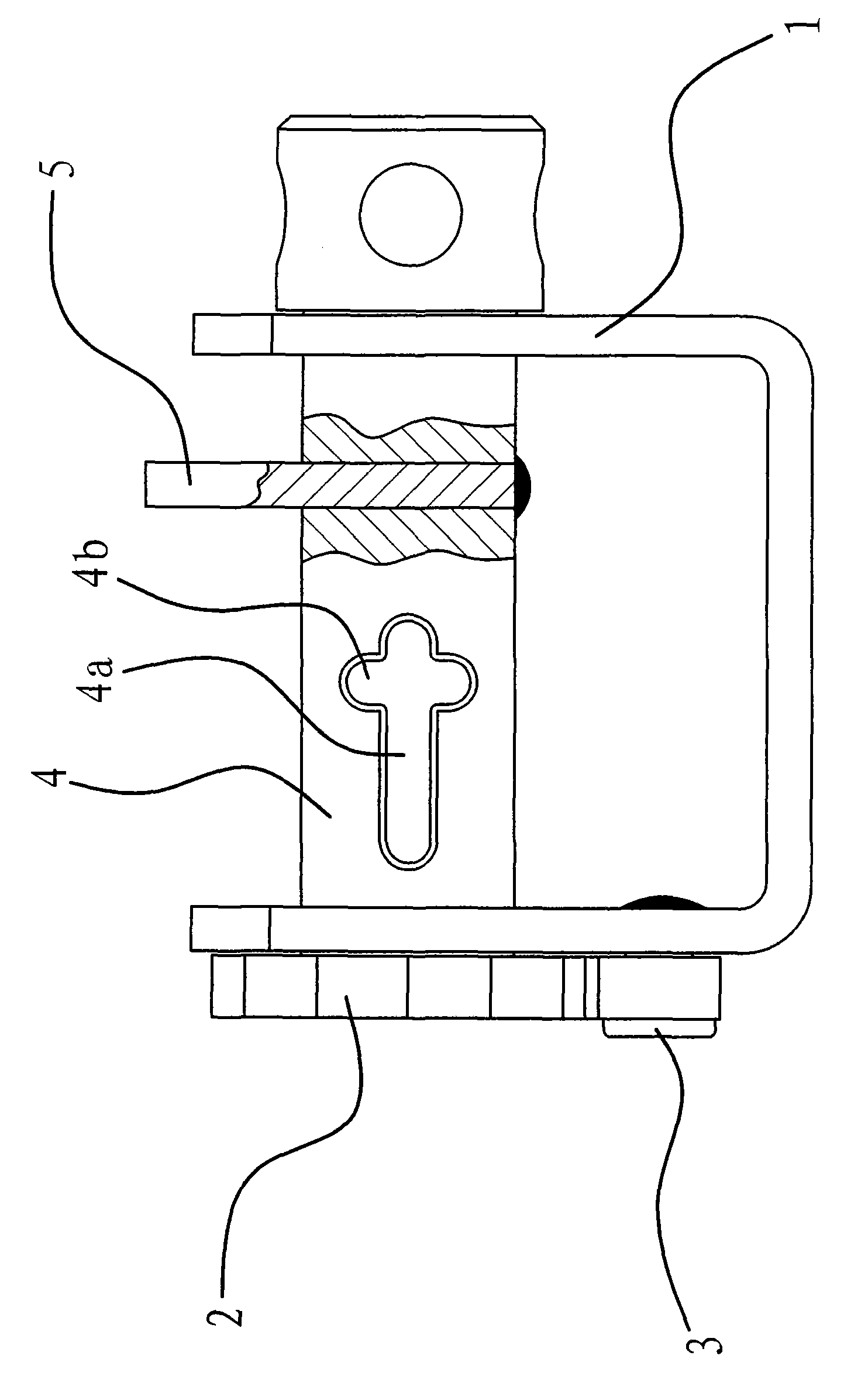

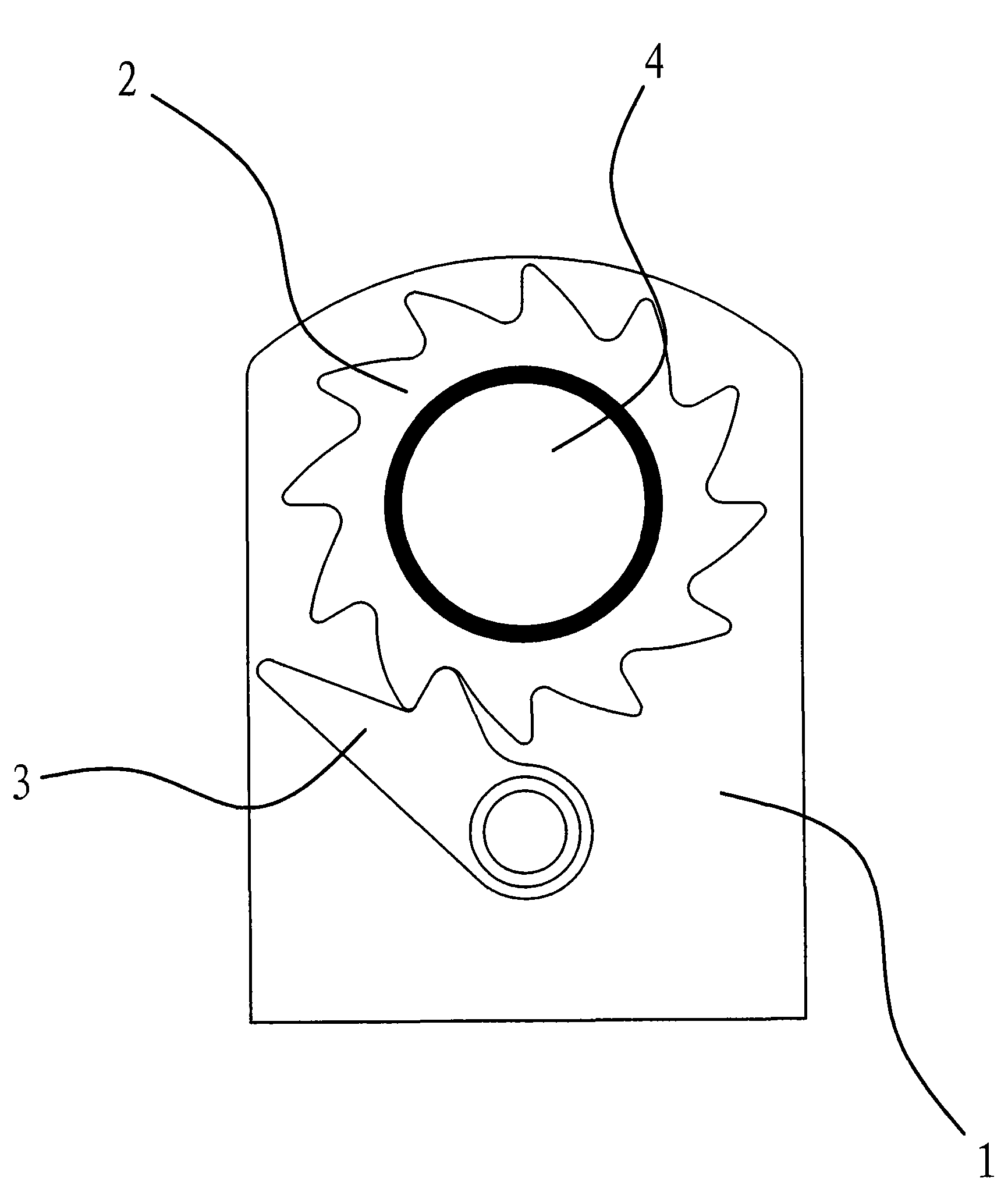

[0022] Such as figure 1 and figure 2 As shown, the winch includes a bracket 1 and a belt shaft connected to the bracket 1, the belt shaft can rotate relative to the bracket 1, and a unidirectional mechanism is provided between the bracket 1 and the belt shaft so that the belt shaft can only rotate in one direction.

[0023] The one-way mechanism is the ratchet 2 fixed on the belt shaft and the ratchet 3 hinged on the bracket 1. There is a spring between the ratchet 3 and the bracket 1. Under the elastic force of the spring, the ratchet 3 is embedded in the phase of the ratchet 2. between two adjacent ratchets.

[0024] The winch belt shaft includes a rod-shaped body 4, the body 4 has a through hole 4a, the through hole 4a runs through the body 4 radially and it is strip-shaped along the body 4 axial direction.

[0025] The main body 4 also has a second through hole 4b, which runs through the main body 4 radially and is strip-shaped along the radial direction of the main bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com