Construction method of cast-in-place concrete hollow slab with self-stabilizing high-strength thin-wall pipe inner mold

A construction method and technology for hollow concrete slabs, which are applied to floors, building components, buildings, etc., can solve problems such as self-stabilization and anti-floating performance, environmental protection and energy saving defects in installation and installation, and achieve good self-stabilizing and anti-floating performance, cost saving, and work efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

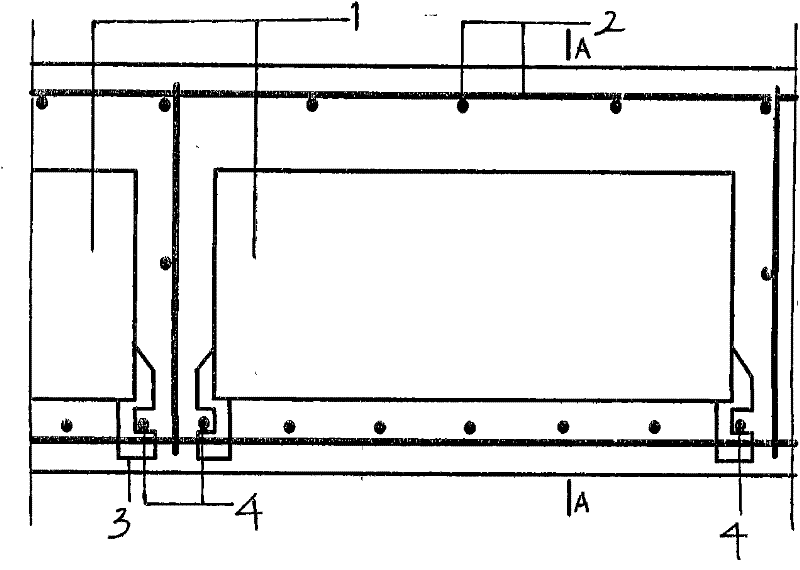

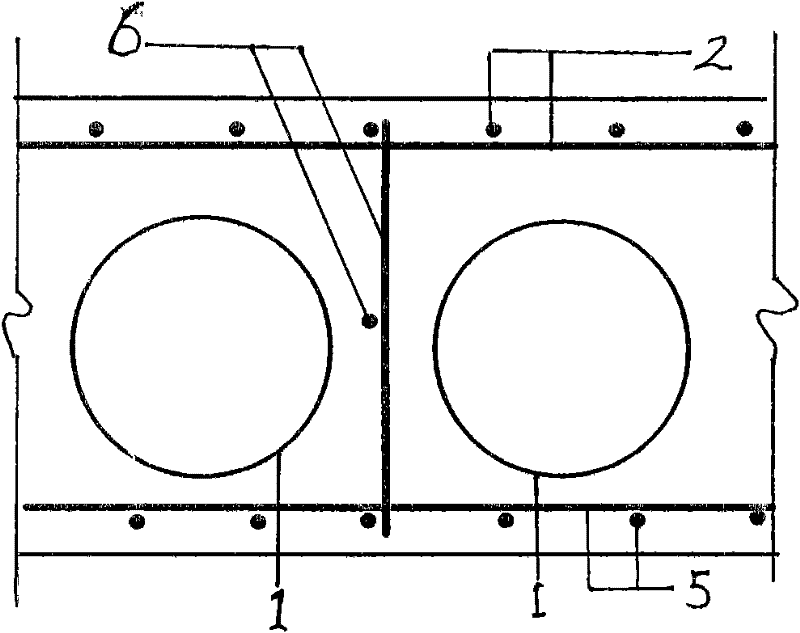

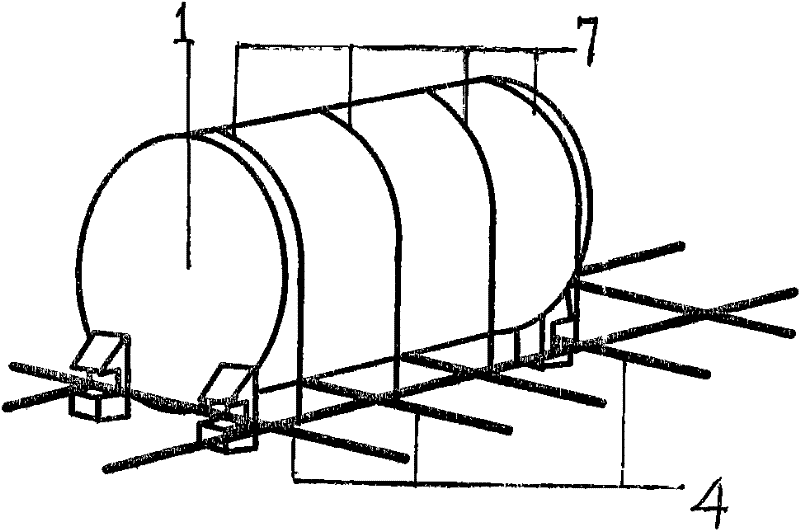

[0026] A self-stabilizing high-strength thin-walled pipe internal formwork (abbreviated as the internal formwork) cast-in-place concrete hollow slab construction method is characterized in that it includes the following steps:

[0027] (1) Installation template: According to the indoor horizontal line, use a spirit level to measure the elevation of the floor floor, use bowl-buckle steel pipe scaffolding or scaffolding steel pipes as horizontal supports, adjustable supporting steel pipes as vertical supports, and 50mm×100mm wooden squares as the receiving The keel is covered with bamboo plywood or multi-layer plywood, and the two-way arching of the formwork is 0.1-0.3% of the span;

[0028] (2) Spring line positioning: After the formwork is installed, pop up the position center line and end line of the self-stabilizing high-strength thin-walled pipe inner mold, and then pop up the identification lines of hidden beams, reserved holes, pre-embedded pipelines, and bottom steel bars...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com