Self-locking fastener

A fastener and self-locking technology, which is applied in the field of connecting tools for fixing the device to be fixed and the mounting frame, achieves the effect of reducing lateral clearance, ensuring reliability and increasing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

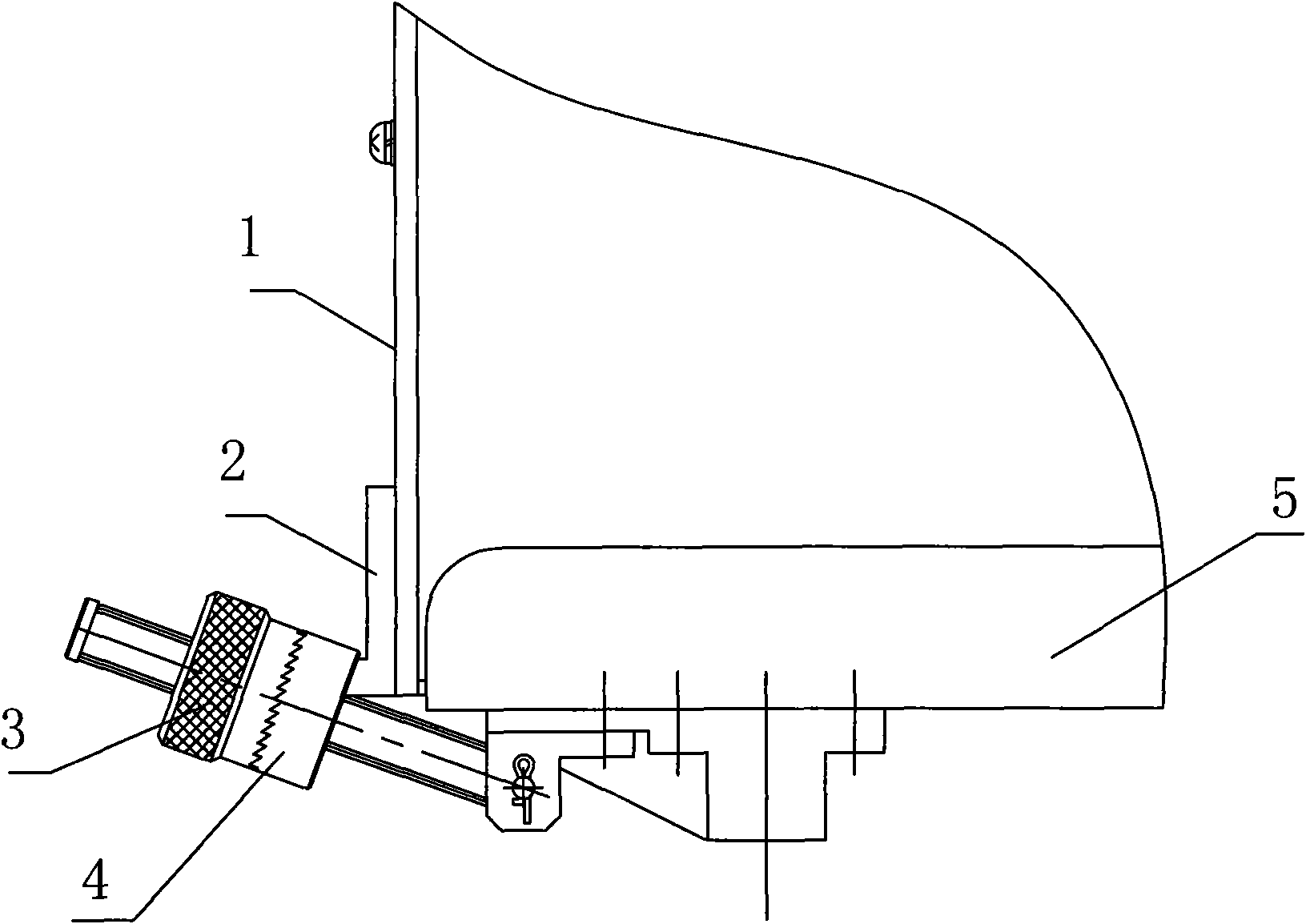

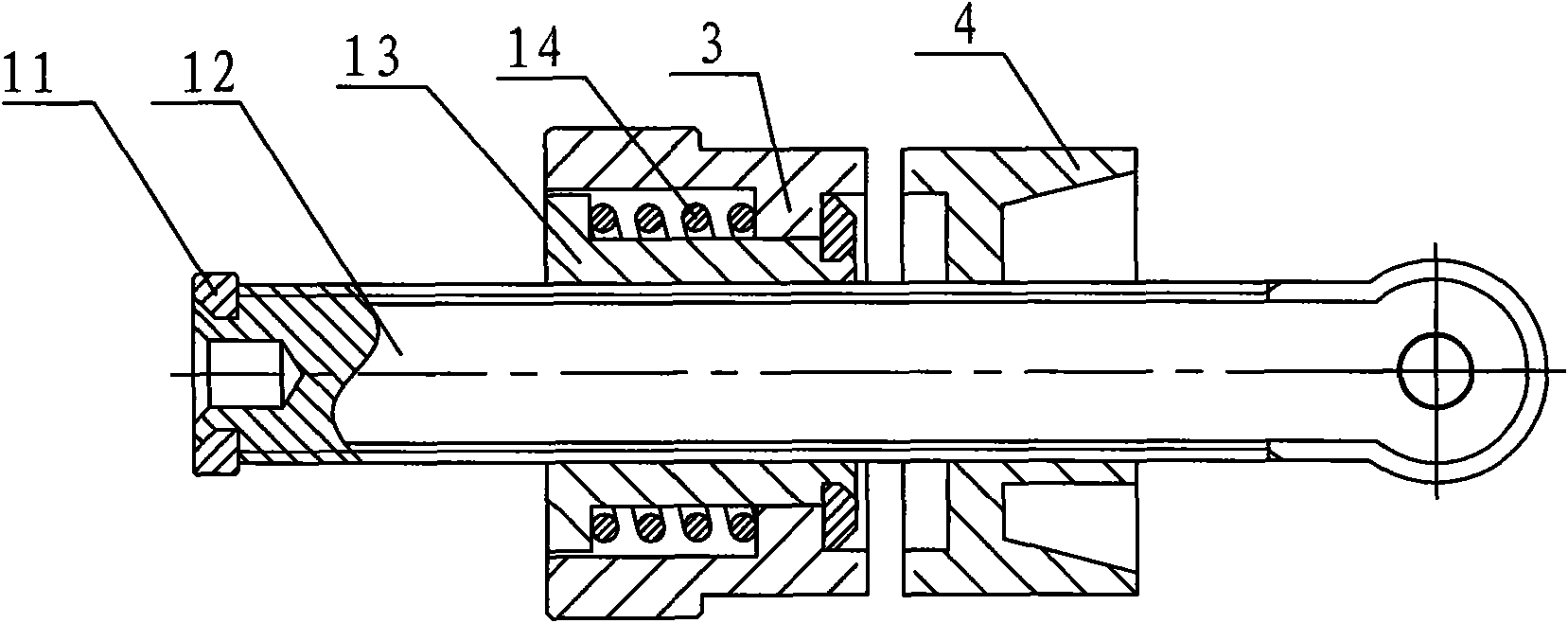

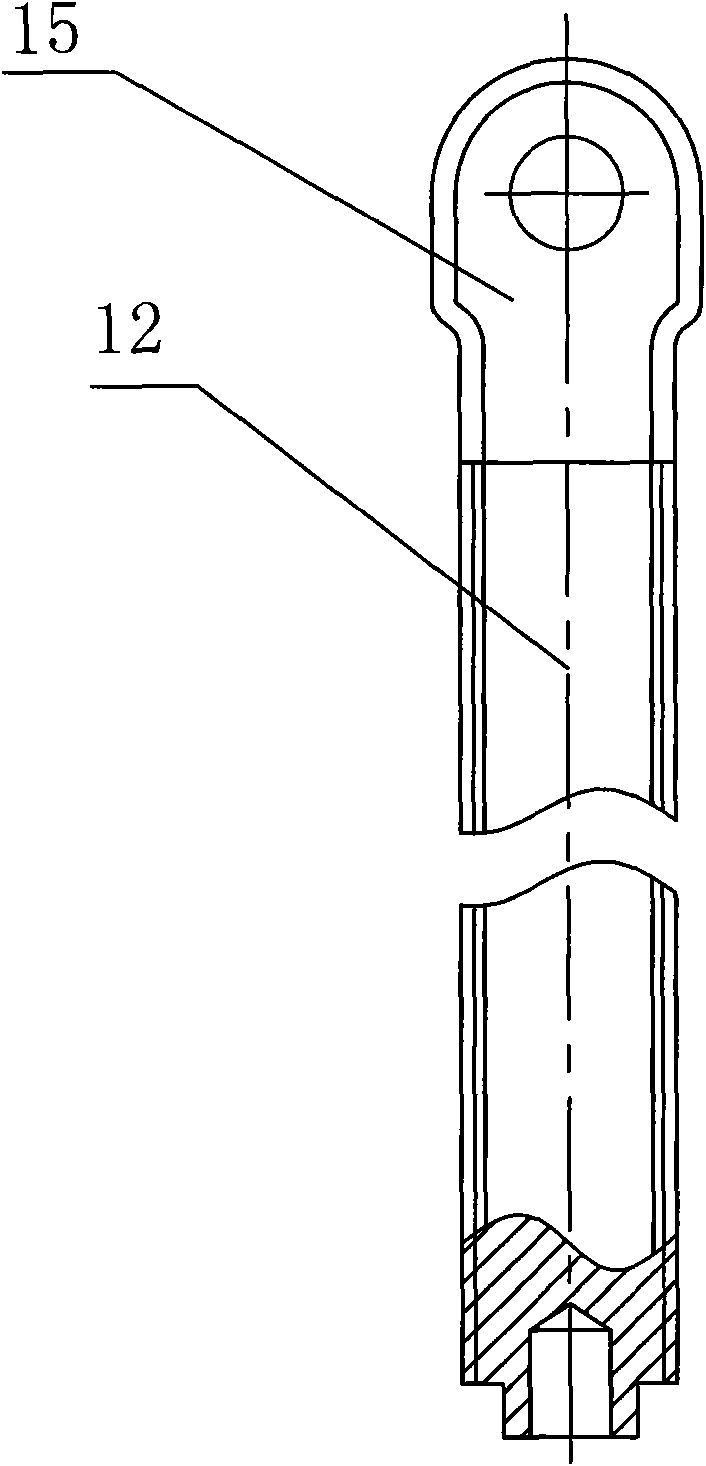

[0023] Figure 1~Figure 8 As shown, the self-locking fastener of the present invention includes a fastening screw 12, and one end of the fastening screw 12 is provided with a hinge hole for hinged connection with the mounting frame. Of course, the locking hook and the mounting frame 5 can also be used. For connection, a retaining ring 11 is riveted at the other end of the fastening screw 12. The fastening screw 12 is provided with a pair of mutually parallel anti-rotation mating surfaces 15 extending in the axial direction of the fastening screw. Of course, the anti-rotation mating surfaces may not be parallel to each other, and the number of anti-rotation mating surfaces is not limited to only one. Correct. The fastening screw 12 is provided with a lower gear sleeve 4 and an upper gear sleeve assembly in series, the lower gear sleeve 4 is located at an end close to the hinge hole, and the upper gear sleeve assembly is located at a position away from the hinge hole. The retai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com