Wiper blade

A technology for a wiper strip and a stopper is applied in the field of wiper strips, which can solve the problem of not being able to reliably prevent a wiper lip windshield from occupying an undesired angle, and achieve the effect of avoiding interference noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

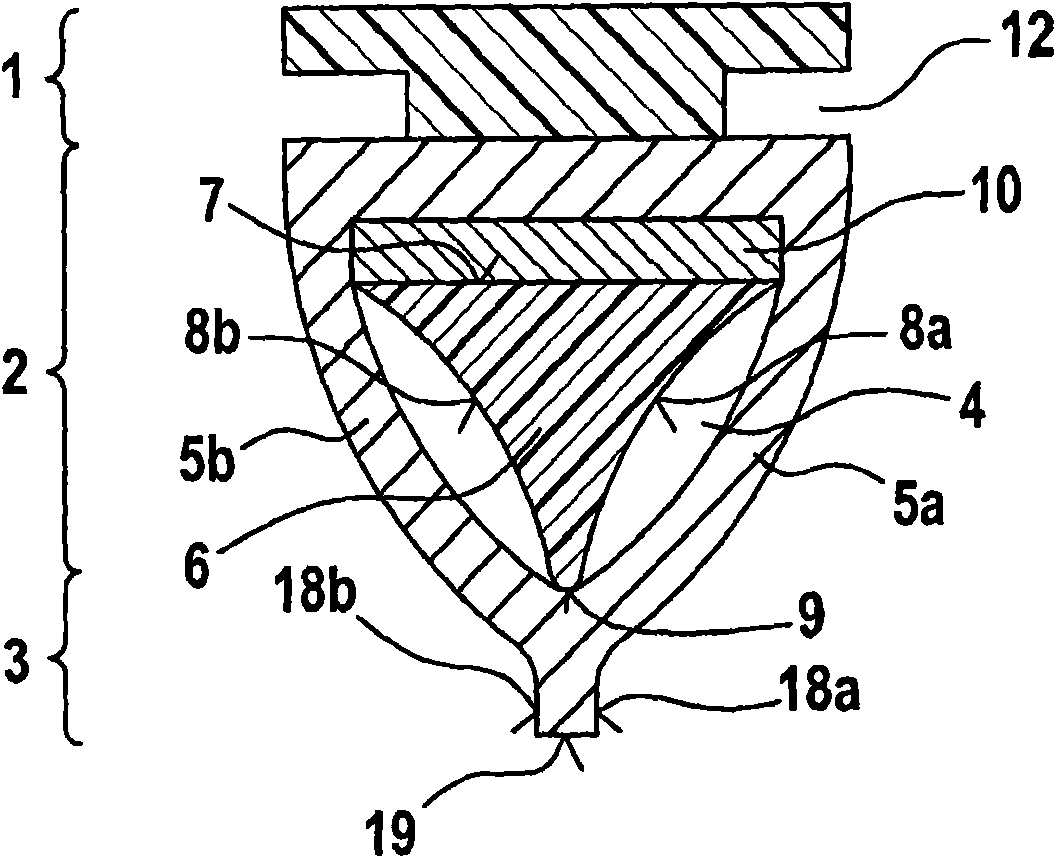

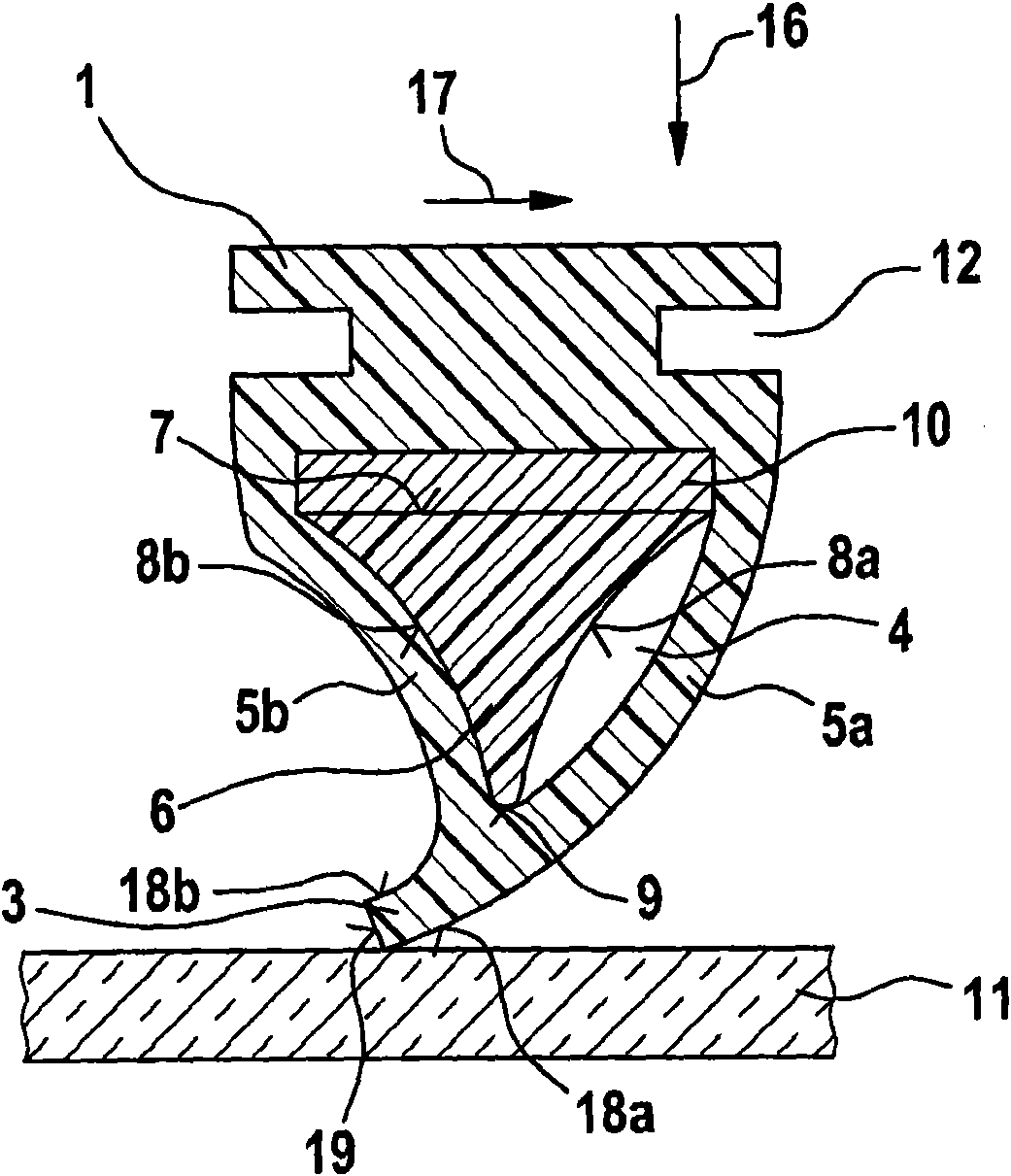

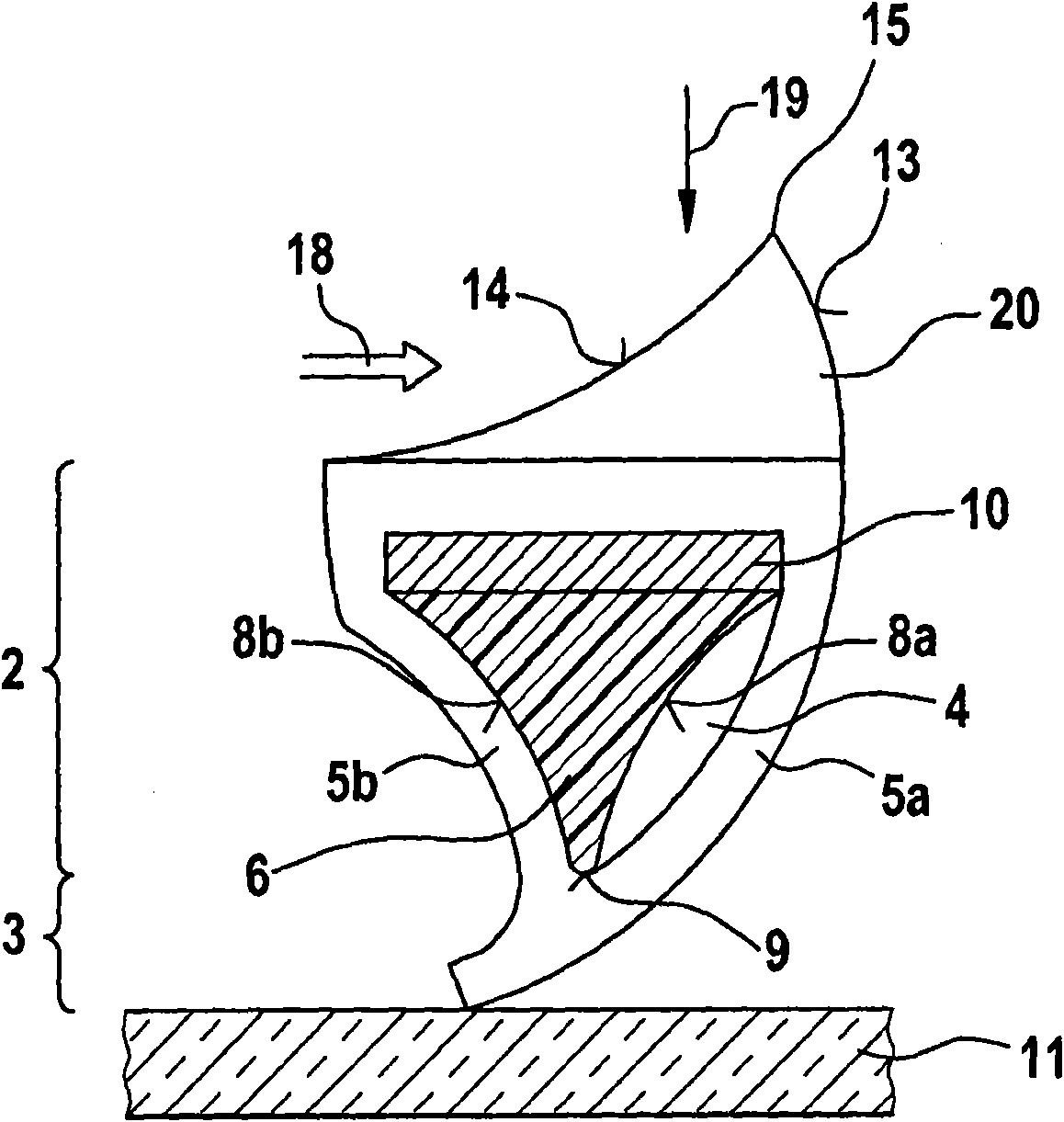

[0020] figure 1 A cross-section of the wiper strip proposed by the invention is shown. The cross section is subdivided into a fastening part 1 and a wiper lip 3 , which are connected to each other by a central part 2 .

[0021] according to figure 1 According to the embodiment, the fixed part 1 has a substantially T-shaped cross-section. Grooves 12 are thus formed on both sides of the wiper strip, on which a fastening device, which is arranged at the end of a wiper arm, can act. The fastening part 1 can now be made of a polymer. figure 1 The shown cross section can be constant over the entire longitudinal extent of the wiper strip. This makes it possible to position the wiper arm arbitrarily along the longitudinal extent of the wiper strip. In another embodiment of the invention, however, the fastening part 1 is arranged only at predetermined positions along the longitudinal extent of the wiper strip, so that a defined positioning of the wiper strip on the arm of the wipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com