Feeding device and recording device

A technology of conveying device and recording medium, which is applied in the directions of transportation and packaging, separation of objects, separation of piles, etc., and can solve problems such as formation of gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

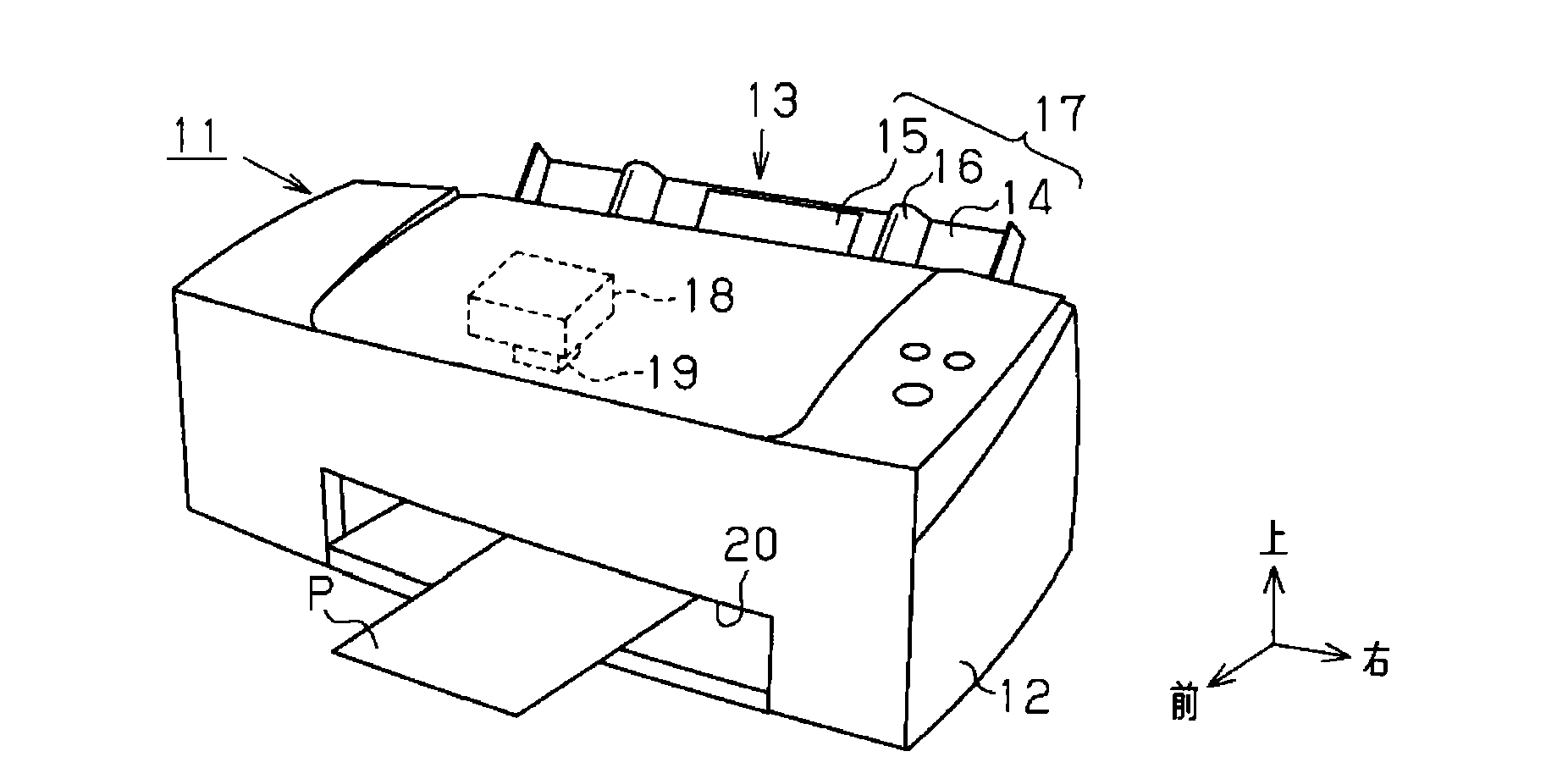

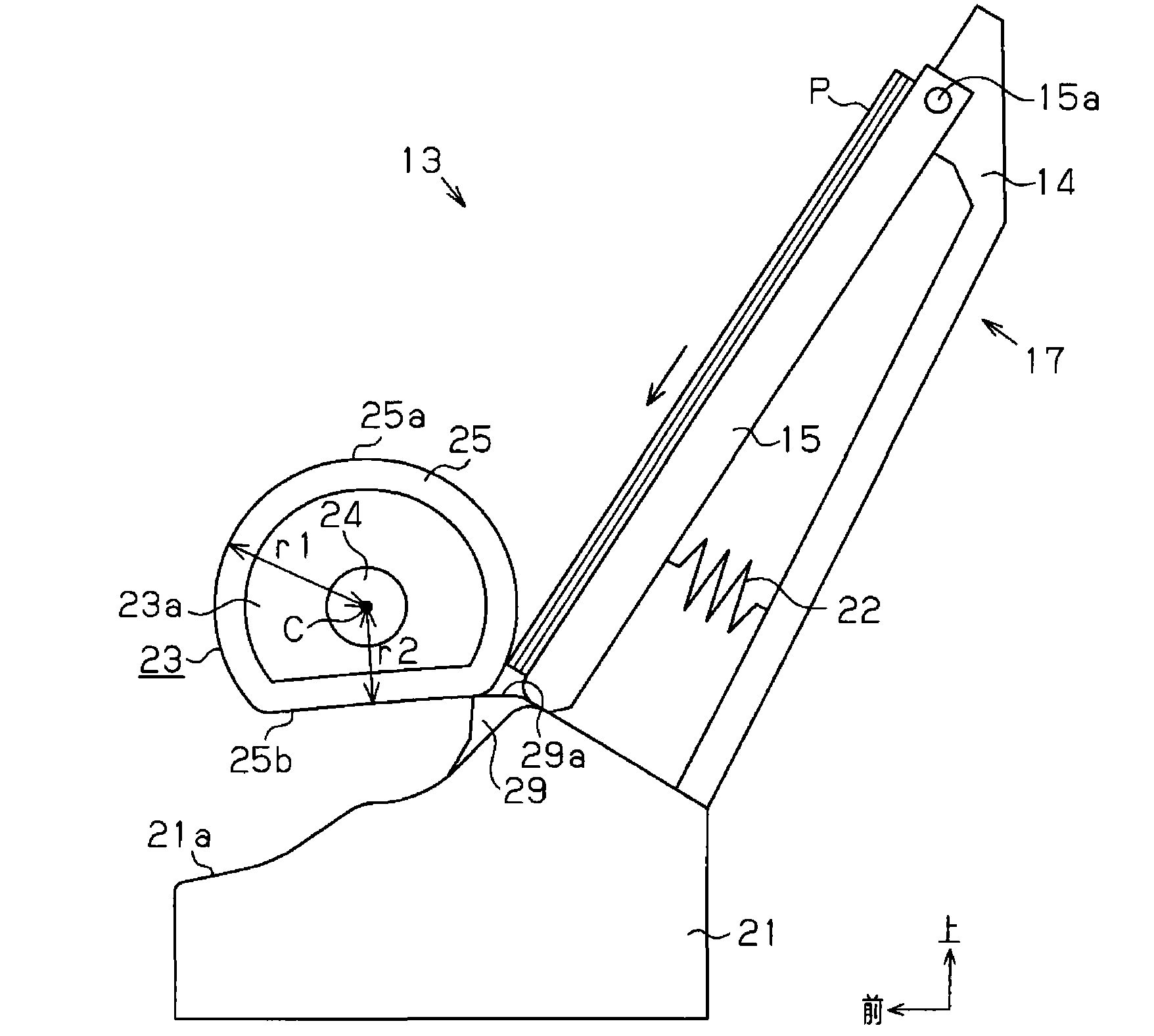

[0030] Below, use Figure 1 to Figure 5 An embodiment in which the recording device including the transport device according to the invention of the present application is embodied as an inkjet printer (hereinafter referred to as "printer") will be described. In addition, in the following description, when referring to "front-rear direction", "left-right direction", and "up-and-down direction", it means the direction based on the direction shown by the arrow in each figure.

[0031] Such as figure 1 As shown, in the printer 11 of this embodiment, an automatic paper feeder 13 serving as a conveying device for feeding paper P as a recording medium is equipped on the rear side of the main body 12 . A paper guide 17 serving as a loading unit is attached to the automatic paper feeder 13 . The paper guide 17 has a paper feed tray 14 , a hopper 15 , and an edge guide 16 . Also, the automatic paper feeder 13 has a paper feed drive mechanism (not shown) that feeds the paper P placed ...

no. 2 approach

[0052] Below, according to Figure 6 A second embodiment in which the liquid ejecting apparatus of the present invention is embodied as a serial type inkjet printer will be described.

