Exit collector of smoothing electrodesalting and electrodehydrating device

A dehydration equipment and advective technology, applied in the direction of electricity/magnetic dehydration/demulsification, etc., can solve the problems of complex tank structure, high salt water content, inconvenient maintenance of oil collecting room, etc. The effect of uniform flow rate and easy discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

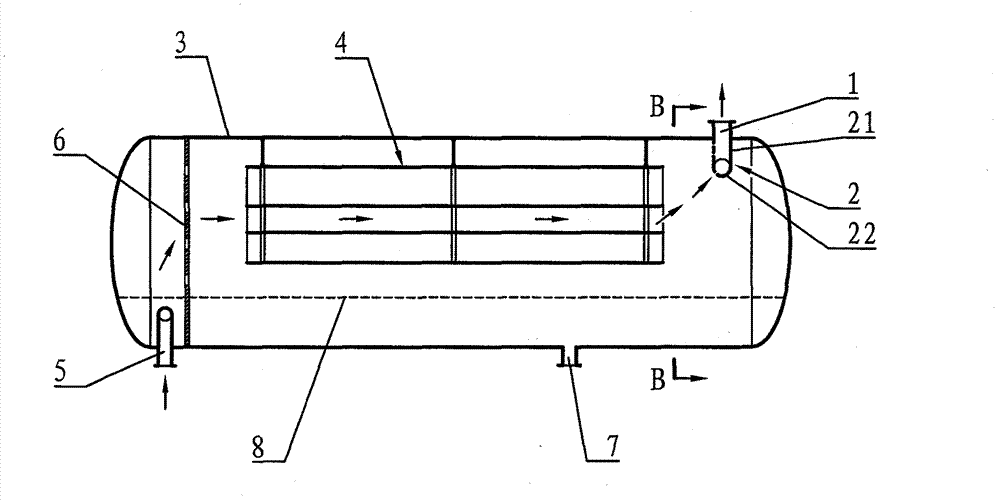

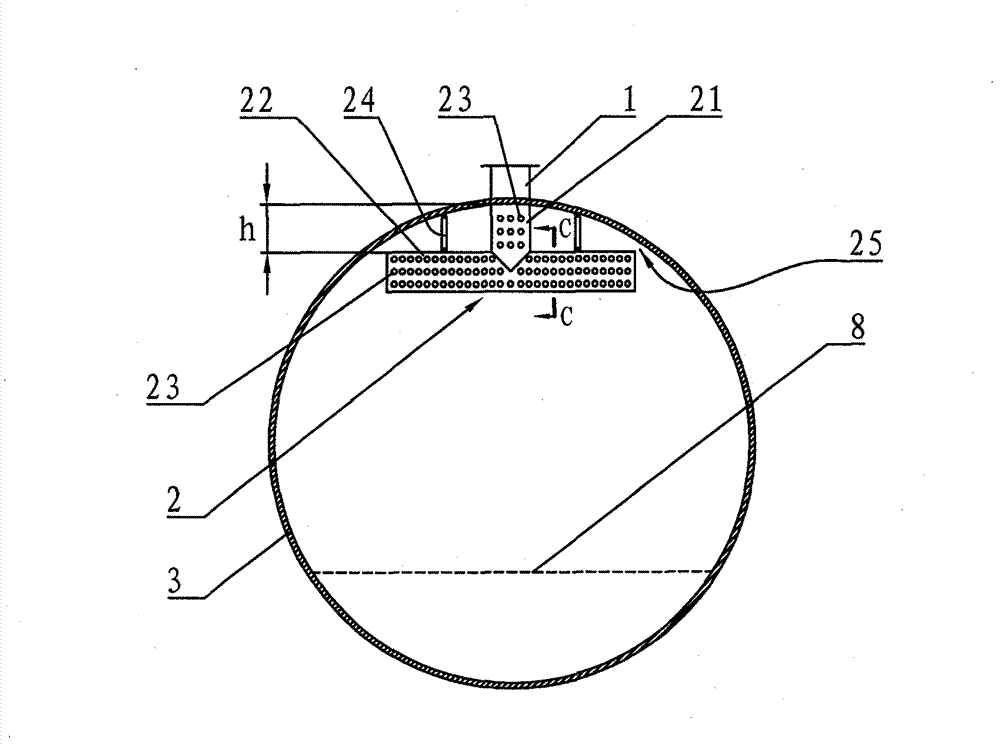

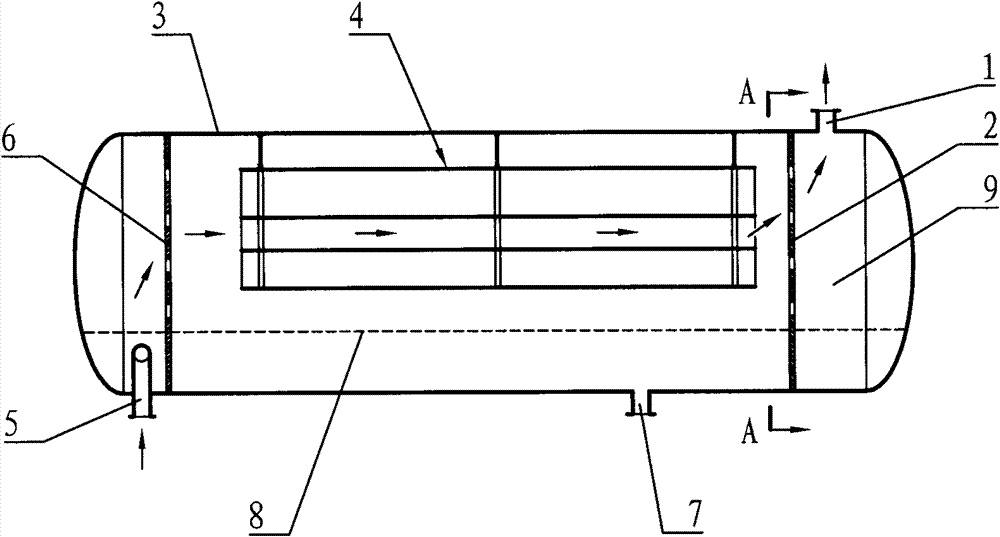

[0030] Adopt the advection electric desalination and dehydration equipment described in the comparative example, only the outlet collector of the perforated baffle plate type is replaced by the outlet collector 2 of the present invention, see image 3 and Figure 4 . Both the vertical pipe 21 and the horizontal pipe 22 have a diameter of 325 mm and a wall thickness of 12 mm. The distance h between the top of the cylindrical surface of the horizontal tube 22 and the top of the inner wall of the tank body 3 is 300 mm. The perforation rate of perforation 23 on the vertical pipe 21 and the horizontal pipe 22 is 50%; There is a gap 25 between the top of the horizontal pipe 22 two ends and the inner wall of the tank body 3, and the width is 150 mm.

[0031] The electric desalination and dehydration operation was performed on the same crude oil according to the conditions described in the comparative example. The difference in the operation process is that after the electrically ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com