Step-type spring supporting vehicle axle load measurement device

A measuring device and a stepped technology, applied in the field of automobile axle load weighing device, can solve the problems of increasing equipment investment cost, not having overload protection function, unable to adapt to the requirements of a large variation range of motor vehicle axle load, etc., and achieving low manufacturing cost. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The purpose and effects of the present invention will become more apparent by referring to the accompanying drawings in detail of the present invention.

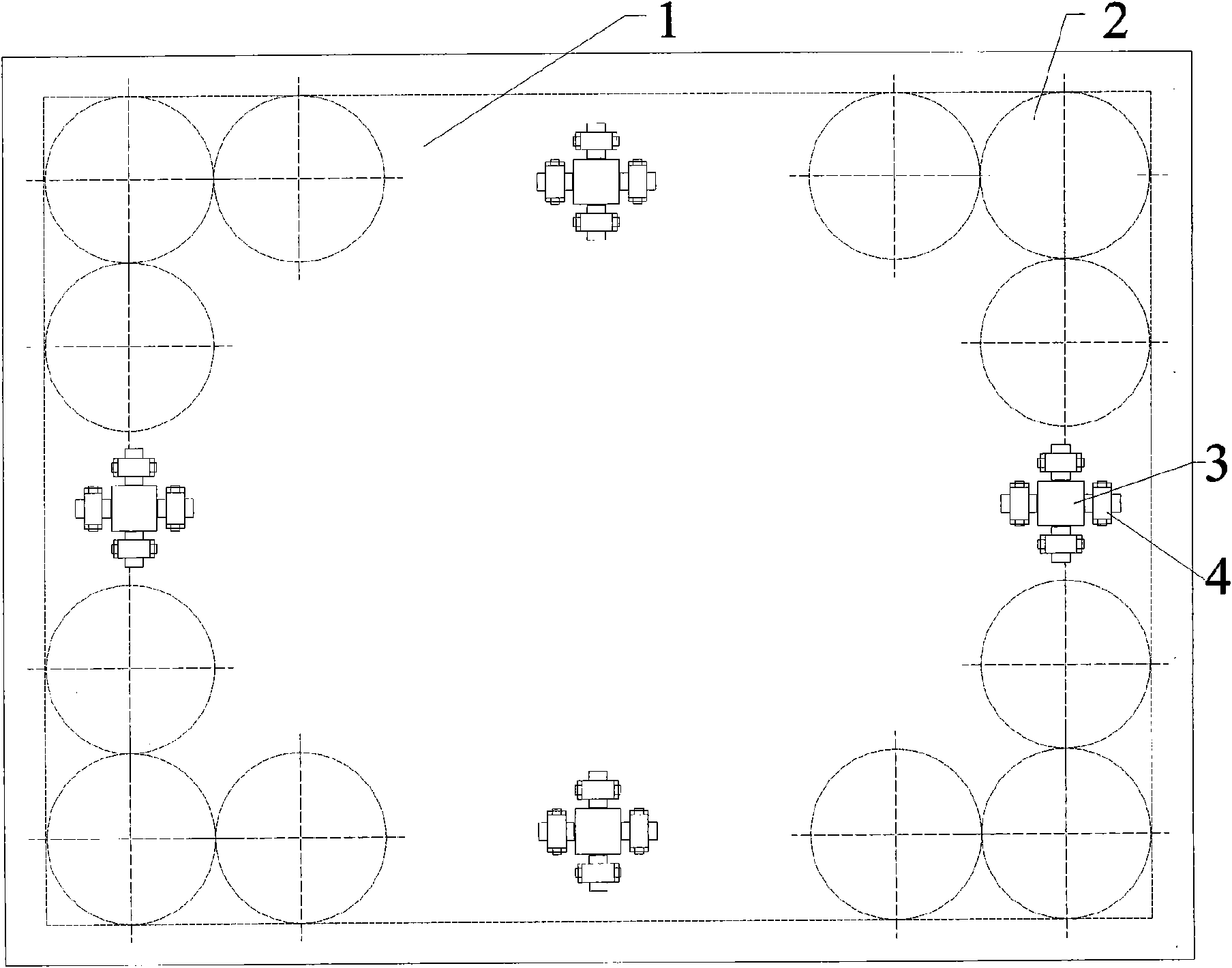

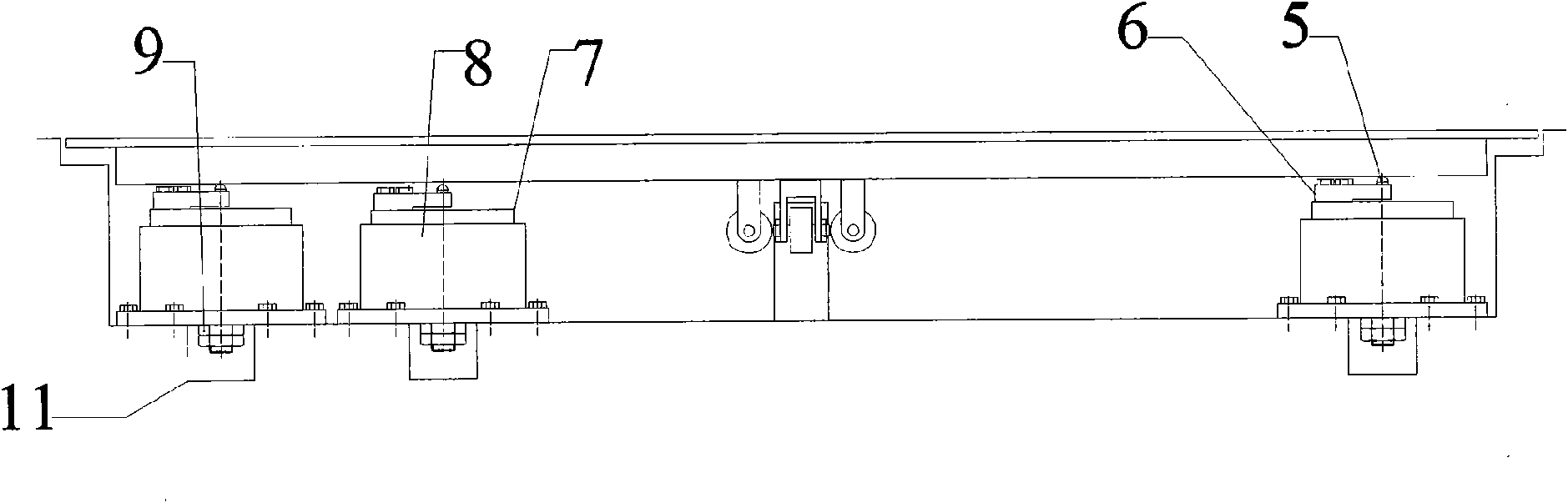

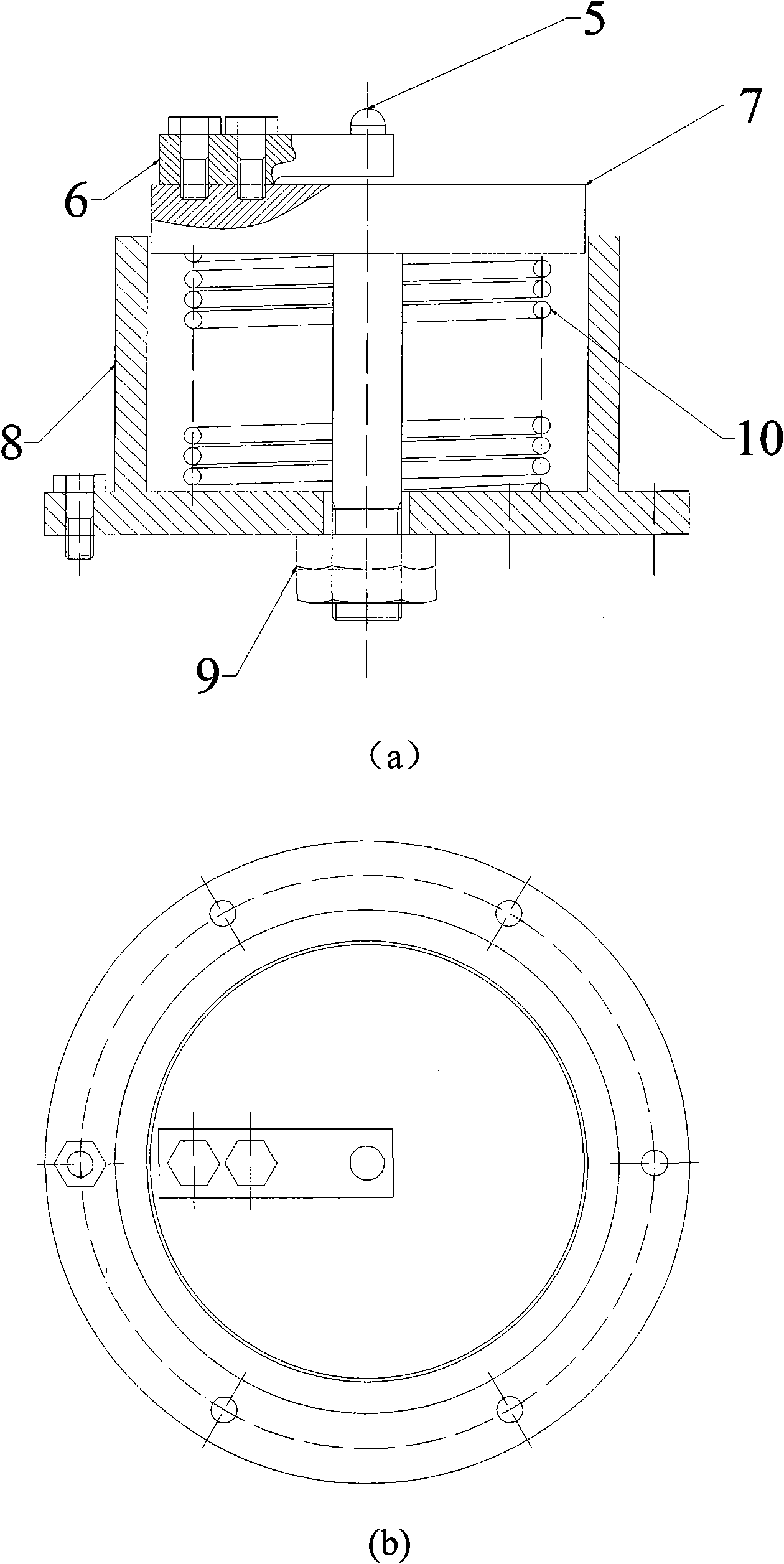

[0015] Such as figure 1 and figure 2 As shown, the vehicle axle load measuring device with stepped spring support of the present invention includes: an axle load weighing plate 1 , a spring weighing platform 2 , a metal guide column 3 , and a guide frame 4 . There are 4N spring weighing platforms 2, and N is a natural number, which is symmetrical and arranged in four corners of the pit in a stepped manner ( figure 1 Shown that each corner is 3 spring weighing platforms 2, the embodiment of 12 spring weighing platforms 2 altogether in the whole device, but the present invention is not limited thereto, each corner can be any number of spring weighing platforms 2, And the outside is high and the inside is low in a stepped arrangement), when the device of the present invention is in a no-load state, there is only one s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com