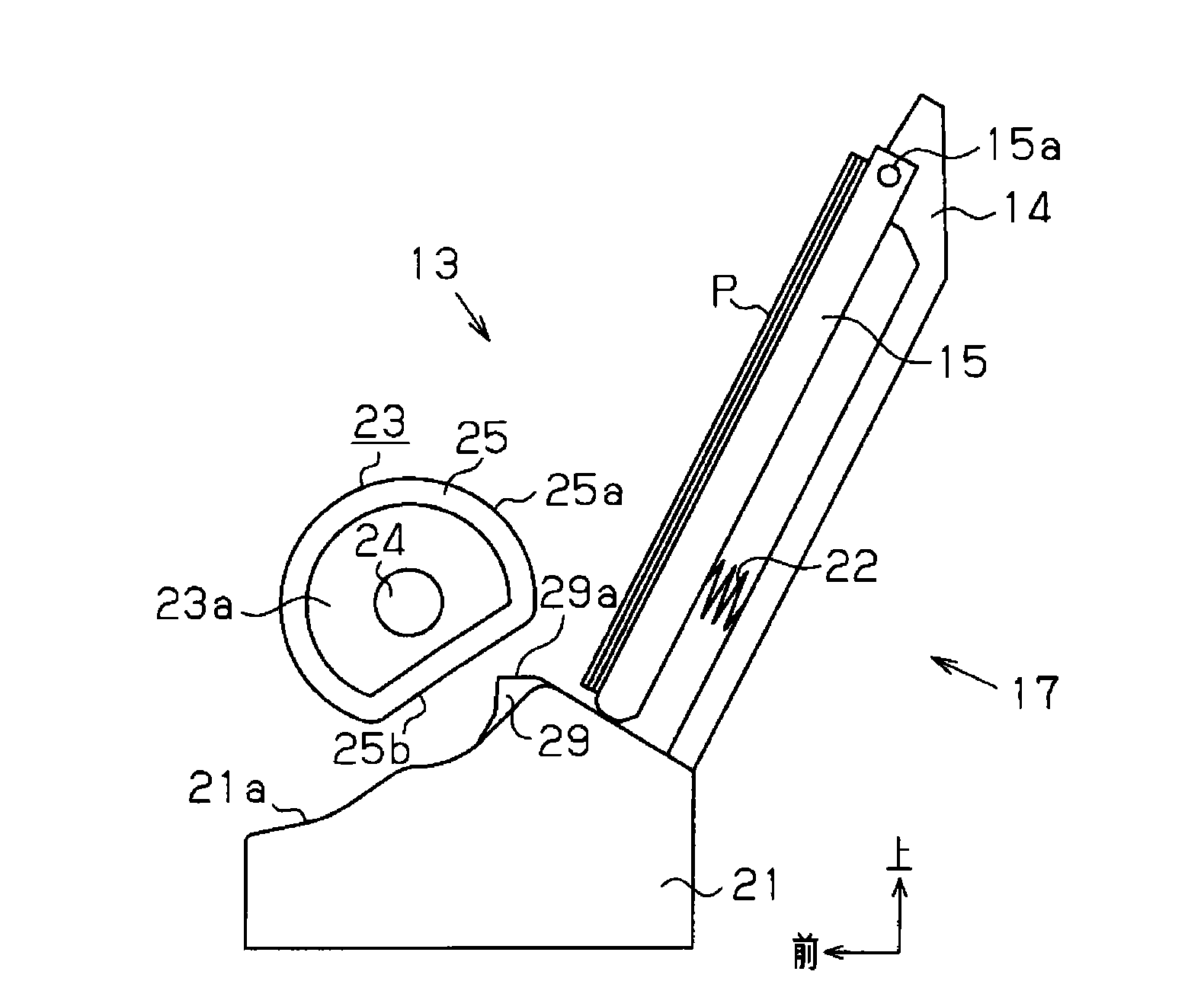

[0053] This embodiment is the same as the first embodiment in that in the automatic paper feeder 13 included in the printer 11 as a recording device, the paper feed roller 23 and the separation member 29 cooperate to separate the paper P. However, The guide roller 23 of this embodiment differs from 1st Embodiment in the point which has the spring member which biases the contact surface forming member 25 via a slider.

[0054] Hereinafter, the description will focus on points different from the first embodiment.

[0055] Such as Figure 6 As shown, in the inside of the base portion 23a of the paper feed roller 23, a storage hole is formed between the rotating shaft 24 and the abutment surface forming member 25 and at the part that abuts the separation member 29 when the paper P is separated. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com