Rotary type multi-station lifting ultrasonic washer

An ultrasonic and cleaning machine technology, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of complex structure, large floor space, low work efficiency, etc., and achieve high cleaning quality, The effect of small footprint and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

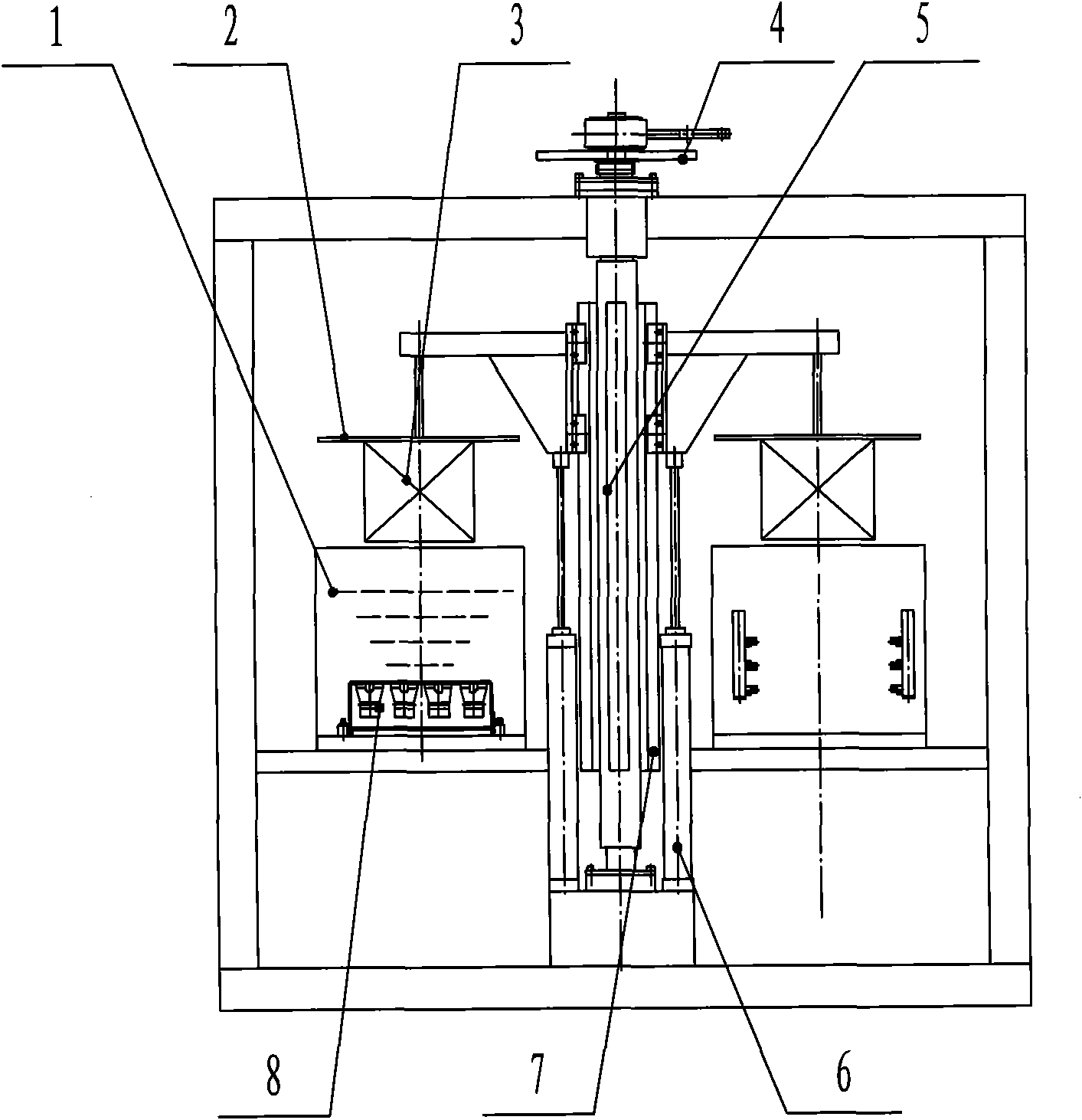

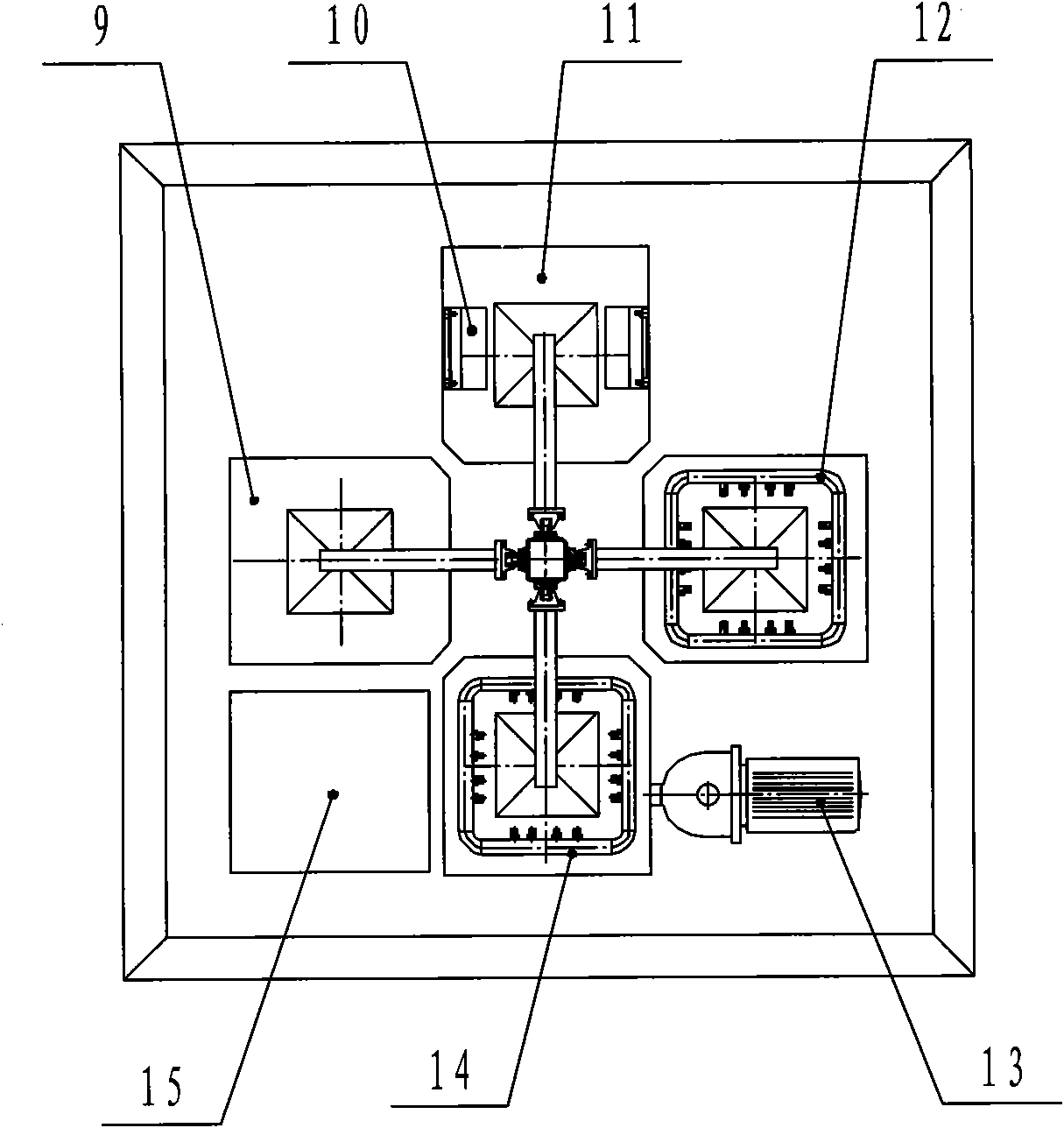

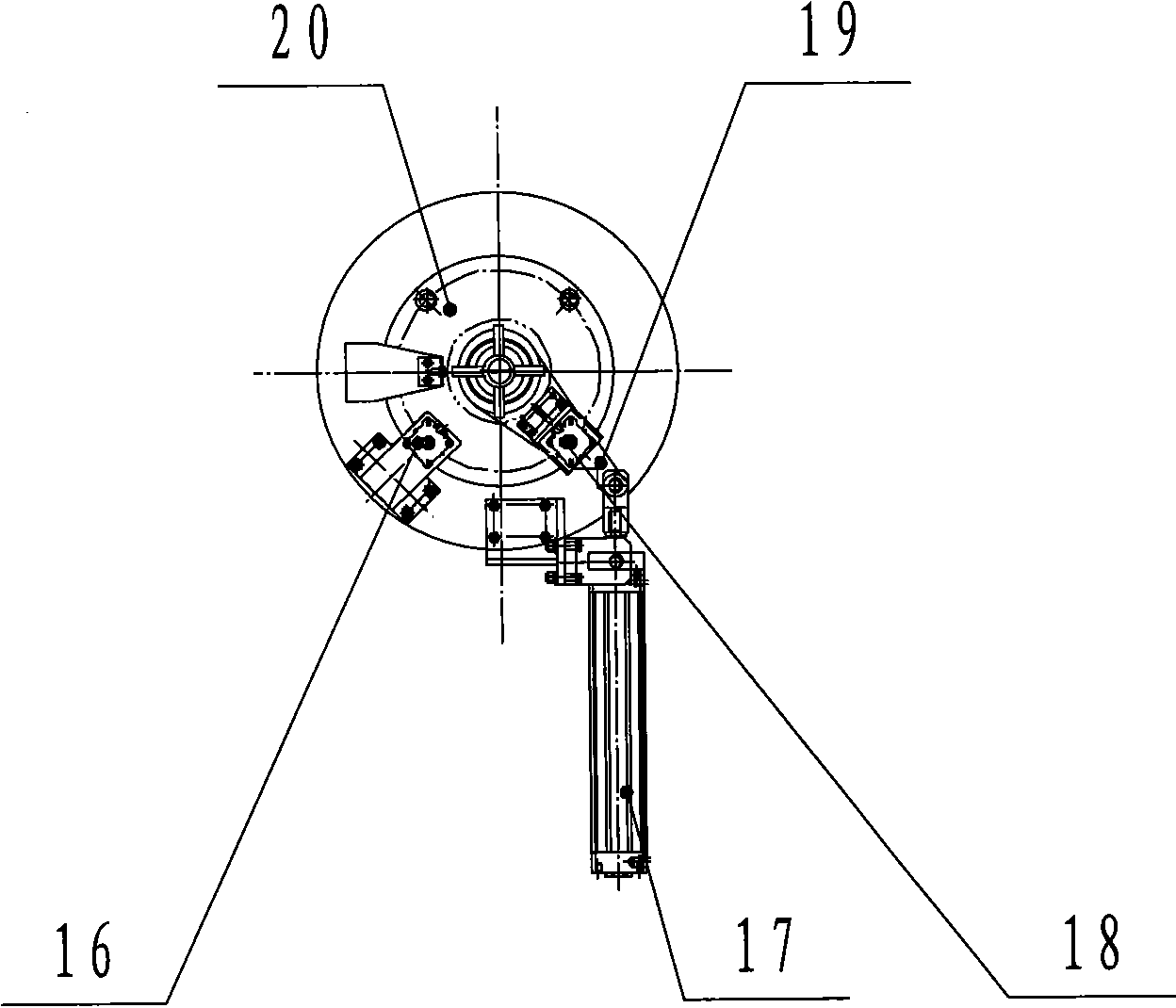

[0015] like figure 1 , figure 2 and image 3 As shown, the present invention includes a water pump 13 and a liquid storage tank body 15. It is characterized in that: a plurality of working tank bodies 1 are arranged in the washing machine, and a lifting and rotating mechanism of a workpiece hanging basket is provided at the central position of the working tank body 1, and the workpiece hanging basket 3. Connect with the lifting and rotating mechanism of the workpiece hanging basket. The workpiece hanging basket lifting and rotating mechanism is composed of the working hanging basket lifting mechanism 5 and the workpiece hanging basket rotating mechanism 4 on the cleaning machine top. There are four working tanks 1, which are respectively an ultrasonic cleaning tank 9 equipped with an ultrasonic generator 8, a spray cleaning tank 14, a drying tank 12 and a drying tank 11 equipped with a drying device. . The workpiece hanging basket lifting mechanism 5 includes a driving cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com