A Template Registration Method for Multi-process Flexographic Print Inspection

A technology for template registration and printed matter, which is applied to measuring devices, material analysis through optical means, instruments, etc., can solve the problems of product image deformation, template set inaccuracy, etc., and achieve reduced process, rapid registration, and improved The effect of detection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

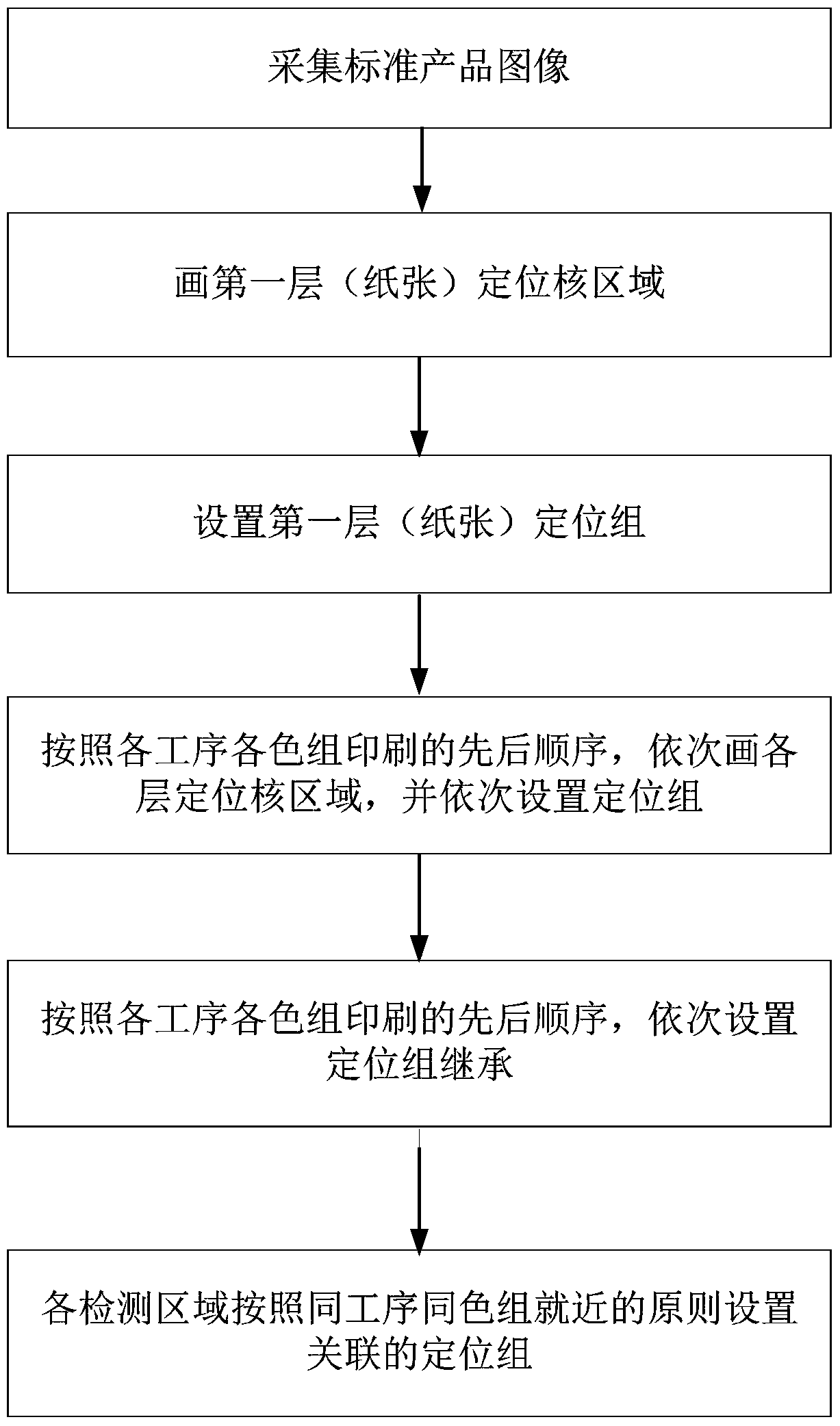

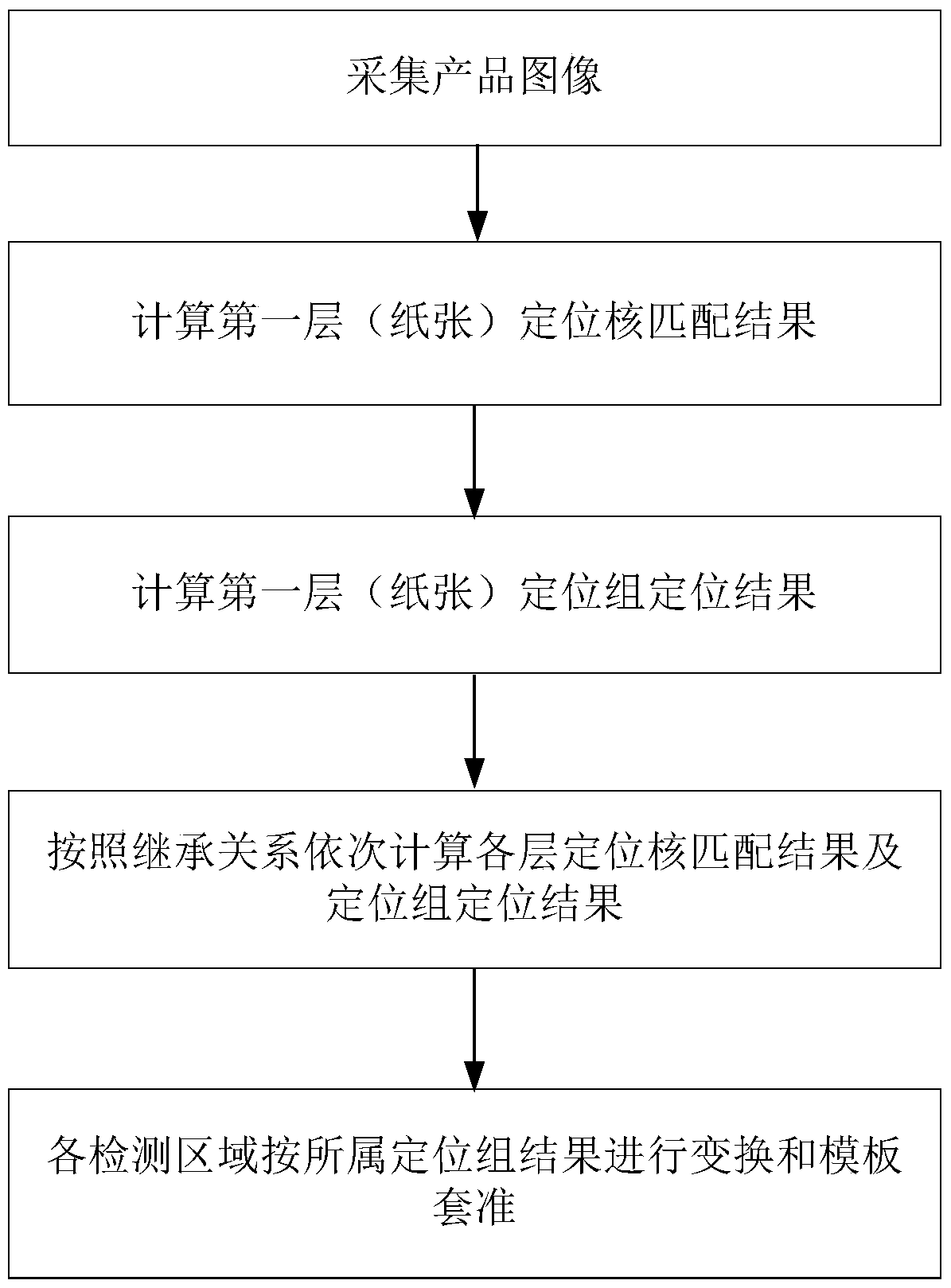

[0061] The template registration method of the present invention is mainly divided into two stages, the template construction stage and the template registration stage.

[0062] Such as figure 1 A schematic flowchart of the template construction phase is shown. First, capture the image of the standard product; then, find and set the positioning group of the product base, for paper printed matter, it is to set the product paper layer positioning group. For example, if image 3 As shown, the paper layer positioning group may include two positioning core areas, and the two positioning core areas correspond to two diagonal points of the paper, and setting the product paper layer positioning group refers to determining the coordinates of the two positioning core areas.

[0063] Next, set up positioning groups for different color groups and diffe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com