Method for determining duty ratio of universal pulse width controlled by three-phase AD motor PWM

A determination method, three-phase AC technology, applied in AC motor control, motor generator control, electronic commutation motor control, etc., can solve problems such as higher requirements for processor computing power, large amount of programming code, and large amount of calculation. , to achieve the effect of improving operation speed, high-precision SVPWM control, and improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

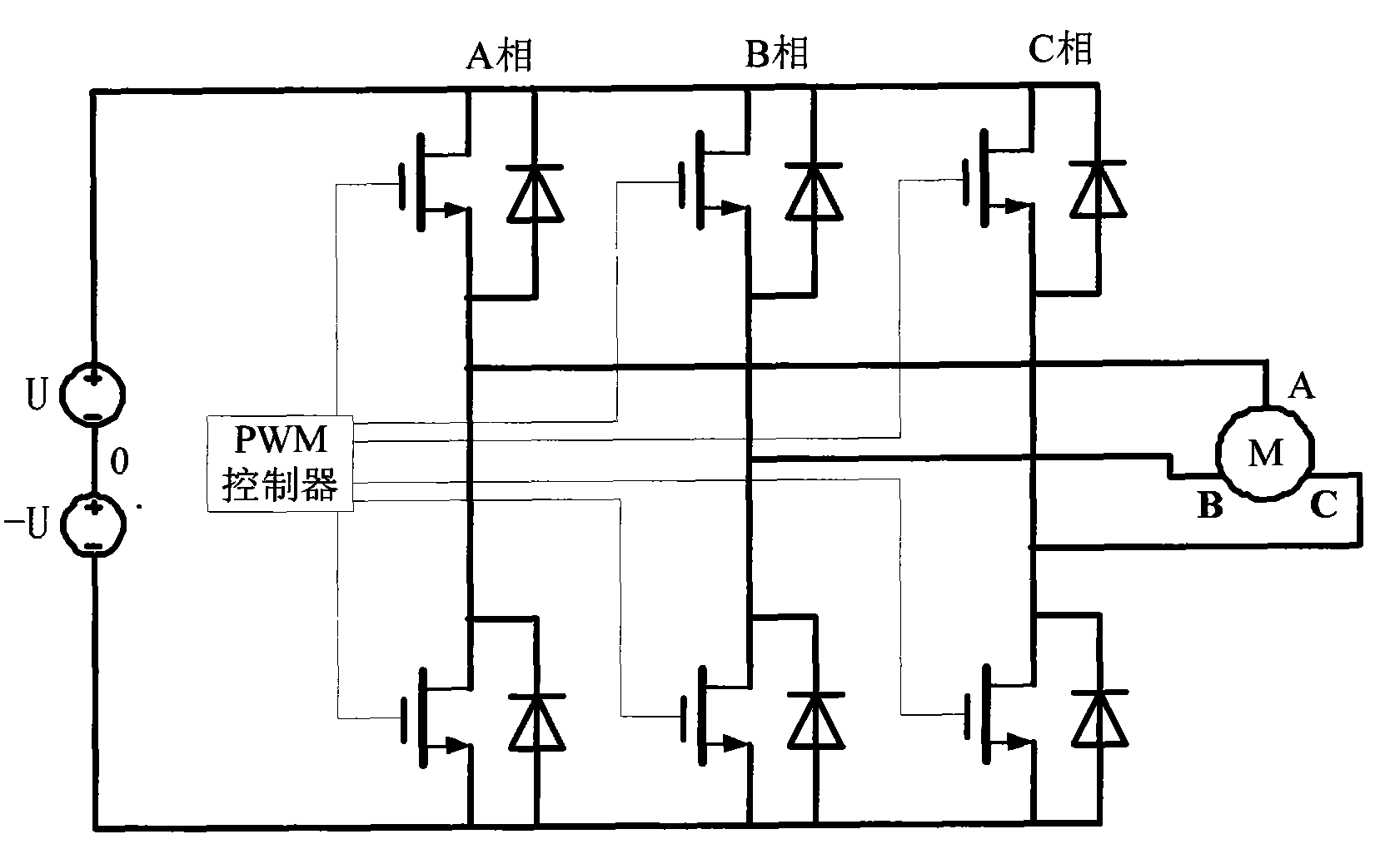

[0038] Before introducing the embodiments of the present invention, first introduce the concept of the present invention.

