Sealing diaphragm and check valve having a sealing diaphragm for fluid technology applications

A technology of sealing film and sealing section, applied in the direction of valve device, control valve, functional valve type, etc., can solve problems such as disadvantages and achieve the effect of avoiding interference and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

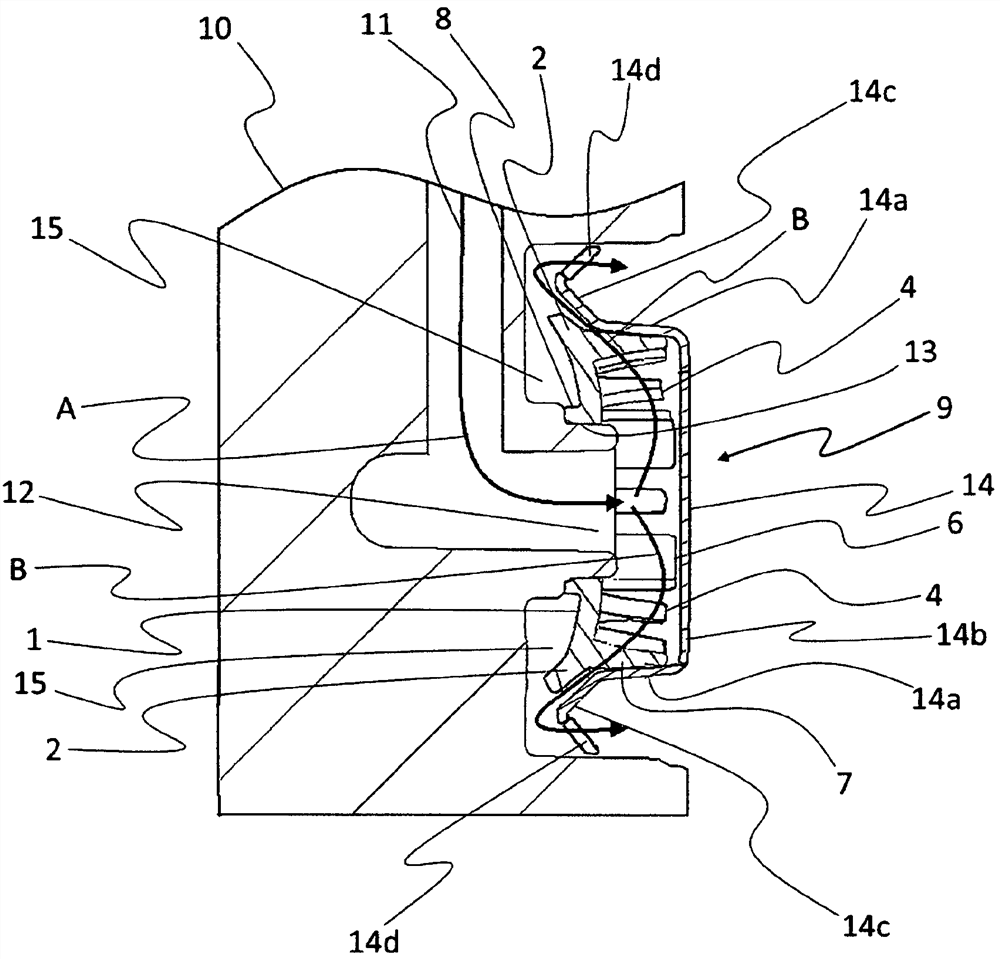

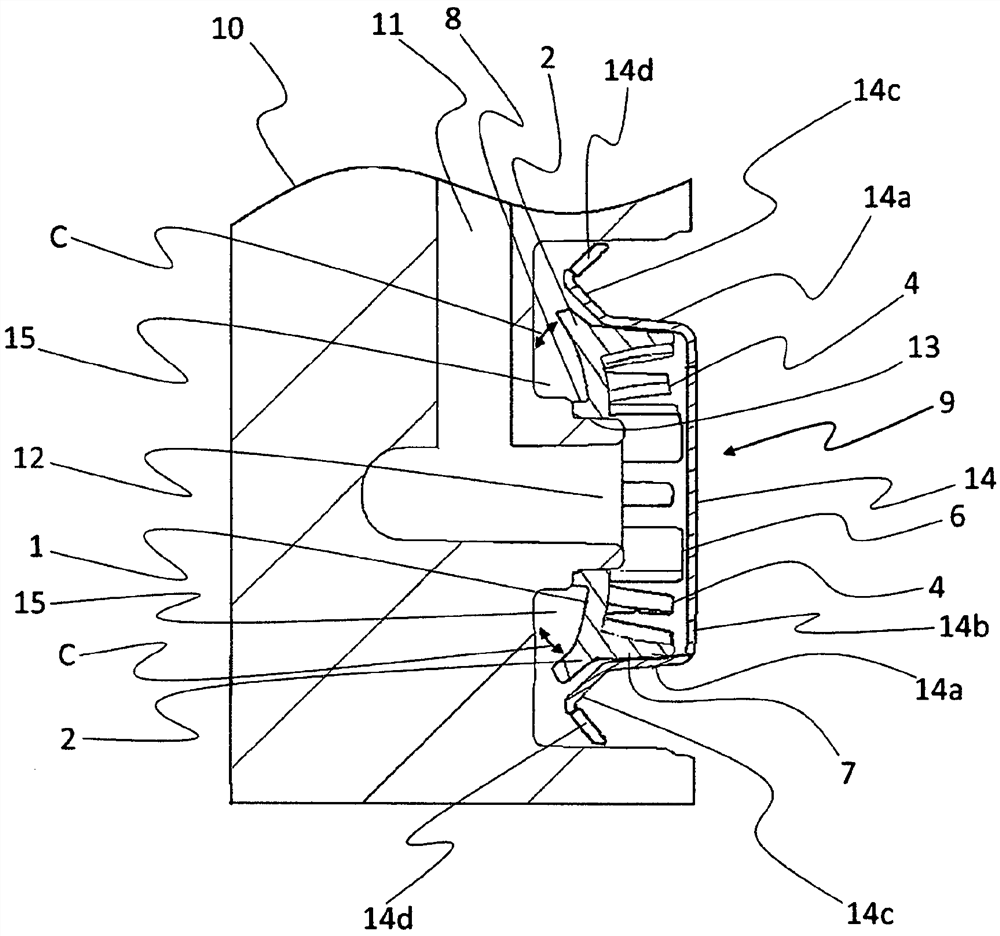

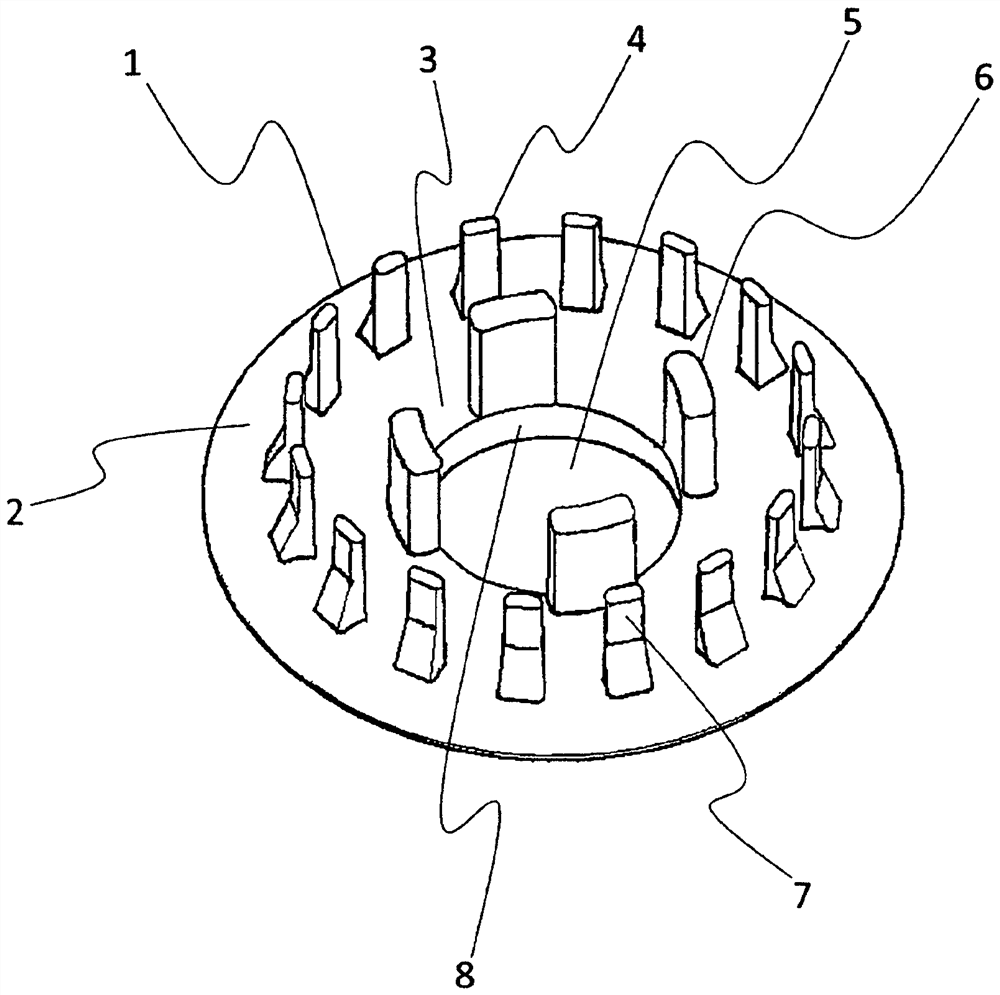

[0021] figure 1 The sealing membrane 1 is shown in a perspective view. The sealing membrane 1 is formed from a shape-elastic elastomer and has a circular base with an outer peripheral edge region 2 and an inner central region 3 . The edge region 2 forms a continuous sealing section. Directly adjacent to the surface of the sealing section formed by the edge area 2, a plurality of friction teeth are arranged in a ring, perpendicular to the bottom surface of the sealing film (and thus also perpendicular to the plane of the sealing section formed by the edge area 2), Among them in figure 1 For better clarity, the friction tooth 4 is only indicated as an example. Here, the friction teeth 4 are accordingly arranged equally spaced from the outer edge of the edge region 2 forming the sealing section and equally spaced from each other. Alternatively, the friction teeth 4 can likewise be arranged at slightly varying distances from one another in the case of correspondingly equidista...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com