Constant-flow bubble type automatic water level measurement method

An automatic measurement, bubble technology, applied in the field of sensor measurement, can solve problems such as large errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

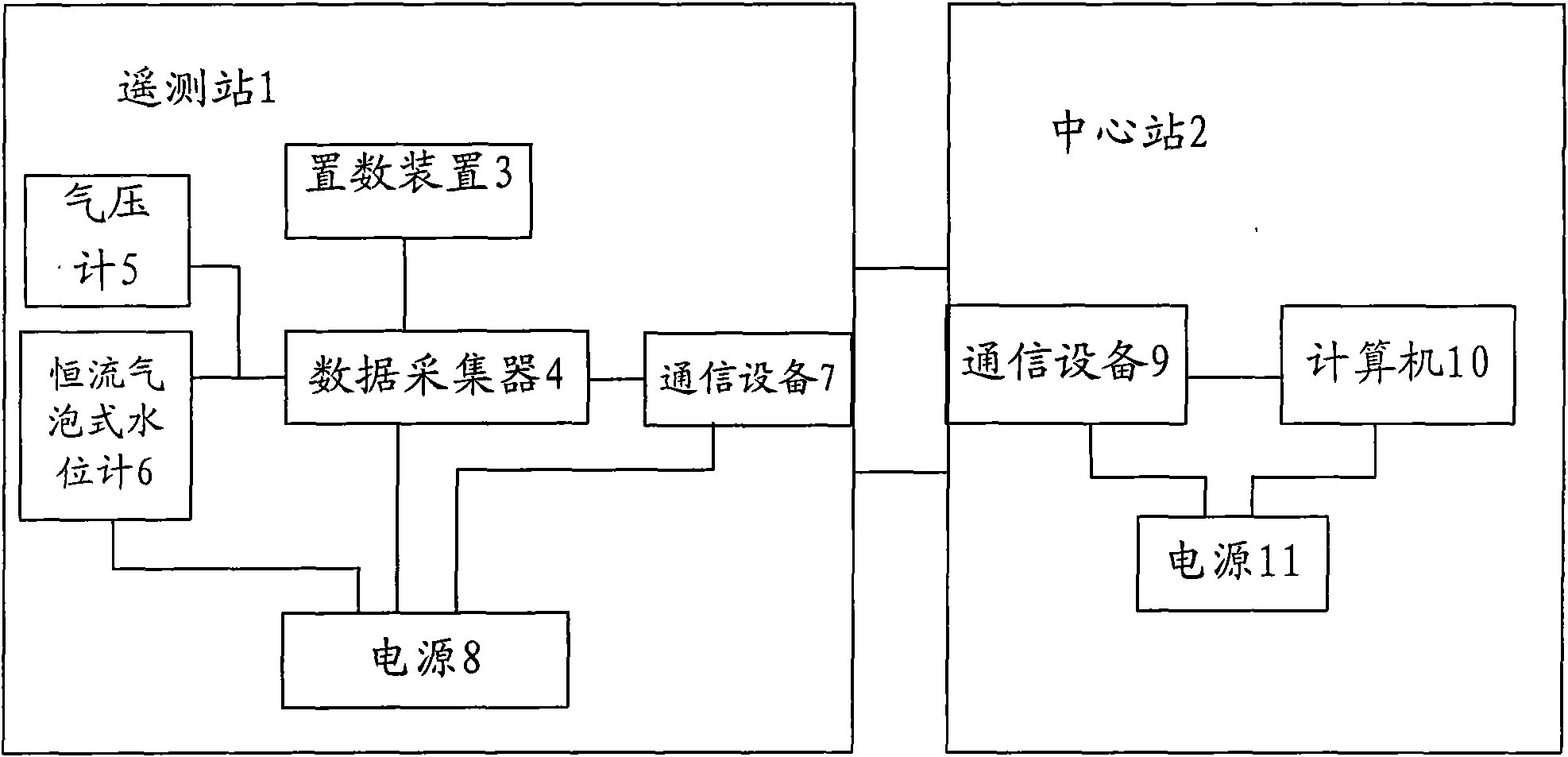

[0018] Water level automatic measuring method of the present invention comprises telemetry station 1 and central station 2, as figure 1 shown. The telemetry station is composed of a number setting device 3 , a data collector 4 , a barometer 5 , a constant-flow bubble water level gauge 6 , a communication device 7 and a power supply 8 . The central station consists of a communication device 9, a computer 10 and a power supply 11.

