Automatic detection system for transparent bottle

An automatic detection and lighting system technology, applied in the field of detection systems, can solve the problems of complex computing process, low imaging resolution, small shooting range, etc., and achieve the effect of high light concentration, high brightness and saving installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

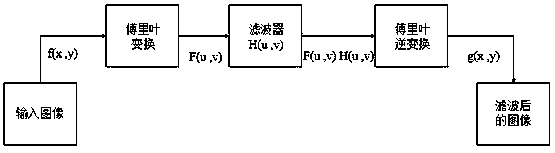

Method used

Image

Examples

Embodiment 1

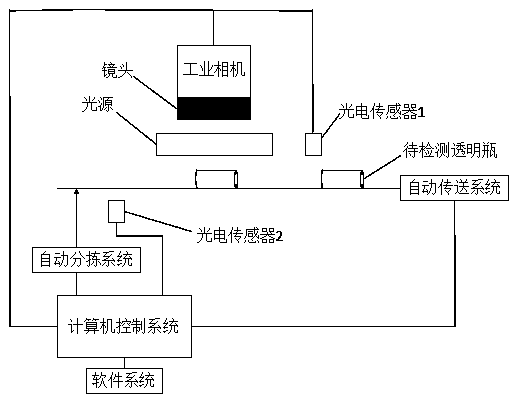

[0025] An automatic detection system for transparent bottles, specifically comprising the following:

[0026] Optical lighting system: including a light source and a light source controller, providing uniform and stable lighting for the image acquisition system, making the surface features of the transparent bottle to be tested visible; the light source is a ring light source, providing different angles of illumination, highlighting the three-dimensional information of the transparent bottle, and solving Diagonally illuminated shadowing issues.

[0027] Image acquisition system: including industrial cameras, lenses and image acquisition cards, which mainly collect images on the surface of transparent bottles, and output video signals from the system unit for processing by the image processing unit; industrial cameras are CCD cameras, which convert optical images into corresponding Digital signal, and the digital signal is transmitted from the interface between the industrial c...

Embodiment 2-11

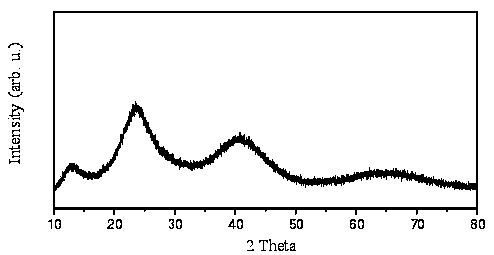

[0035] In the image acquisition system, since the lens is the starting point for the information collection and transmission of the measured object in the entire visual system, its quality directly affects the accuracy of the measured transparent bottle information contained in the final image. The lens is an important part of the lens. Its performance directly affects the quality of the lens. In order to form the optical image of the target on the surface of the CCD sensor, the CCD camera can collect clear and sharp images, reduce the degree of dispersion, improve the resolution of the imaging and its Quality, the used lens of the present invention is made of 6 lenses, and the first three lenses are Ge 20 Sb 15 Se 65 Glass, zinc selenide and zinc sulfide, the focal power is negative, positive and positive respectively, and the last three lenses are zinc selenide, zinc sulfide and Ge 20 Sb 15 Se 65 Glass, its focal power is negative, negative, positive, respectively, where...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com