Oil well stage-cementing metal plate

A technology for steel plates and production wells, used in wellbore/well components, sealing/isolation, earth-moving drilling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Method used

Image

Examples

Embodiment Construction

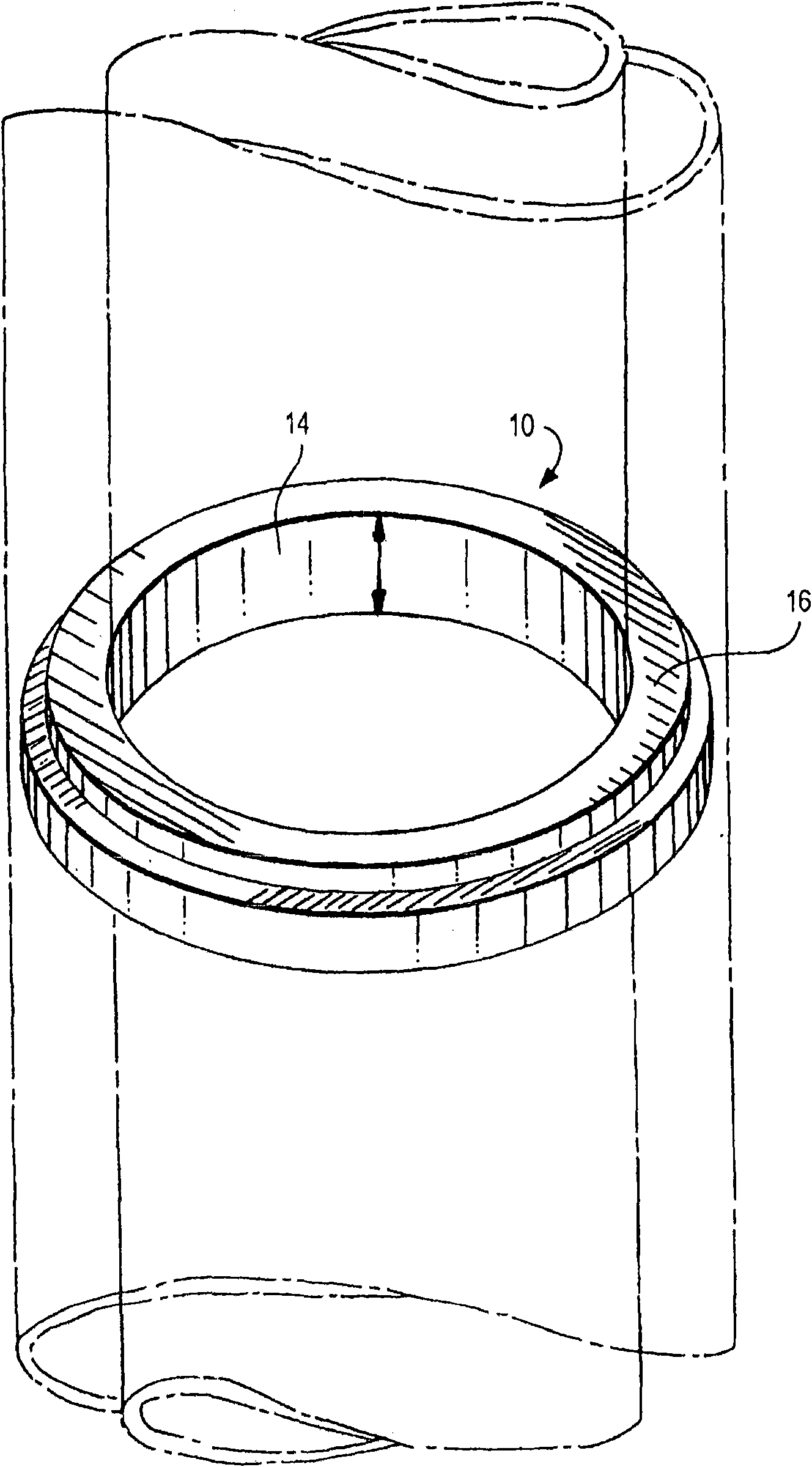

[0028] refer to figure 1 , there is shown a load bearing annulus used in the method of the present invention in place of a segmented cement grouting tool or cement umbrella in an oil well cementing operation to maintain the cement slurry above the loss of circulation zone and between two concentric casing strings steel plate. The plate 10 is annular and has a central circular opening 14 with an inner diameter slightly larger than the outer diameter of the inner sleeve and an outer diameter equal to the offset diameter of the outer sleeve. Preferably the slab is approximately 2.5 inches / 6.25cm thick and is capable of supporting the weight of a column of cement up to 4000ft / 1300m. also in figure 1 In the embodiment shown, the plate is provided with a raised shoulder 16 surrounding the central opening 14 .

