Electropneumatic valve

A pneumatic valve and electric technology, applied in the direction of non-electric variable control, fluid pressure actuator, servo motor assembly, etc., can solve the problem that the pneumatic amplifier does not directly follow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

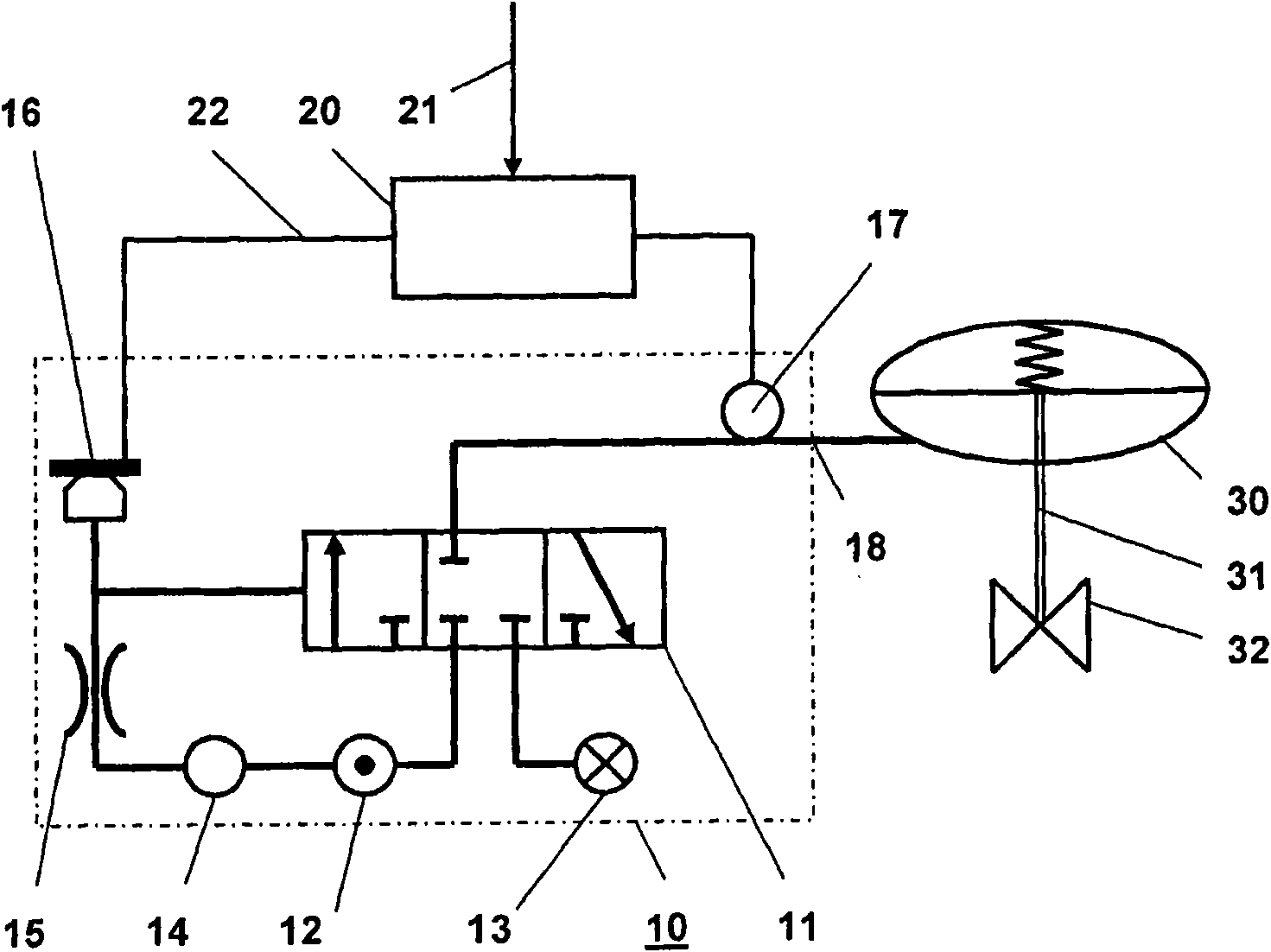

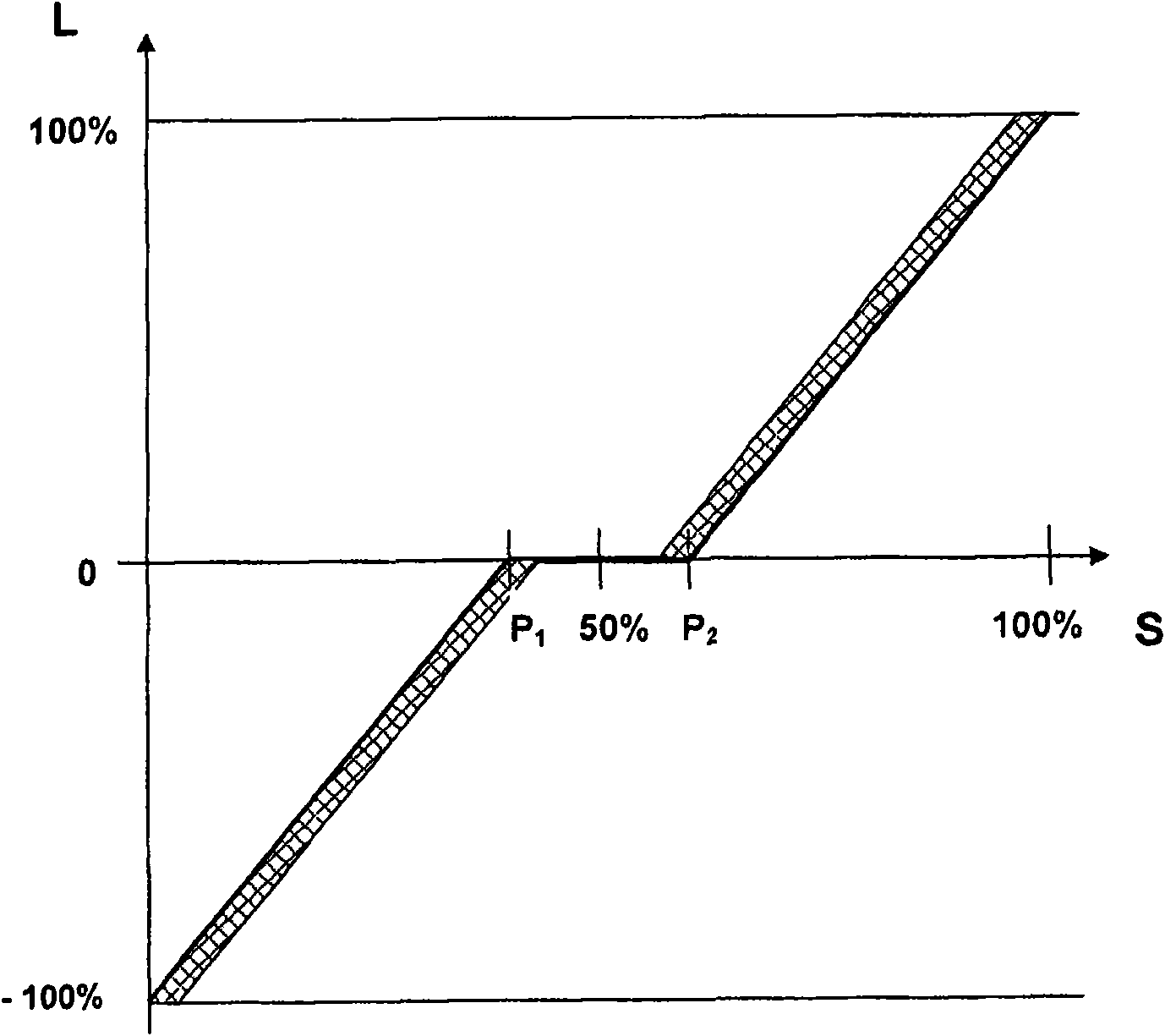

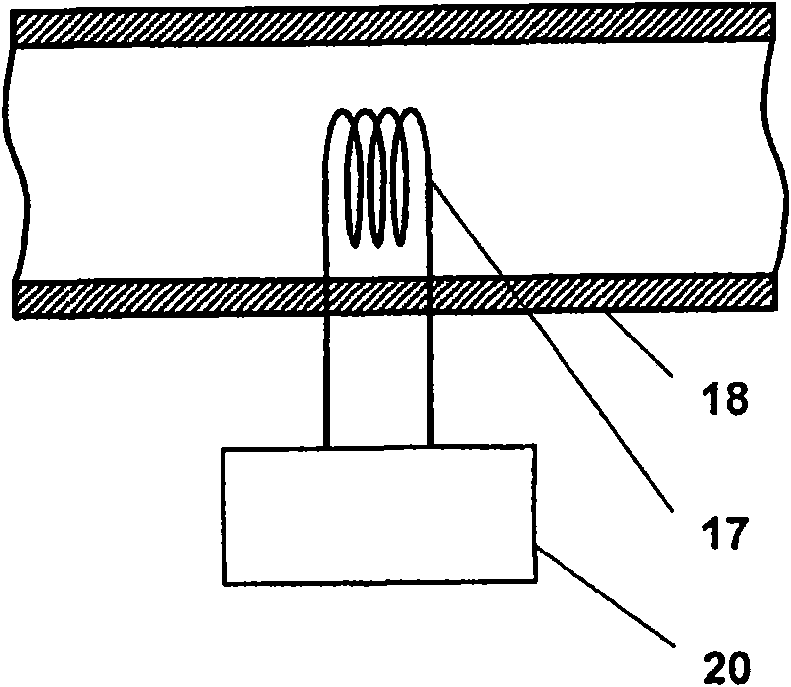

[0031] figure 1 Shown is an electropneumatic valve 10 for controlling a single-acting pneumatically adjustable drive 30 with an electropneumatic transducer 16 and a pneumatic amplifier with a valve device 11 for selectively switching the The connecting channel 18 of the actuating drive 30 is connected to the supply air channel 12 or to the exhaust air channel 13 . The valve device 11 is preferably designed as a 3 / 3-way valve 11 with a sealing medium position.

[0032]The 3 / 3-way valve 11 with a sealing medium position is designed to selectively connect the connecting channel 18 to the actuating drive 30 with the supply air channel 12 or with the exhaust air channel 13 . The prescribed actuation of the 3 / 3-way valve 11 with the sealing medium position takes place by the electropneumatic transducer 16 as a function of the electrical control signal 22 . For this purpose, an electropneumatic transducer 16 is connected via a pressure regulator 14 and a throttle 15 to the supply a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com