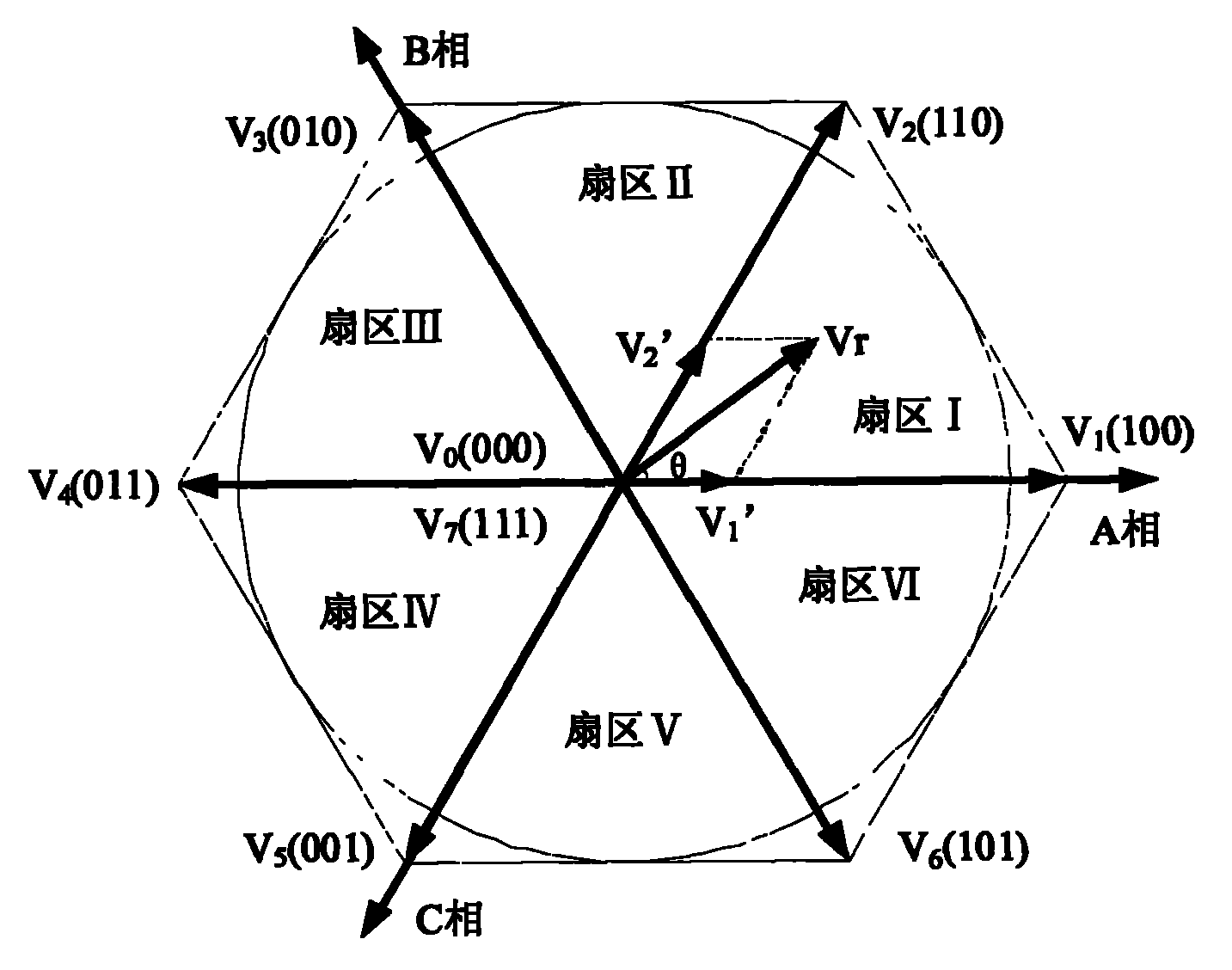

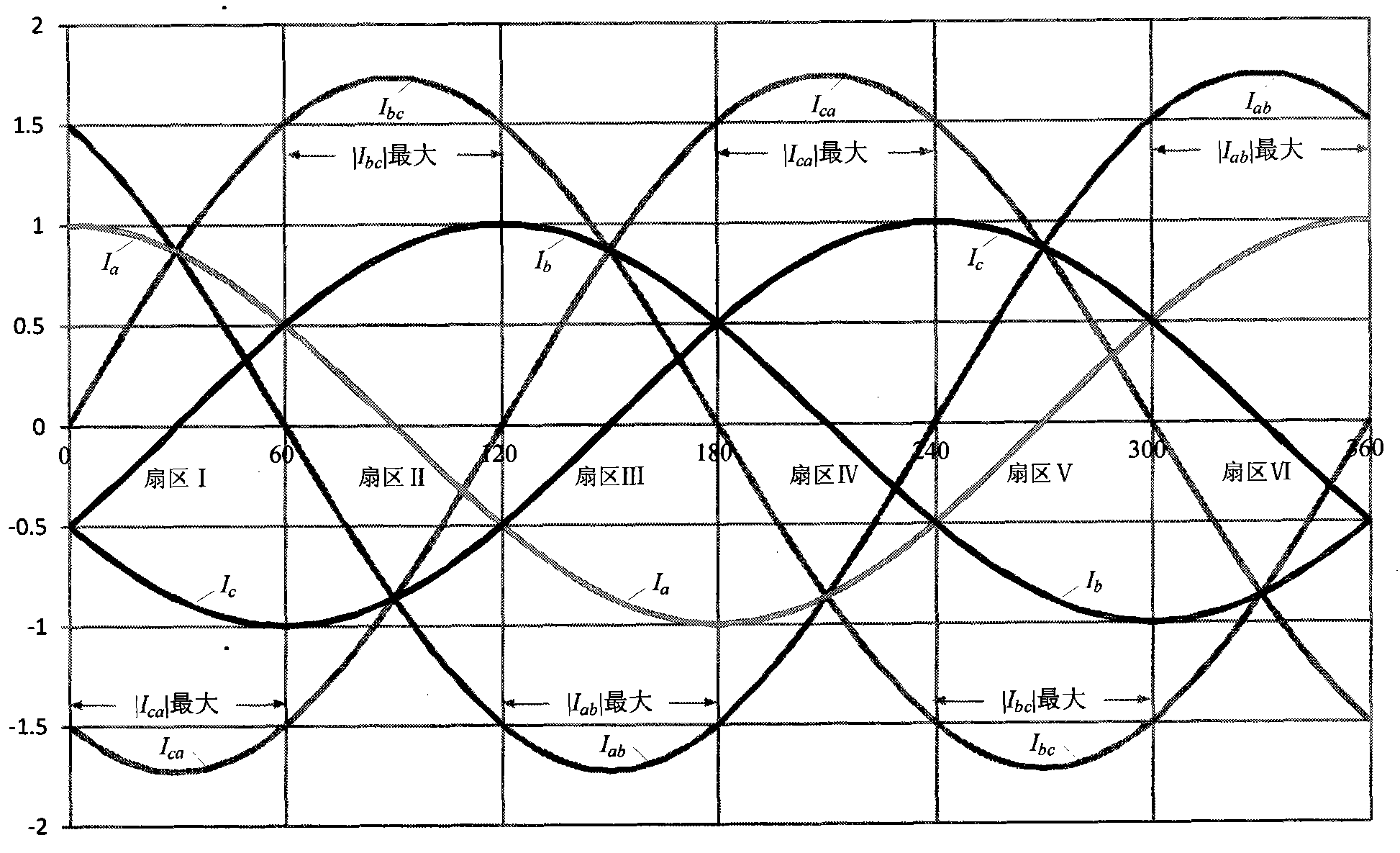

[0039] The purpose of the present invention is to directly determine the three-phase duty cycle based on known three-phase current values, avoiding complex sector judgment and space vector decomposition. From image 3It can be seen that if the three-phase AC motor stator current I a , I b , I c A change cycle of 0°~60°, 60°~120°, 120°~180°, 180°~240°, 240°~300° and 300°~360° are divided into 6 phase angle intervals. The 6 phase angle intervals correspond to figure 2 Sector I, Sector II, Sector III, Sector IV, Sector V, and Sector VI of the space vector shown.

[0040] First, every two-phase current difference I of the three-phase current ab , I bc , I ca Although the changes in these 6 phase angle intervals are different, the maximum value of its absolute value max{|I ab |,|I bc |,|I ca |} changes with regularity, that is,

[0041] In the pha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com