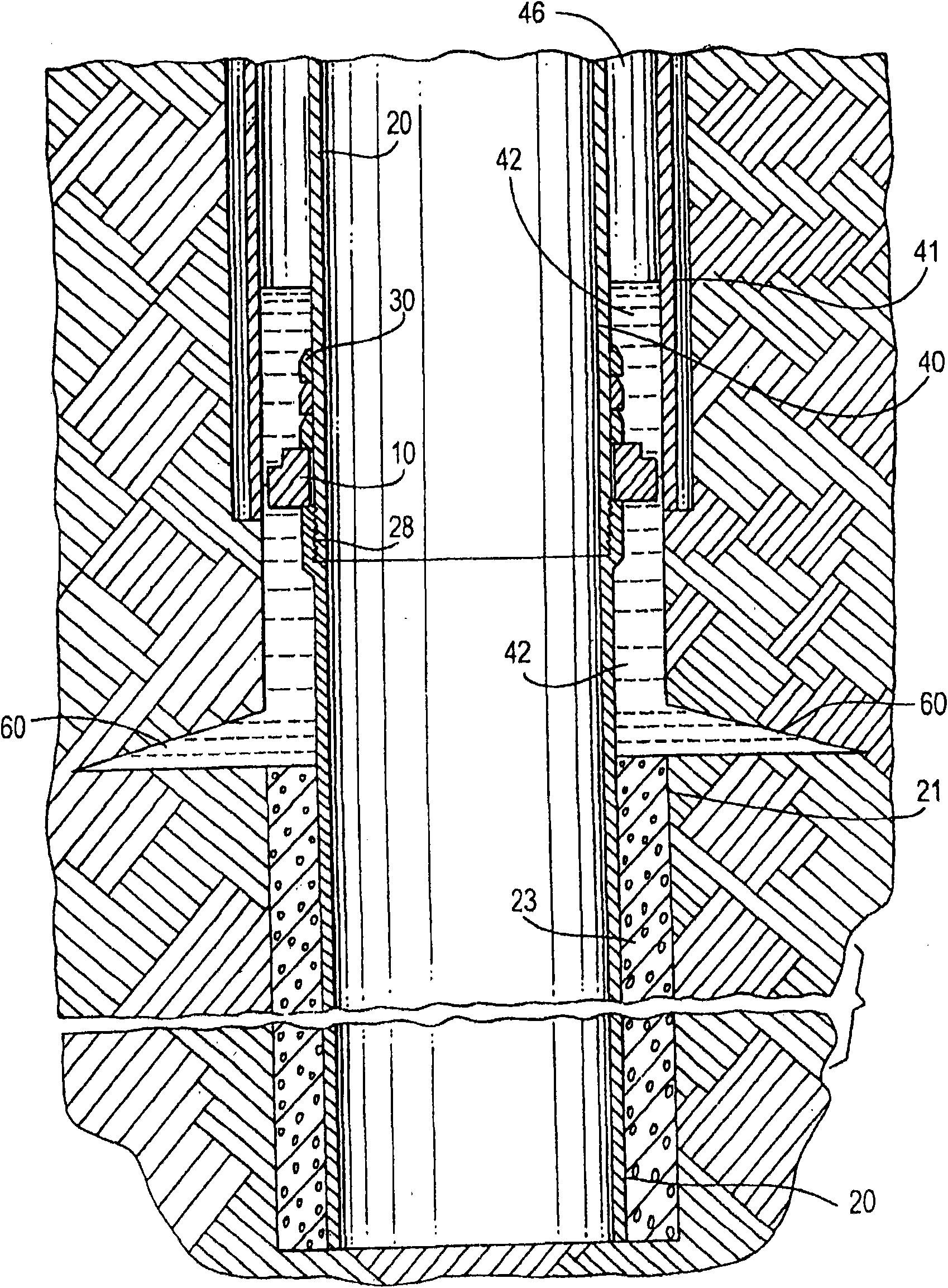

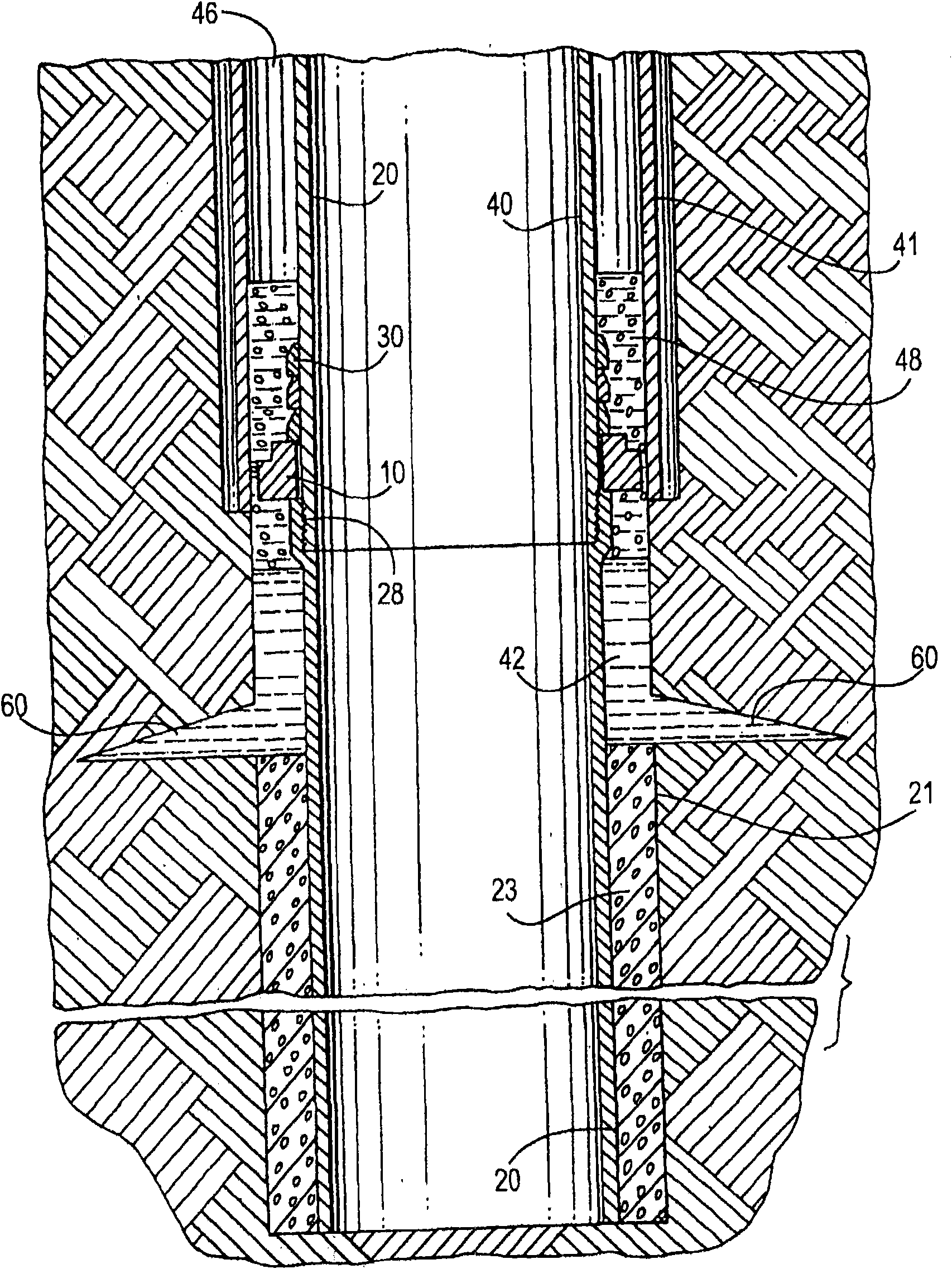

[0029] now refer to figure 2 , will illustrate the step-by-step procedure for placing cement slurry into the annulus between two casing strings, above the loss of circul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com