Parchment paper cigarette packing box and manufacturing method thereof

A technology of sulfuric acid paper and packaging boxes, which is applied in packaging, wrapping paper, and cigarette packaging, etc. It can solve the problems of double sheets and multiple sheets, high printing costs, and difficult separation of papers, and achieves moderate transparency and is not easy to run smoothly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

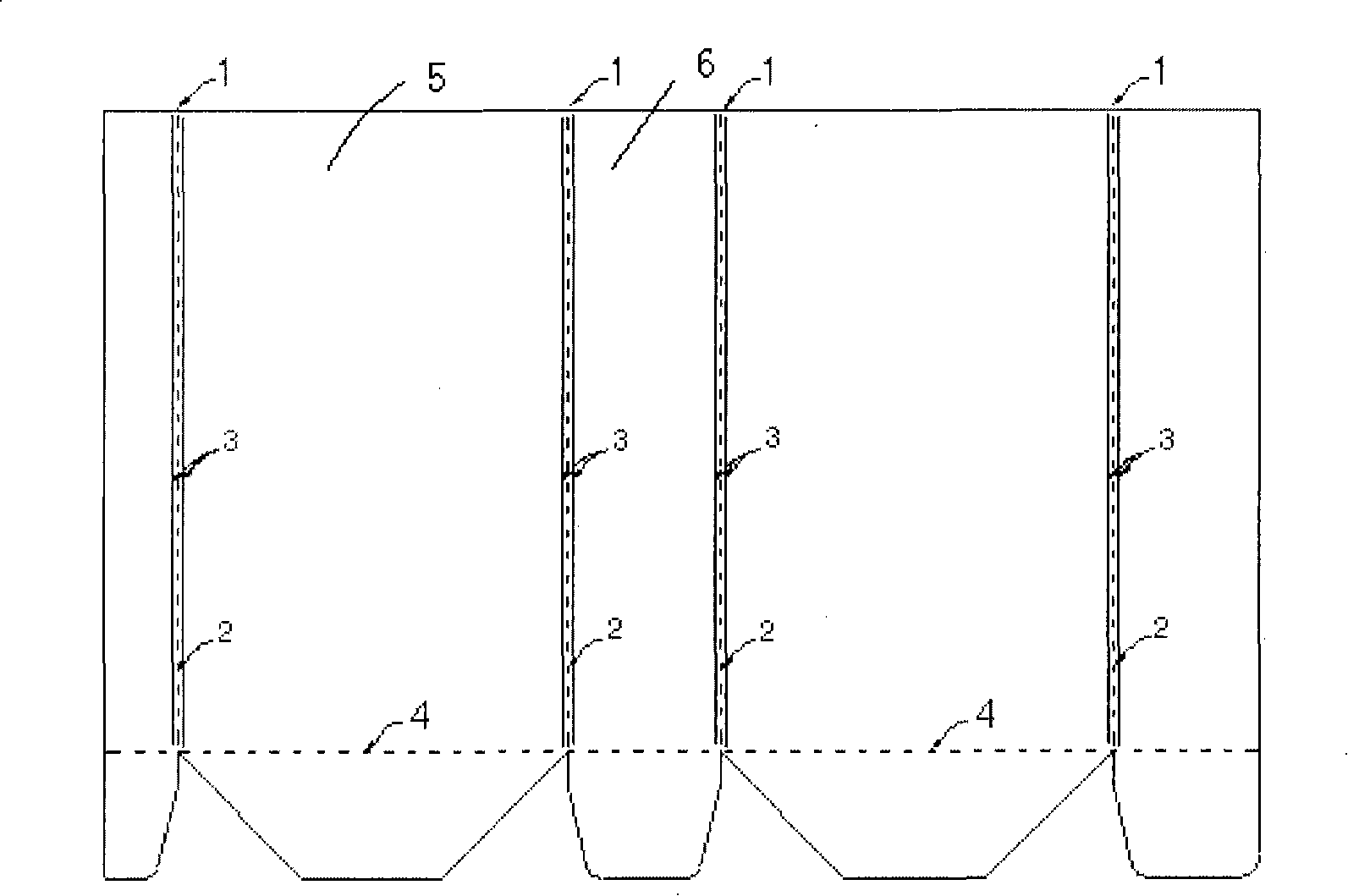

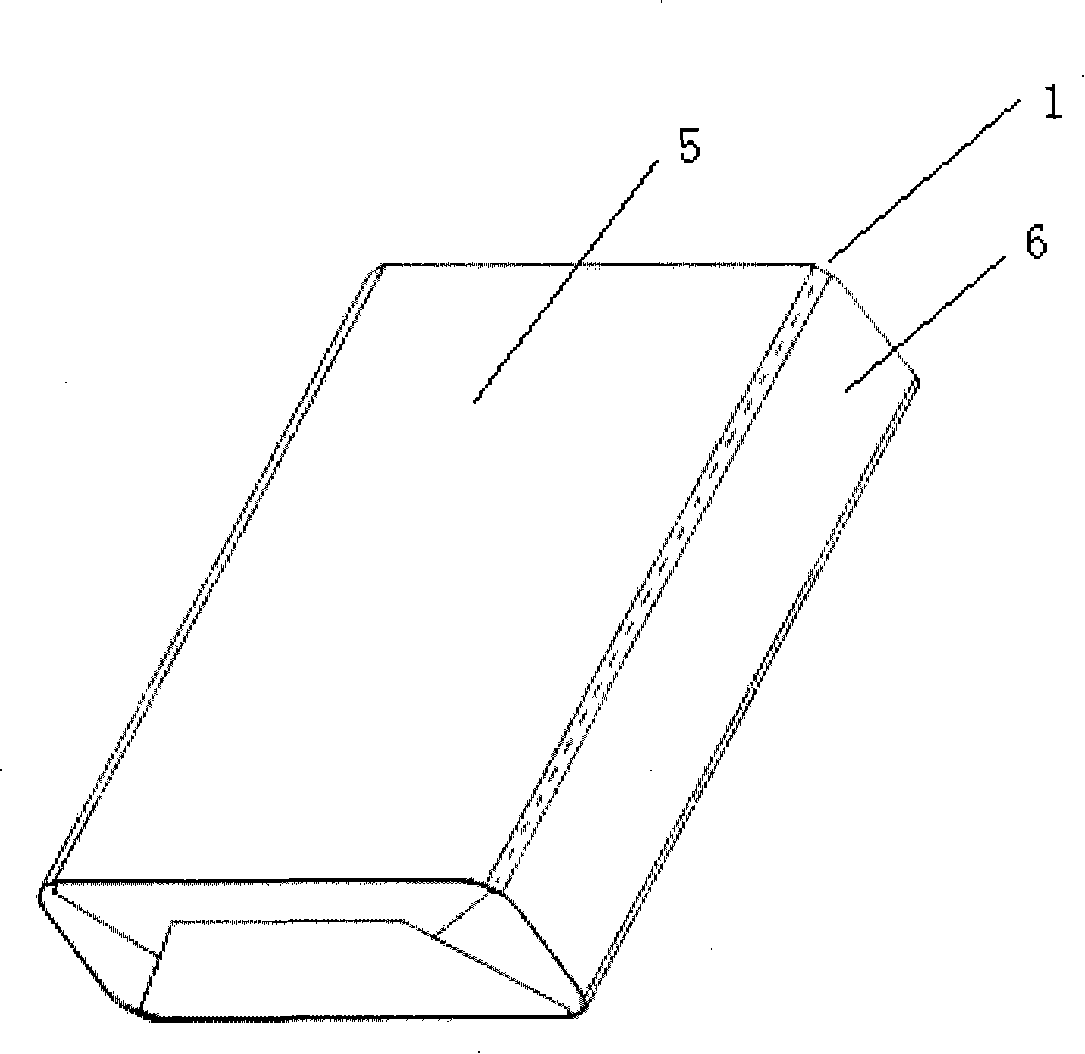

[0043] like figure 1 As shown, a sulfuric acid paper cigarette packing box includes two wide side walls 5 parallel to each other, two narrow side walls 6 parallel to each other and a lower end surface, and the wide side walls 5 and the narrow side walls 6 and the lower end surfaces are all connected to each other. Vertical; the paper used in the packaging box is sulfuric acid paper, and barcode symbols are printed on the wide sidewall 5 or narrow sidewall 6, and the quality level of the barcode symbols reaches 2.0. The grammage of described sulfuric acid paper is 90-120g / m 2 . When the sulfuric acid paper packaging box is filled with cigarettes, the bearing capacity of the wide side wall is 170-180N at the moment of crushing, and the bearing capacity of the narrow side wall is 80-85N at the moment of crushing. There is a penetrating tangent line 2 and a half-penetrating tangent line at the transition connection between the wide side wall and the narrow side wall, and the sti...

Embodiment 2

[0049] like figure 1 As shown, a sulfuric acid paper cigarette packing box includes two wide side walls 5 parallel to each other, two narrow side walls 6 parallel to each other and a lower end surface, and the wide side walls 5 and the narrow side walls 6 and the lower end surfaces are all connected to each other. Vertical; the paper used in the packaging box is sulfuric acid paper, and the barcode symbol is printed on the wide side wall 5 or the narrow side wall 6, and the quality level of the bar code symbol reaches 3.5. The grammage of described sulfuric acid paper is 120-180g / m 2 . When the sulfuric acid paper packaging box is filled with cigarettes, the bearing capacity of the wide side wall is 185-192N at the moment of crushing, and the bearing capacity of the narrow side wall is 80-85N at the moment of crushing. There is a penetrating tangent line 2 and a half-penetrating tangent line at the transition connection between the wide side wall and the narrow side wall, an...

