Floating bush used for inspecting mechanical parts

A technology of floating bushings and mechanical parts, applied in the production field of inspection accessories, can solve the problems of scrapping, unfavorable industrial rapid development, waste of manpower, material resources and time, etc., and achieve the effect of accurate quality inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the drawings:

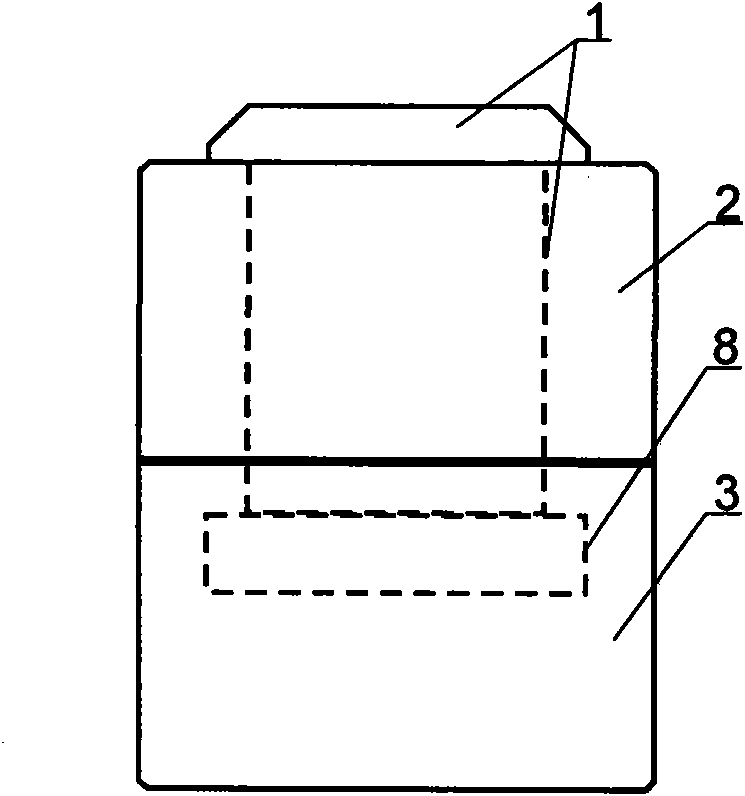

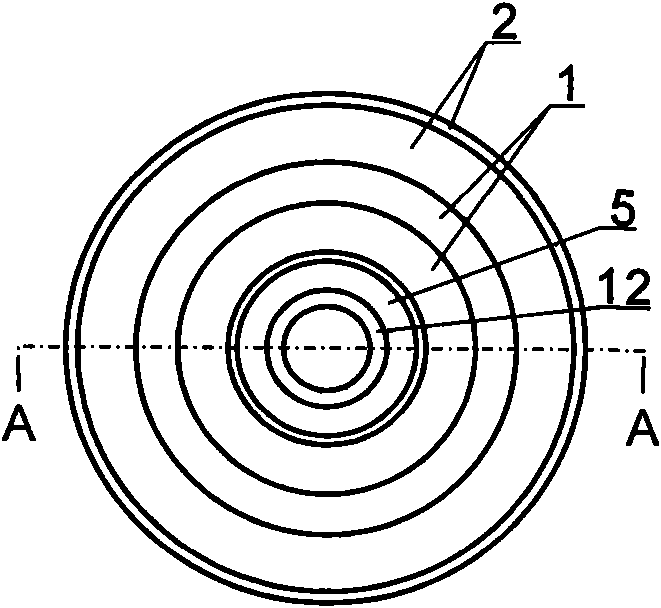

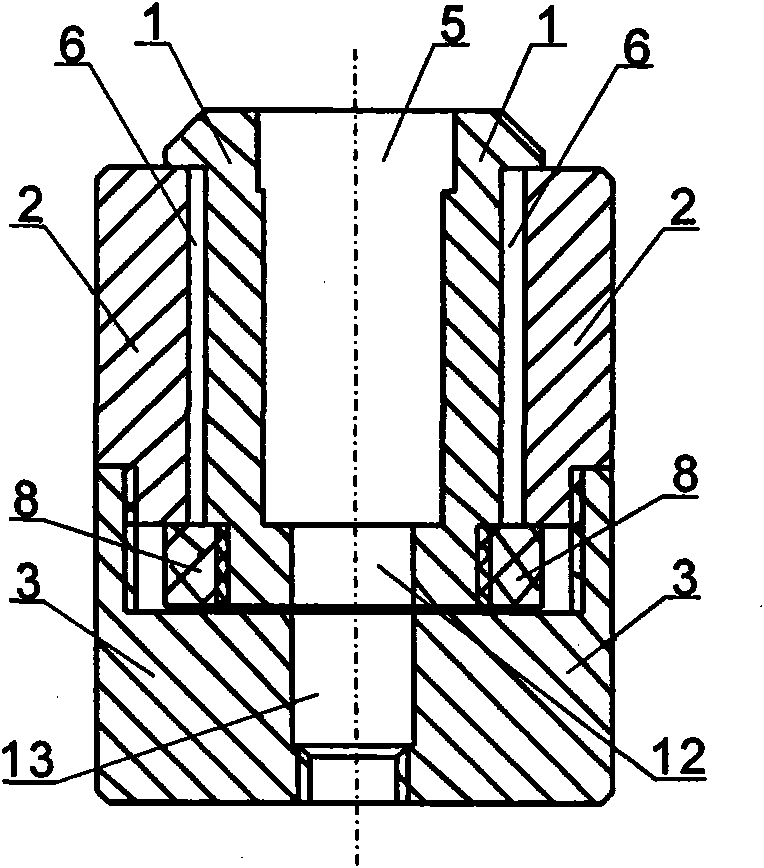

[0017] Such as figure 1 , figure 2 with image 3 As shown, the present invention is composed of a fixed sleeve seat 3, a fixed sleeve 2, a movable sleeve 1 and a movable sleeve fixing ring 8. The fixed sleeve seat 3, the fixed sleeve 2 and the movable sleeve 1 are all hollow cylinders. figure 2 with image 3 It can be seen that the axis of the fixed sleeve seat 3 and the fixed sleeve 2 are united, and the axis of the moving sleeve 1 is united or parallel to the axis of the fixed sleeve 2 (the axis is united as shown in the figure, but because the moving sleeve 1 can move to deviate from the axis of the fixed sleeve 2, so the axis may be parallel). Combine figure 1 , figure 2 with image 3 , Taking the vertical direction as the axis direction of the fixed sleeve seat 3 and the fixed sleeve 2, the upper end of the movable sleeve 1 expands outwards and its radius is greater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com