Metal mixer tilting system and control method thereof

A control method and technology of a mixed iron furnace, applied in the direction of furnace control devices, furnaces, furnace components, etc., can solve the problems of inverter DC circuit overvoltage faults and excessive energy, and achieve the effect of avoiding inverter overcurrent faults and

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

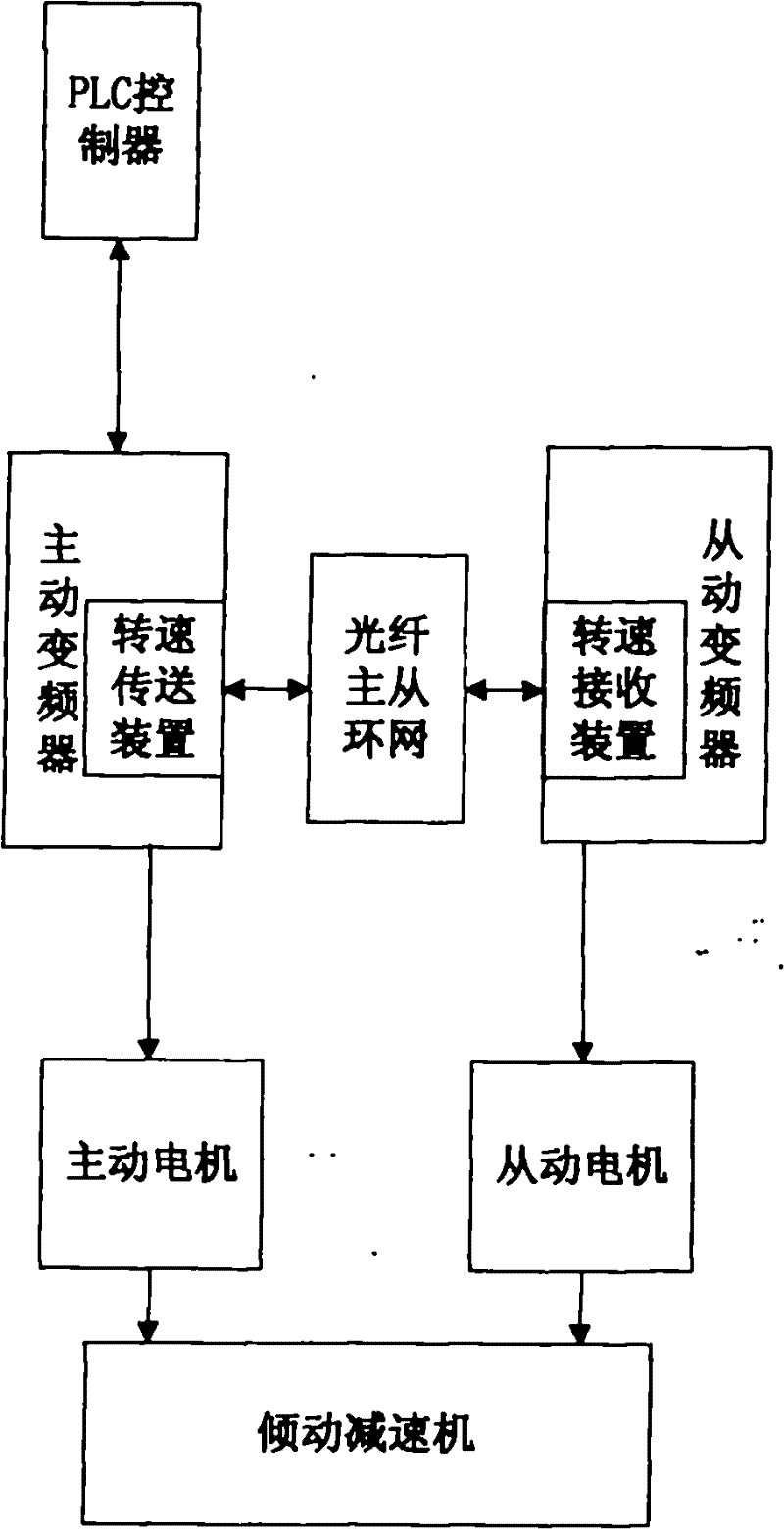

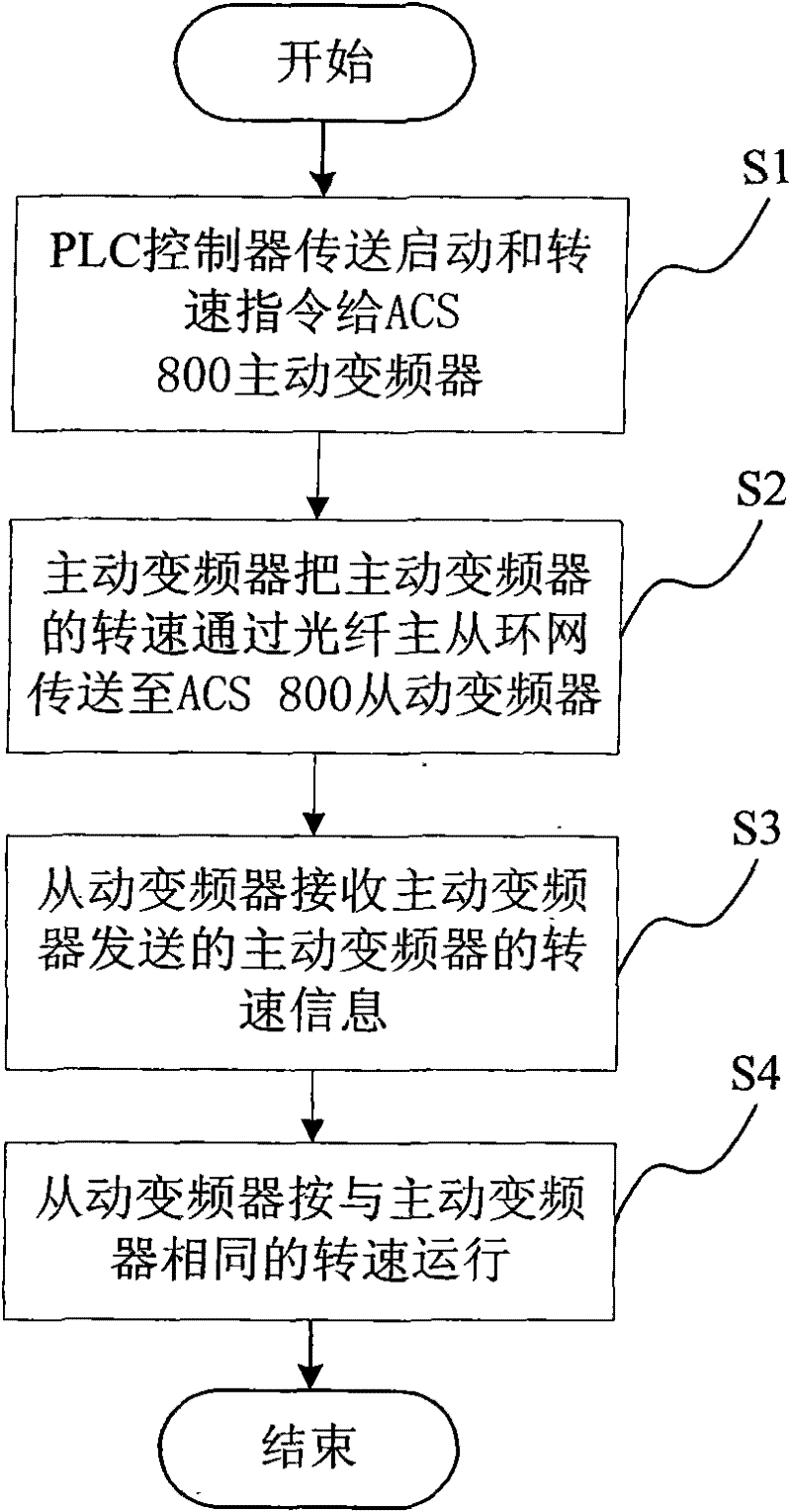

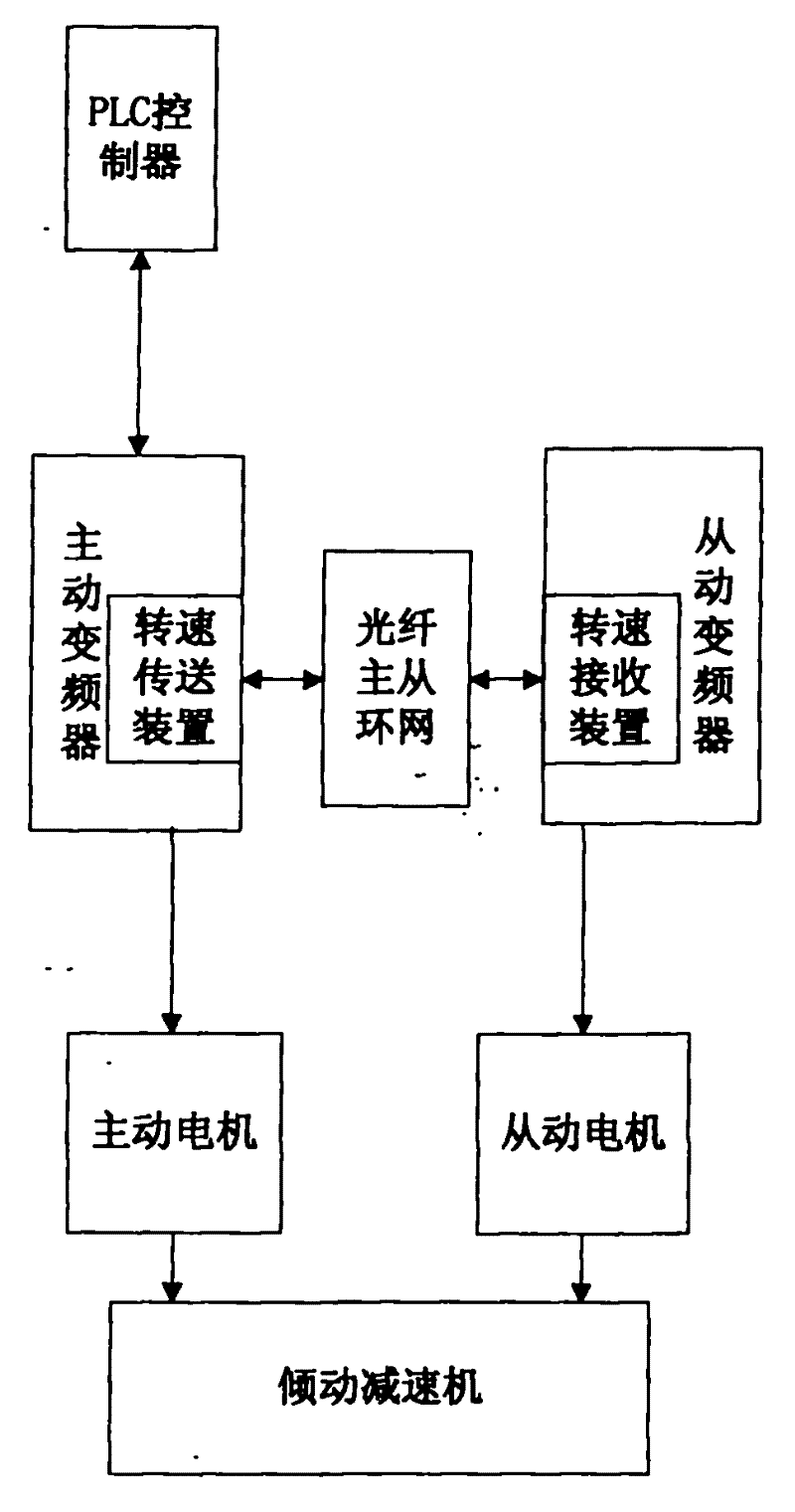

[0020] Hereinafter, the tilting system and control method of the mixing furnace of the present invention will be further described in conjunction with the accompanying drawings of the specification.

[0021] See figure 1 , The tilting system for the mixing furnace of the present invention includes a tilting reducer connected to the mixing furnace, the tilting reducer is connected to a driving motor and a driven motor, and the driving motor and the driven motor are respectively connected to the driving frequency converter and the driven frequency converter The models of the active frequency converter and the driven frequency converter are both ACS 800, and the above-mentioned connection relationship is the same as that of the prior art. The difference between the mixing furnace tilting system of the present invention and the prior art is:

[0022] It also includes a PLC controller for transmitting start and speed commands to the active frequency converter;

[0023] The active frequen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com