Anti-overcurrent device

An overcurrent and circuit technology, applied in circuit devices, emergency protection circuit devices, and protection that responds to overcurrents, etc., can solve problems such as unreasonable circuits, frequent startup and shutdown of power equipment, and limited funds, saving time. Cost and labor cost, avoid frequent fuse replacement, and solve the effect of overcurrent fault

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

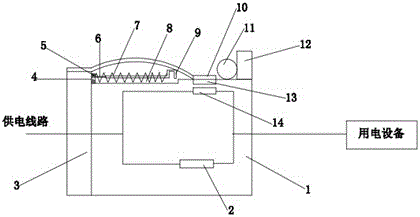

[0025] to combine figure 1 , an anti-overcurrent device, characterized in that: it includes a main body (1), and an anti-overcurrent circuit is arranged inside the main body (1), and the anti-overcurrent circuit is connected to the power supply line of the electrical equipment, and the The anti-overcurrent circuit includes a first resettable fuse (2) and a first piezoresistor (14) connected in parallel; a first contact sheet (13) is arranged on the surface of the first piezoresistor (14). An auxiliary limit mechanism is welded on the first contact piece (13), and the auxiliary limit mechanism is used to cut off the control circuit of the electrical equipment. The left side of the main body (1) is fixed with a first fixed body (3), the upper end surface of the main body (1) is provided with a groove (8), the first fixed body (3) and the groove ( 8) A first vertical part (5) is fixed above the joint, a first through hole (4) is set in the middle of the vertical part, and a firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com