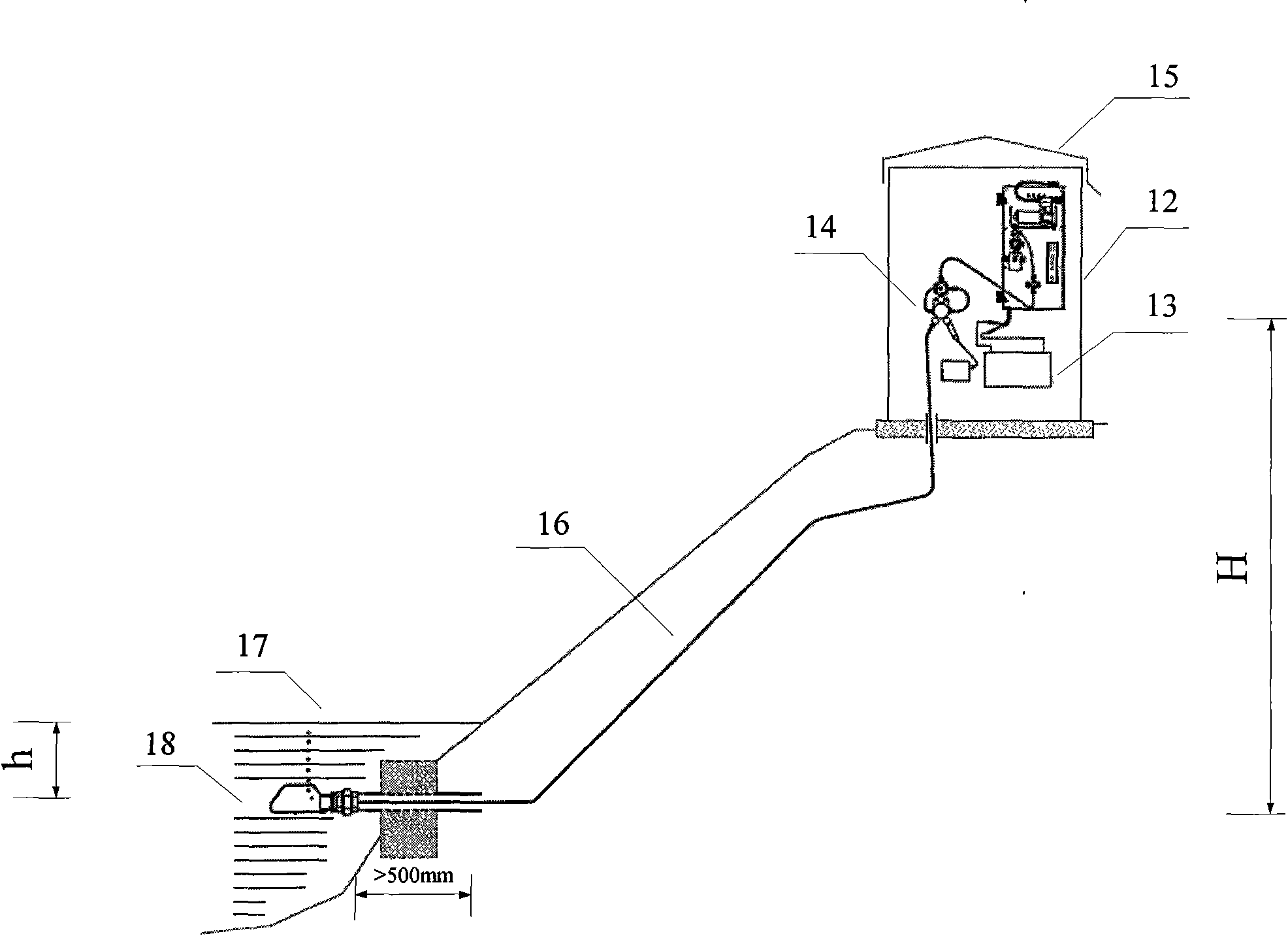

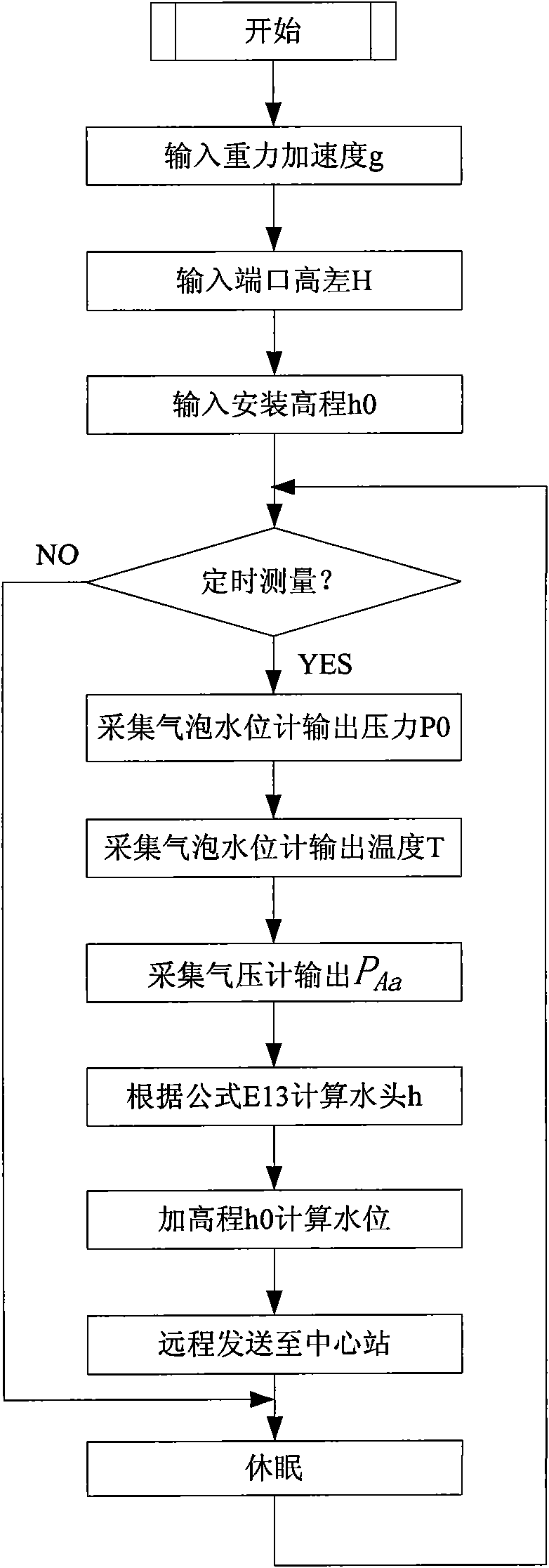

[0019] The water level measurement process is as follows: image 3 shown. The data collector regularly collects the pressure output value P of the constant-flow bubble water level gauge according to the preset working mode. 0 and the gas temperature T in the tube, and the pressure output value P of the barometer Aa , calculate the water head height according to the formula (E13), correct the actual water level according to the height, and send the water level data to the central station through the communication terminal for display, storage and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com