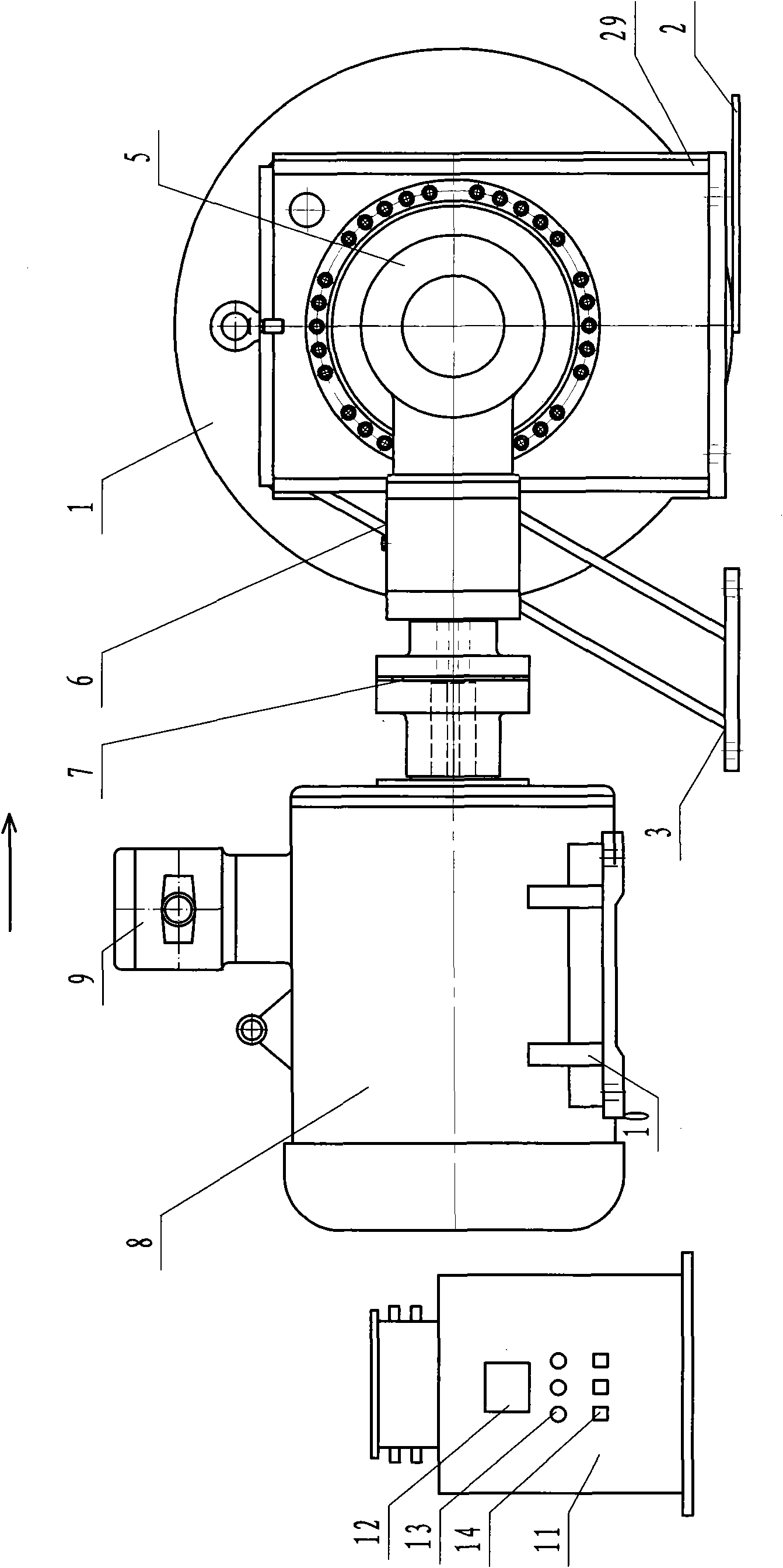

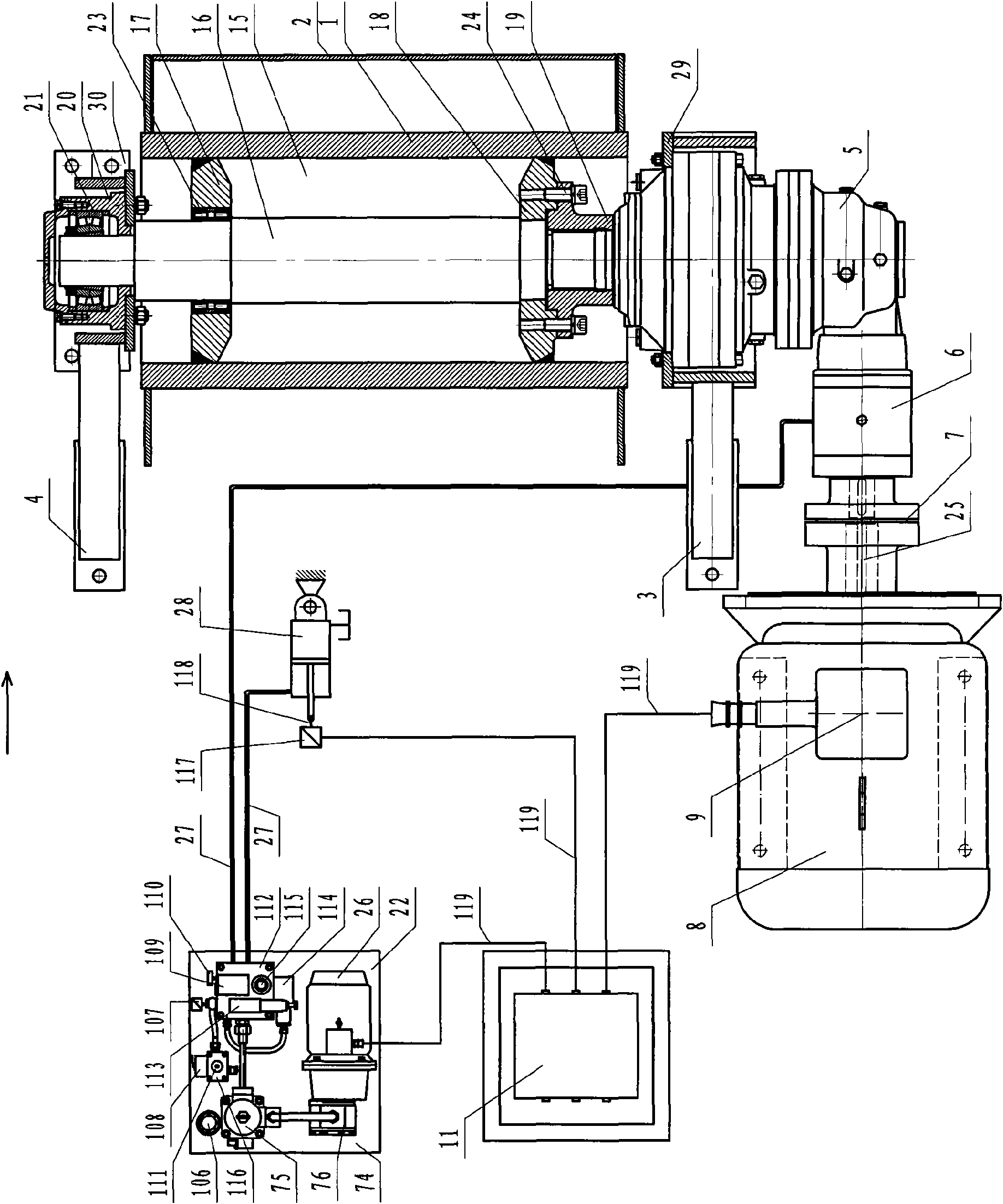

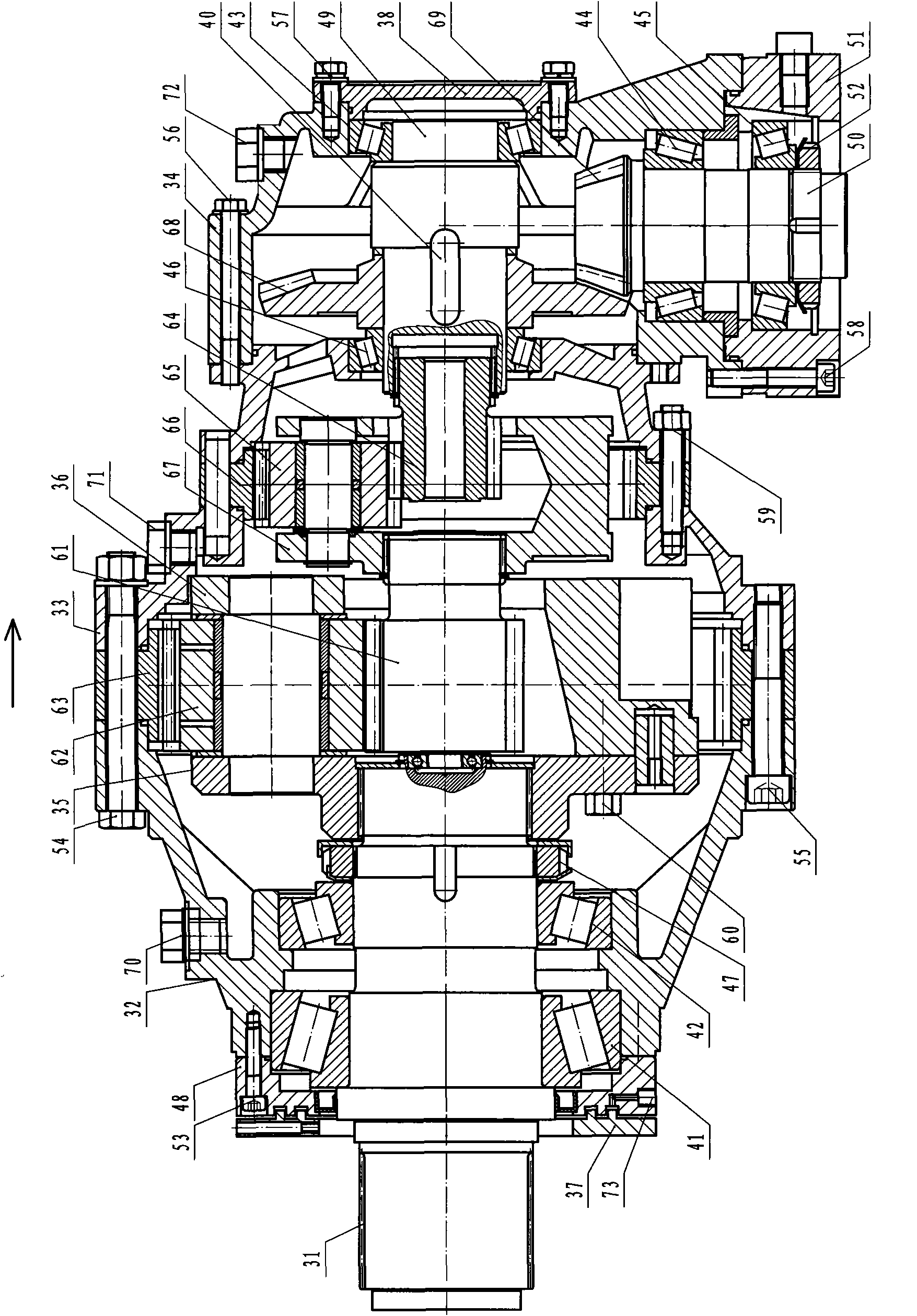

Frequency conversion type automatic tension device of extension band type conveyor

A technology of automatic tensioning device and conveyor, applied in the direction of conveyor, transmission device, transmission device parts, etc., can solve problems such as inability to automatically adjust, high tension at the separation point, broken belt or damage to the automatic tensioning device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] This device can choose three modes: automatic, manual, take-up

[0038] Automatic working mode: In the automatic working state, when the telescopic belt conveyor sends out three different working condition signals in the starting stage, running stage and stopping stage, it can automatically adjust the tension of the tape, and can also adjust the tension according to different working conditions The speed is automatically adjusted.

[0039] Manual working mode: In the manual working state, the tension can be increased or decreased through the belt tightening or loosening button. In order to prevent the conveyor belt from piled up, the belt tension cannot be lower than the lower limit of the tension in the manual working state.

[0040] Take-up working mode: In the working state of take-up, this device cooperates with the take-up device of the telescopic belt conveyor. To the optimum value, it not only ensures that the take-up device can recycle excess tape to the take-u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com