Application of acetic acid or acetic acid and ammonium sulfate for removing heavy metals in garbage compost

A waste composting and heavy metal technology, applied in organic fertilizers, climate change adaptation, etc., can solve secondary pollution and other problems, and achieve the effect of simple operation, wide application prospects, and remarkable rinsing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1) Compost the household garbage containing heavy metal pollution, sieve and sort, air-dry, grind, sieve, and set aside;

[0036] 2) The fine sand was treated with 1% H 2 SO 4 After cleaning, dry at 100°C for 24 hours to filter the bottom layer;

[0037] 3) Put the treated fine sand and garbage compost into the rinse device, rinse with ammonium sulfate and acetic acid mixture, after the rinse, leave the rinse for 48 hours; the weight of the compost and the mixture The ratio of parts and numbers is 1:10; wherein the ratio of parts and weights of ammonium sulfate and acetic acid mixed solution is: 40mmol / L acetic acid: 1g / L (NH 4 ) 2 SO 4 =1:2.5.

[0038] 4) Rinse the compost with water again, collect the eluate, let stand after rinsing until there is no more eluent dripping out, leave it for 24 hours, then rinse the compost for the second time, rinse three times in total, and collect the eluate;

[0039] 5) combining the eluents collected in 3), 4) and performing d...

Embodiment 2

[0042] 1) Compost the household garbage containing heavy metal pollution, sieve and sort, air-dry, grind, sieve, and set aside;

[0043] 2) Wash the fine sand with 1% H2SO4 and dry it at 100°C for 24 hours to filter the bottom layer;

[0044] 3) Put the processed fine sand and garbage compost into the rinse device, rinse with 40mmol / l acetic acid, after the rinse is completed, leave the rinse solution for 48 hours; wherein the ratio by weight of acetic acid to compost is It is 1:2-10.

[0045] 4) Rinse the compost with water again, collect the eluate, let stand after rinsing until there is no more eluent dripping out, leave it for 24 hours, then rinse the compost for the second time, rinse three times in total, and collect the eluate;

[0046] 5) combining the eluents collected in 3), 4) and performing digestion treatment to obtain powder;

[0047] 6) Dilute the obtained powder to volume with 1% dilute nitric acid, then measure the concentration of various heavy metals

Embodiment 3

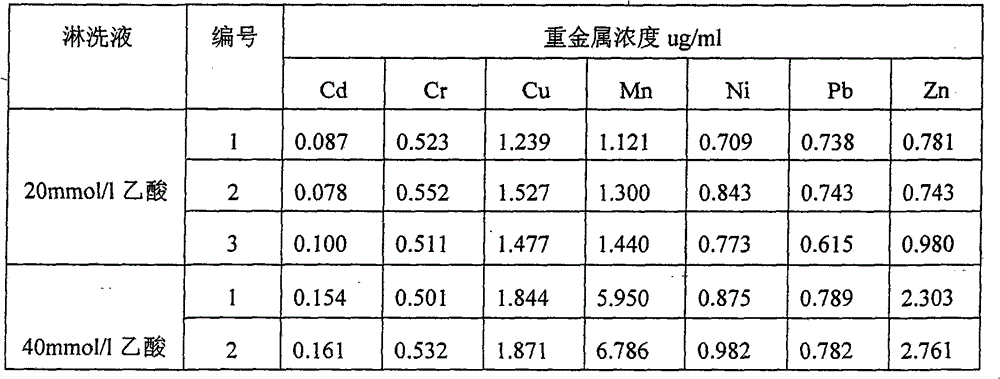

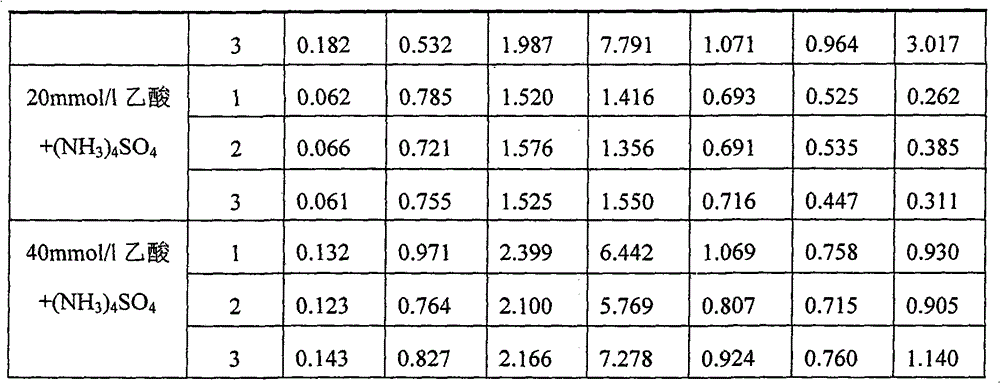

[0048] Embodiment 3 (more detailed experimental process is as follows):

[0049] Experimental Materials

[0050] Garbage composting treatment: drying at 100°C for 24 hours; fine sand: 1% H 2 SO 4 Dry at 100°C for 24 hours after cleaning. PVC pipe: 1.5CM in diameter, 20CM in height; a total of 18 pipes are numbered 1 to 3 in each group and sealed with cloth. Compost filling: Weigh 20g of fine sand at the bottom of the washing tube, then fill with 110g of compost, a total of 18 sticks. Weighing: Weigh the weight of 18 plastic bottles that will contain the filtrate.

[0051] experimental drug

[0052] Acetic acid: 17.6Mol / L; HNO 3 ; (NH 3 ) 4 SO 4 ;perchloric acid

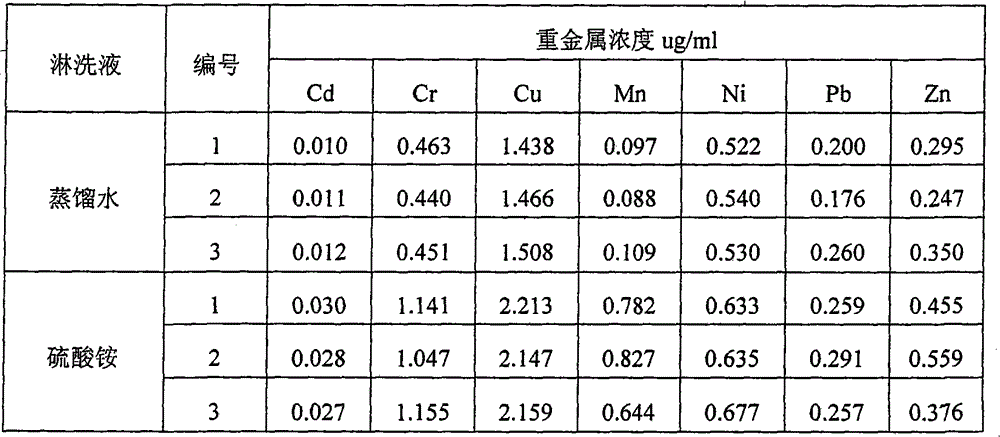

[0053] Table 1 Eluent formula

[0054] eluent

Acetic acid (ml)

Ammonium sulfate (g)

20mmol / l acetic acid

1.3636

0

40mmol / l acetic acid

2.2727

0

20mmol / l acetic acid+(NH 3 ) 4 SO 4

1.3636

0.5186

40mmol / l acetic acid+(NH 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com