Resource recycling method of waste ammonium alkali liquid for well injection and brine extraction of sodium sulfate type salt mine

A technology of resource utilization and sodium sulfate, which is applied in the directions of alkali metal chlorides, mining fluids, earthwork drilling, etc., to achieve the effects of being beneficial to environmental protection, reducing production costs, and improving mining quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

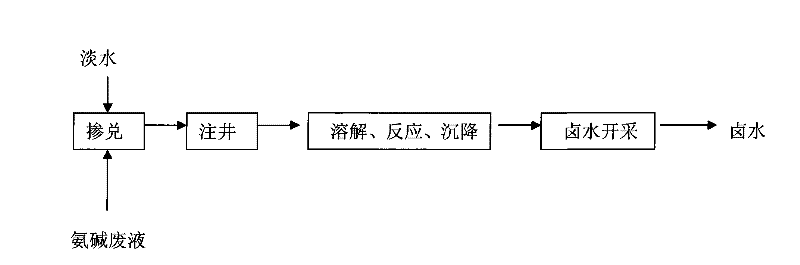

Image

Examples

Embodiment 1

[0033] It is required that the sodium sulfate content in the mined brine should be about 10g / l. The ratio of ammonia-alkali waste liquid to fresh water is 1:11, that is, after 1 part of ammonia-alkali waste liquid is mixed with 11 parts of fresh water, it is injected into the rock salt mine, and rock salt is dissolved in the mine, and calcium chloride and sodium sulfate react to form calcium sulfate precipitation. , after sufficient time for settlement, mining bittern saturated with NaCl and with a sodium sulfate content of about 10g / l.

[0034] The mined brine can be used for vacuum salt making.

Embodiment 2

[0036] It is required that the sodium sulfate content in the mined brine should be about 4g / l. The ratio of ammonia-alkali waste liquid to fresh water is 1:7.5, that is, after 1 part of ammonia-alkali waste liquid is mixed with 7.5 parts of fresh water, it is injected into the rock salt mine, and rock salt is dissolved in the mine, and calcium chloride and sodium sulfate react to form calcium sulfate precipitation. , after a sufficient time of settlement, mineral bittern saturated with NaCl and with a sodium sulfate content of about 4g / l is mined.

[0037] The mined brine is refined liquid salt, which can be sold directly to the outside world.

Embodiment 3

[0039] It is required that the mined bittern should have a sodium sulfate content of 0g / l and a calcium chloride content of 5g / l. The ratio of ammonia-alkali waste liquid to fresh water is 1:4.9, that is, after mixing 1 part of ammonia-alkali waste liquid with 4.9 parts of fresh water, it is injected into the rock salt mine, and rock salt is dissolved in the mine, and calcium chloride and sodium sulfate react to form calcium sulfate precipitation. After sufficient time for settlement, mineral bittern saturated with NaCl, with a sodium sulfate content of 0g / l and a calcium chloride content of about 5g / l is mined.

[0040] The mined bittern ore can be used as raw material for beach sun-dried salt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com