Embodiment 3

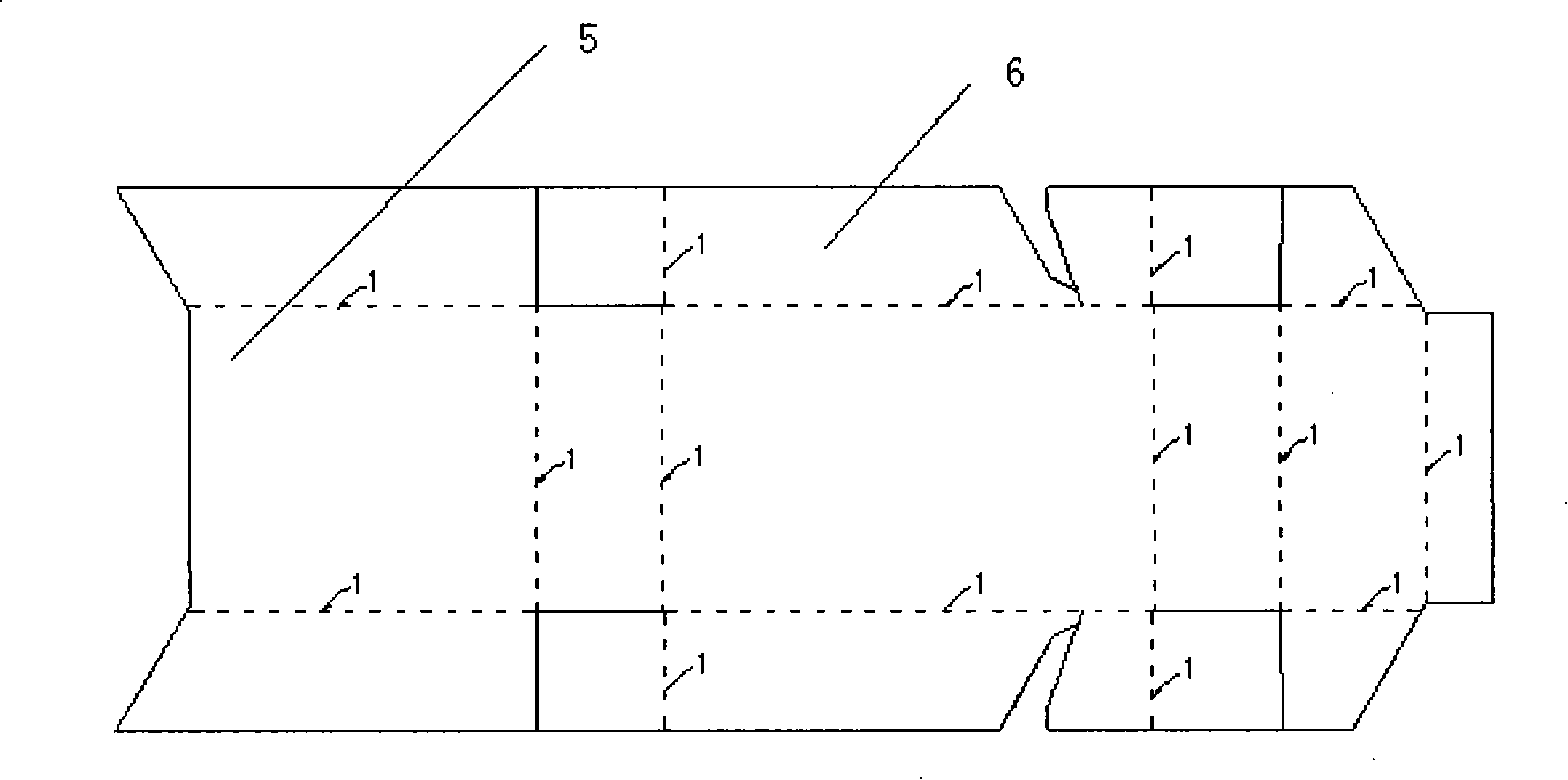

[0055] like image 3 As shown, a sulfuric acid paper cigarette packing box includes two wide side walls 5 parallel to each other, two narrow side walls 6 parallel to each other and a lower end surface, and the wide side walls 5 and the narrow side walls 6 and the lower end surfaces are all connected to each other. Vertical; the paper used in the packaging box is sulfuric acid paper, and the barcode symbol is printed on the wide side wall 5 or the narrow side wall 6, and the quality level of the bar code symbol reaches 4.5. The grammage of described sulfuric acid paper is 180-250g / m 2 . When the sulfuric acid paper packaging box is filled with cigarettes, its wide side wall 5 can withstand a force of 192-200N at the moment of crushing, and its narrow side wall 6 can withstand a force of 85-95N at the moment of crushing. At the transition connection between the wide sidewall 5 and the narrow sidewall 6, there is a crease line 1 formed by a point piercing tangent line 2, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com