Feed device and recording device

A technology of conveying device and placing part, which is applied in the directions of transportation and packaging, separation of objects, separation of piles, etc., can solve problems such as overlapping conveying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

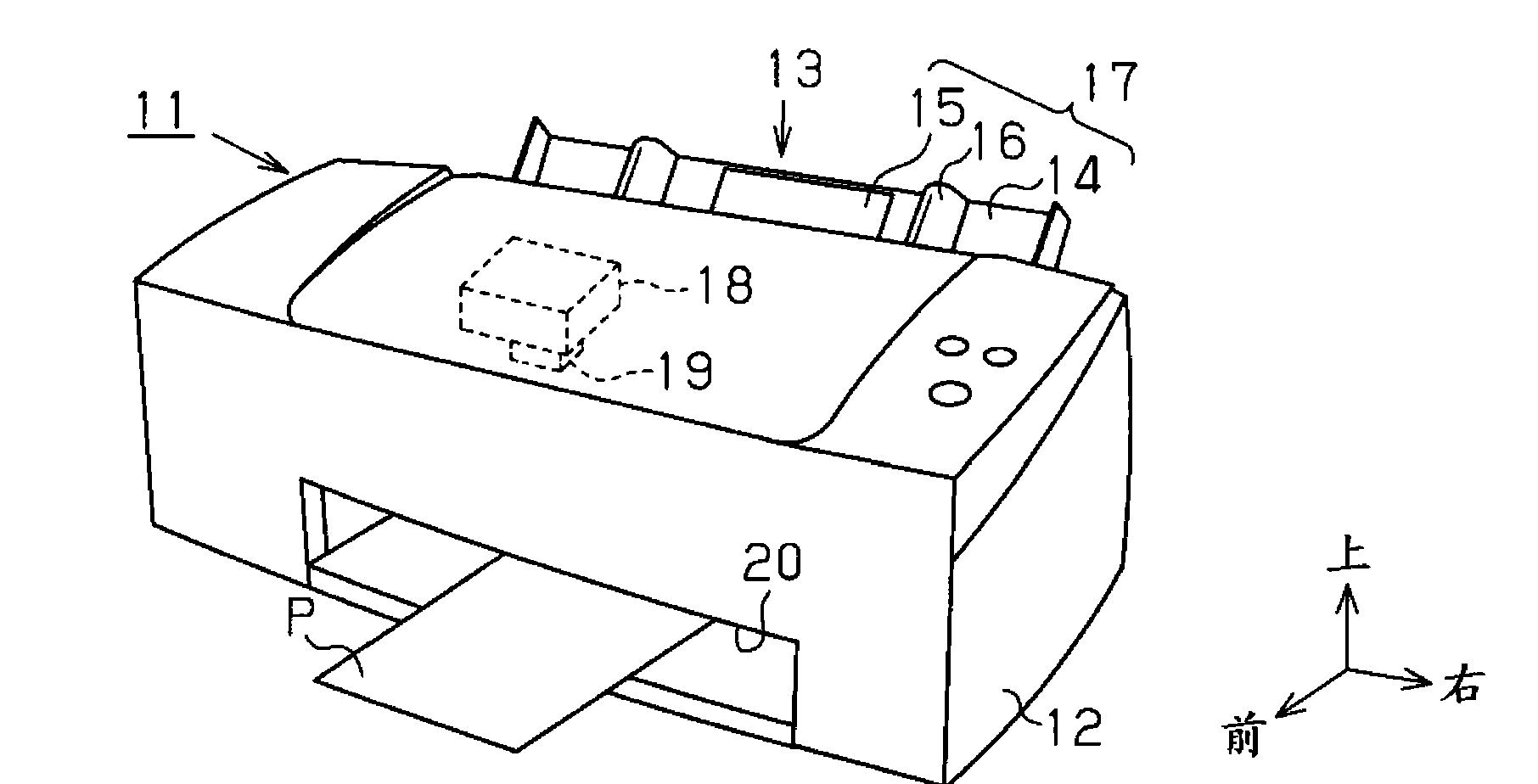

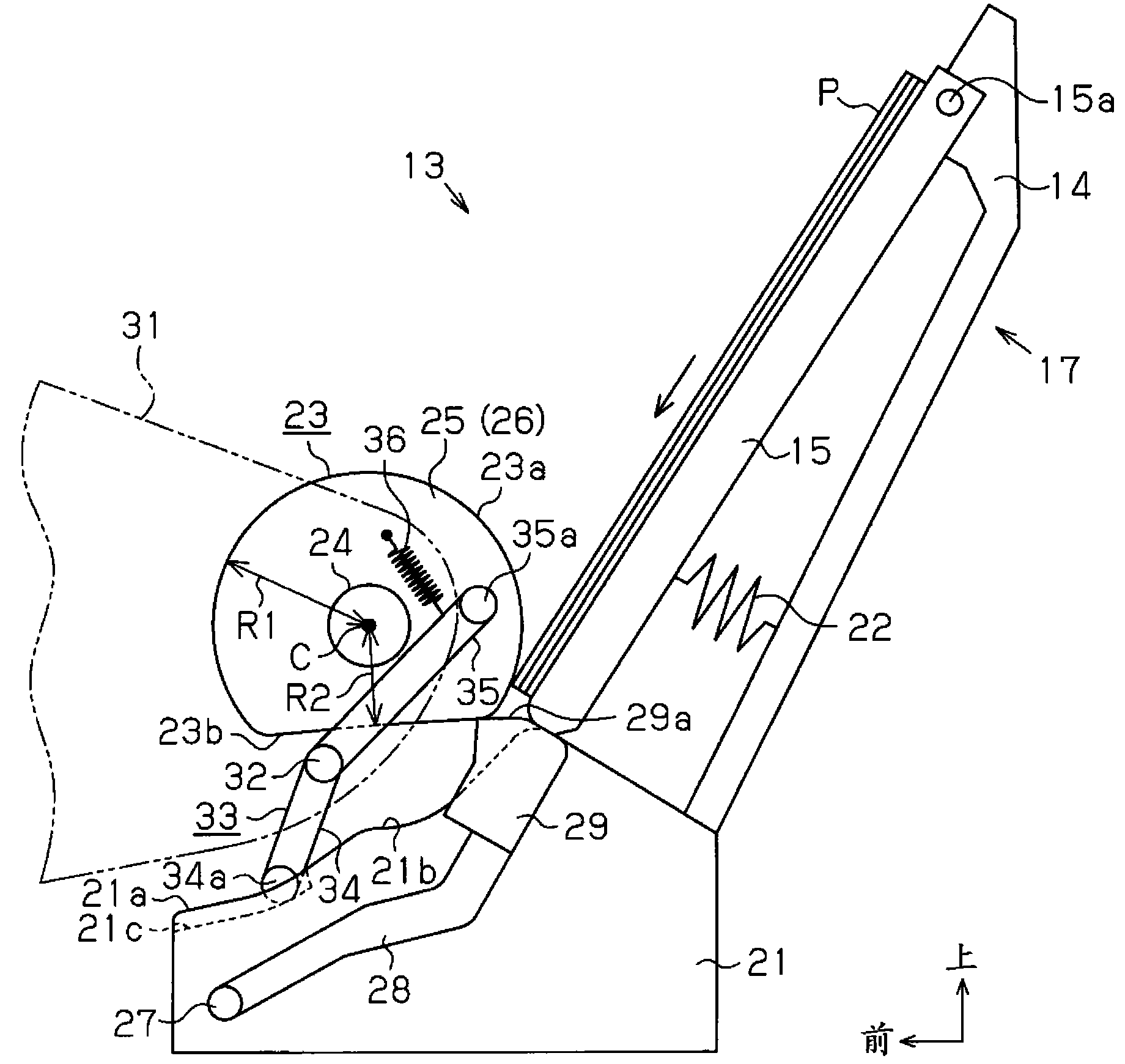

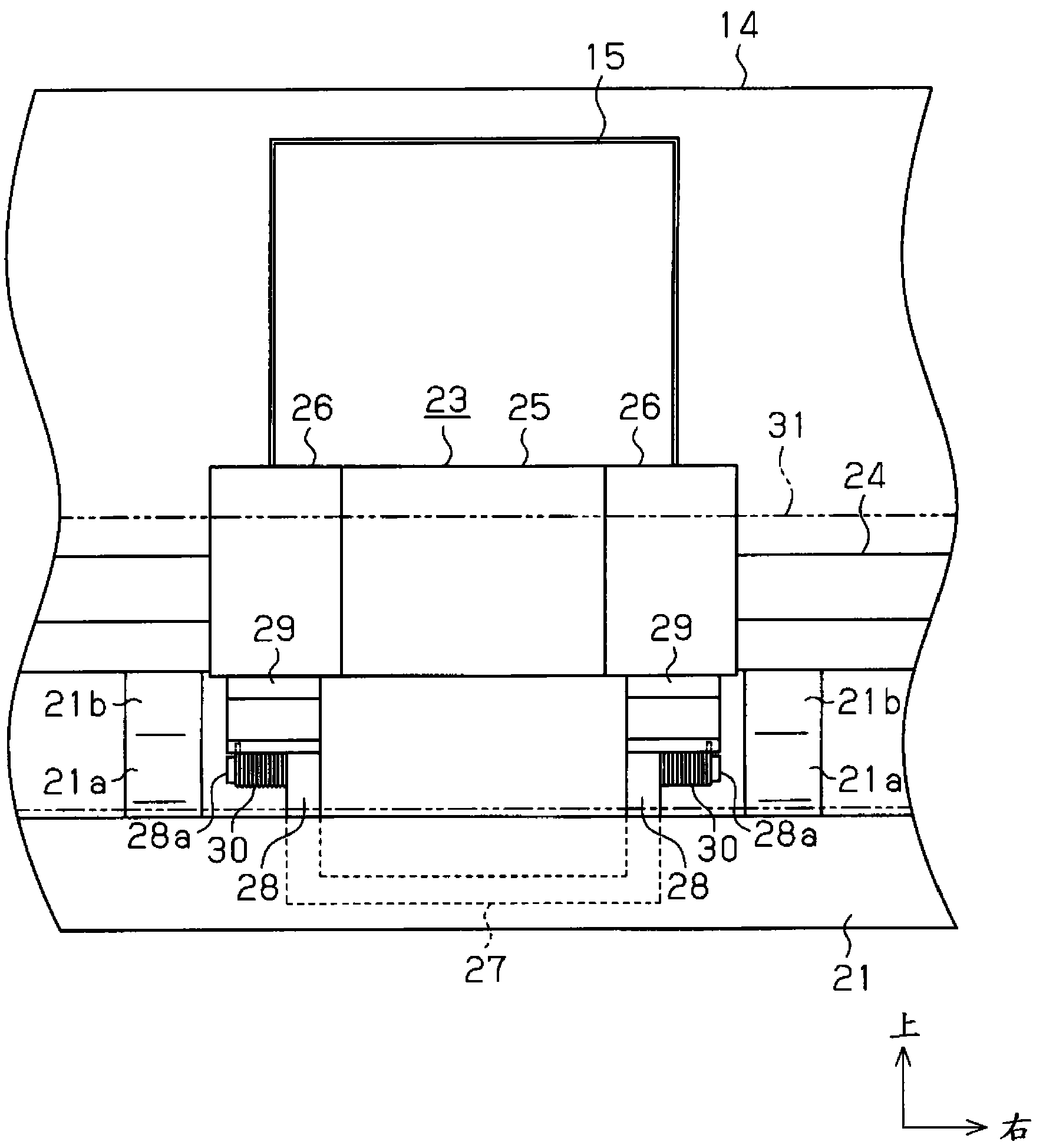

[0032] Hereinafter, an embodiment in which the recording device of the present invention is embodied as an inkjet printer (hereinafter referred to as "printer") will be described with reference to the drawings. In addition, in the following description, when referring to "front-rear direction", "left-right direction", and "up-and-down direction", it means the direction based on the direction shown by the arrow in each drawing.

[0033] like figure 1 As shown, a printer 11 as a recording device includes a substantially rectangular parallelepiped main body 12, and an automatic paper feeder 13 as a conveying device is mounted on the back side of the main body 12, and the automatic paper feeder 13 is used to supply the paper p. The automatic paper feeder 13 has: a paper guide 17 as a loading section having a paper feed tray 14, a hopper 15, and an edge guide 16; and paper guides 17 to be loaded in a stacked state. The paper P is supplied one by one to a paper feeding drive mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com