A solar built-in reflector and its design method

A reflector, built-in technology, applied in the field of solar energy utilization, can solve problems such as the temperature rise of the reflector, damage to the heat absorbing body film layer, and reduce the practical effect, so as to reduce the processing difficulty, avoid the waste of light energy, and prolong the service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

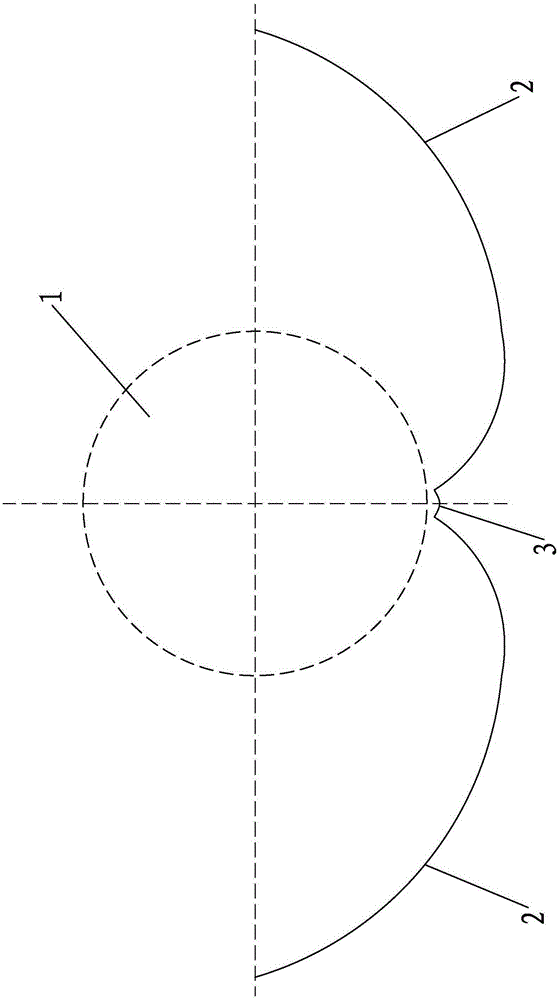

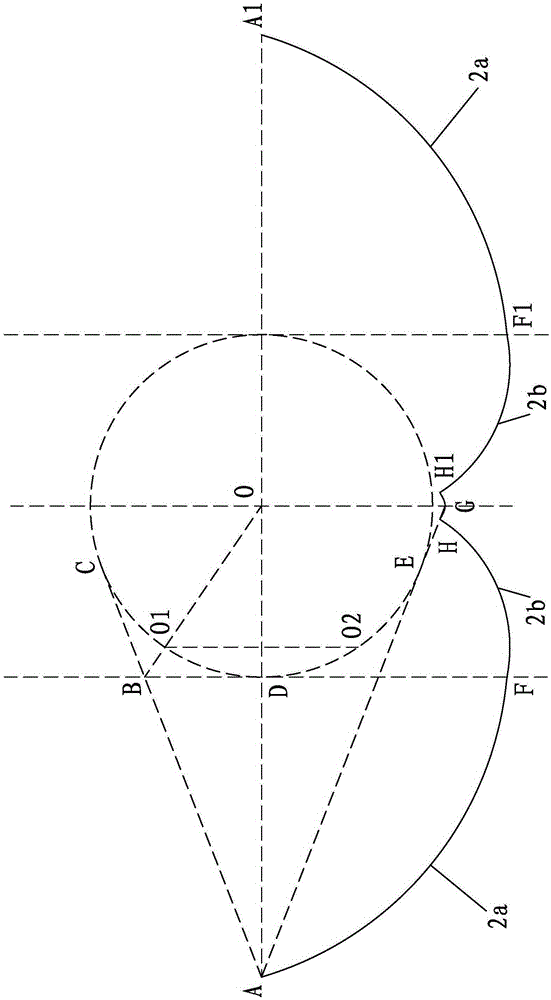

[0034] Such as figure 1 As shown, the solar built-in reflector is arranged below the heat-absorbing pipe. The cross-section of the heat-absorbing pipe is circular, and the circle has a vertical centerline and a horizontal centerline. The cross-sectional shape of the reflector is formed along the vertical centerline. Symmetrical distribution. The heat-absorbing pipe and the reflection plate are arranged in parallel, so the cross-sectional shape and positional relationship of the two are the same in any vertical cross-section.

[0035] The half symmetrical structure of the cross-sectional shape of the reflecting plate is an arc curve segment 2 . The arc curve segment 2 includes several segments of connected arc lines, spec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com