High-pressure gas cylinder inner surface defect detection system based on machine vision

A high-pressure gas cylinder and defect detection technology, which is applied in the direction of optical defect/defect detection, instruments, measuring devices, etc., can solve the problem of limited detection accuracy, emissivity and reflection distance, high training costs for inspectors, and expensive acoustic emission detection equipment To achieve accurate quality inspection, overcome the interference of subjective factors, and improve quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

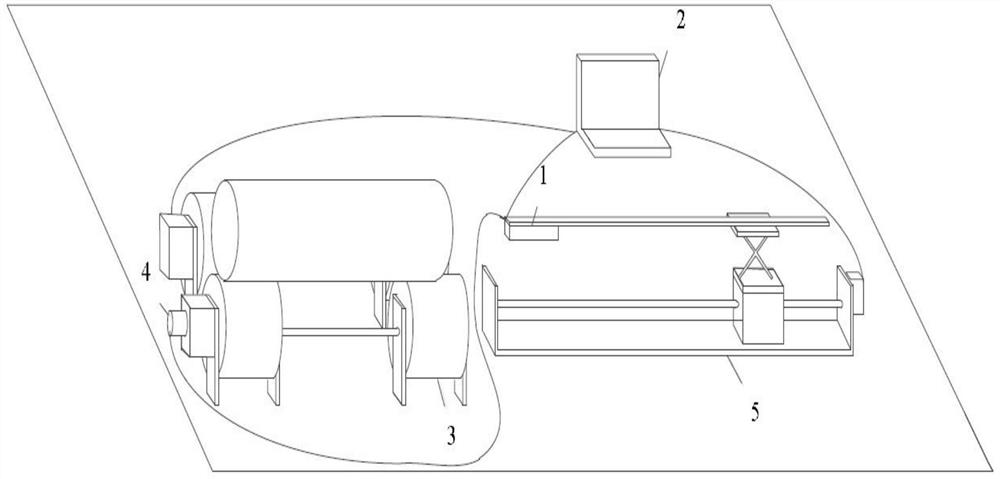

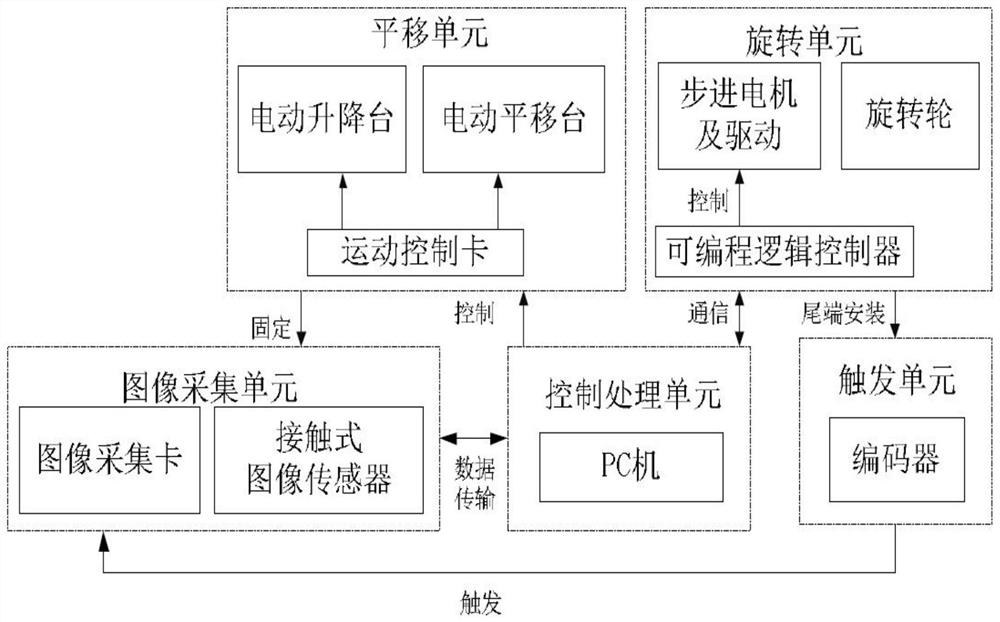

[0036] Such as Figure 1-2 ,Such as Figure 13-14 As shown, the present invention includes an image acquisition unit 1, a control processing unit 2, a rotation unit 3, a trigger unit 4, and a translation unit 5. The image acquisition unit 1 is connected to the control processing unit 2, and the control processing unit 2 is connected to the rotation unit 3 respectively. It is connected with the translation unit 5 , the rotation unit 3 is connected with the trigger unit 4 , the trigger unit 4 is connected with the image acquisition unit 1 , and the image acquisition unit 1 is installed on the translation unit 5 .

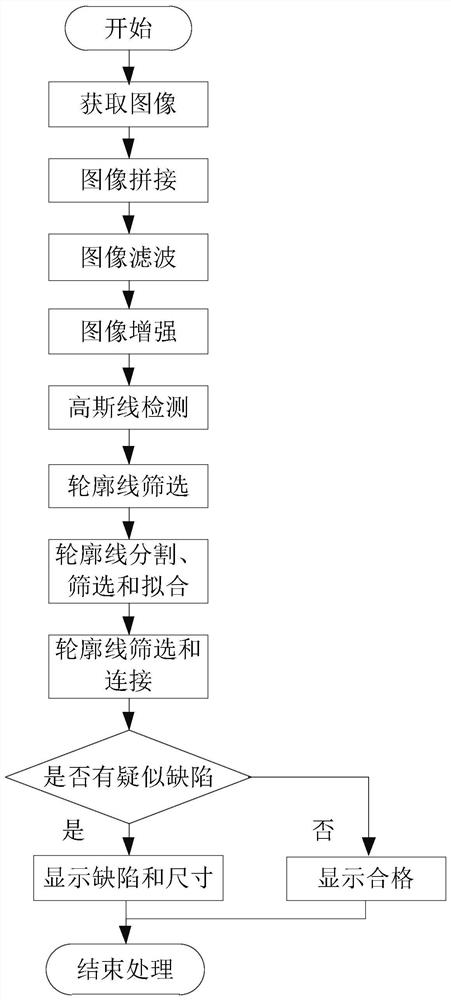

[0037] In this embodiment, the control processing unit 2 is a PC, and image processing software is installed inside, and the image processing software includes an image acquisition module, an image processing module and a parameter output module, and the image acquisition module is used to acquire images The image of the inner surface of the gas cylinder captured by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com