Construction method of six-zone digging of super cross section tunnel

A technology of super large section and construction method, applied in tunnels, tunnel linings, earthwork drilling and other directions, can solve the problems of mutual interference, many blocks, slow construction progress, etc. effect of input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

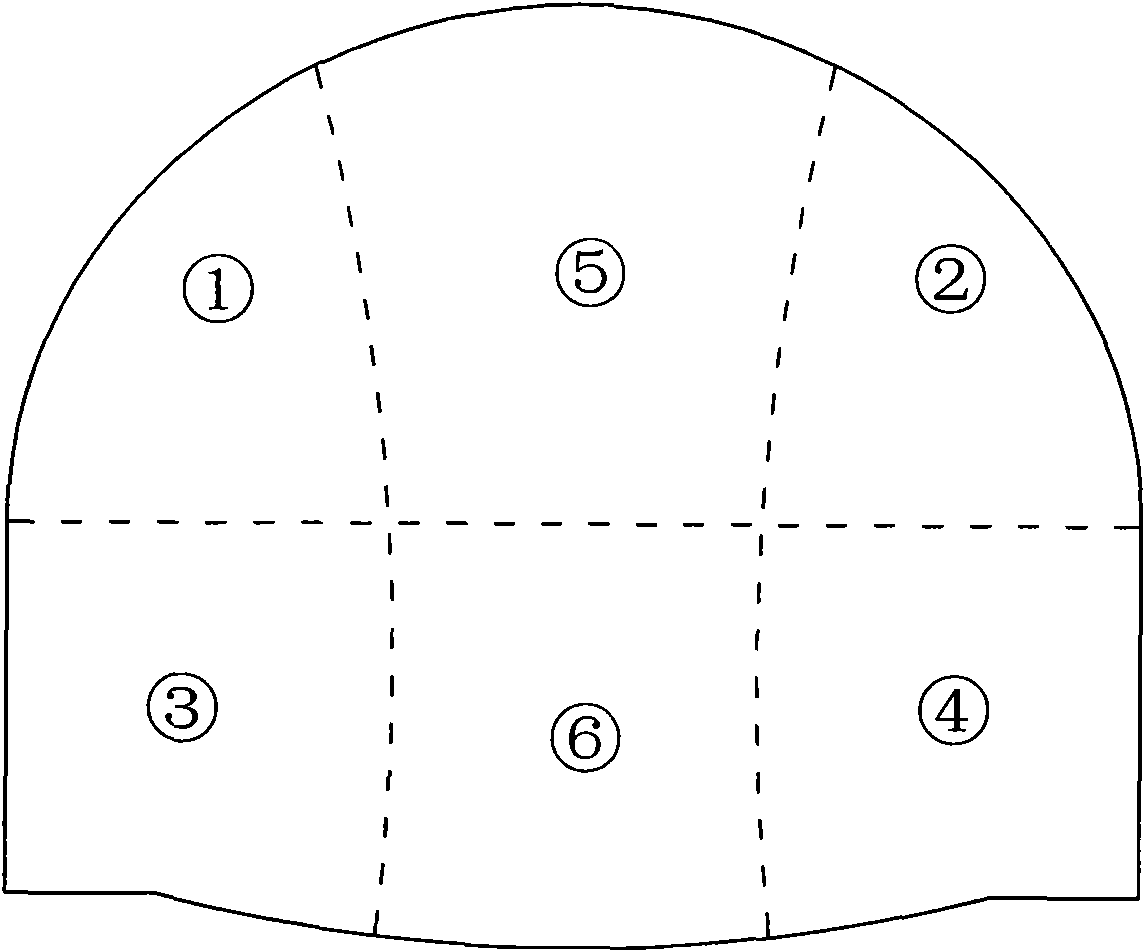

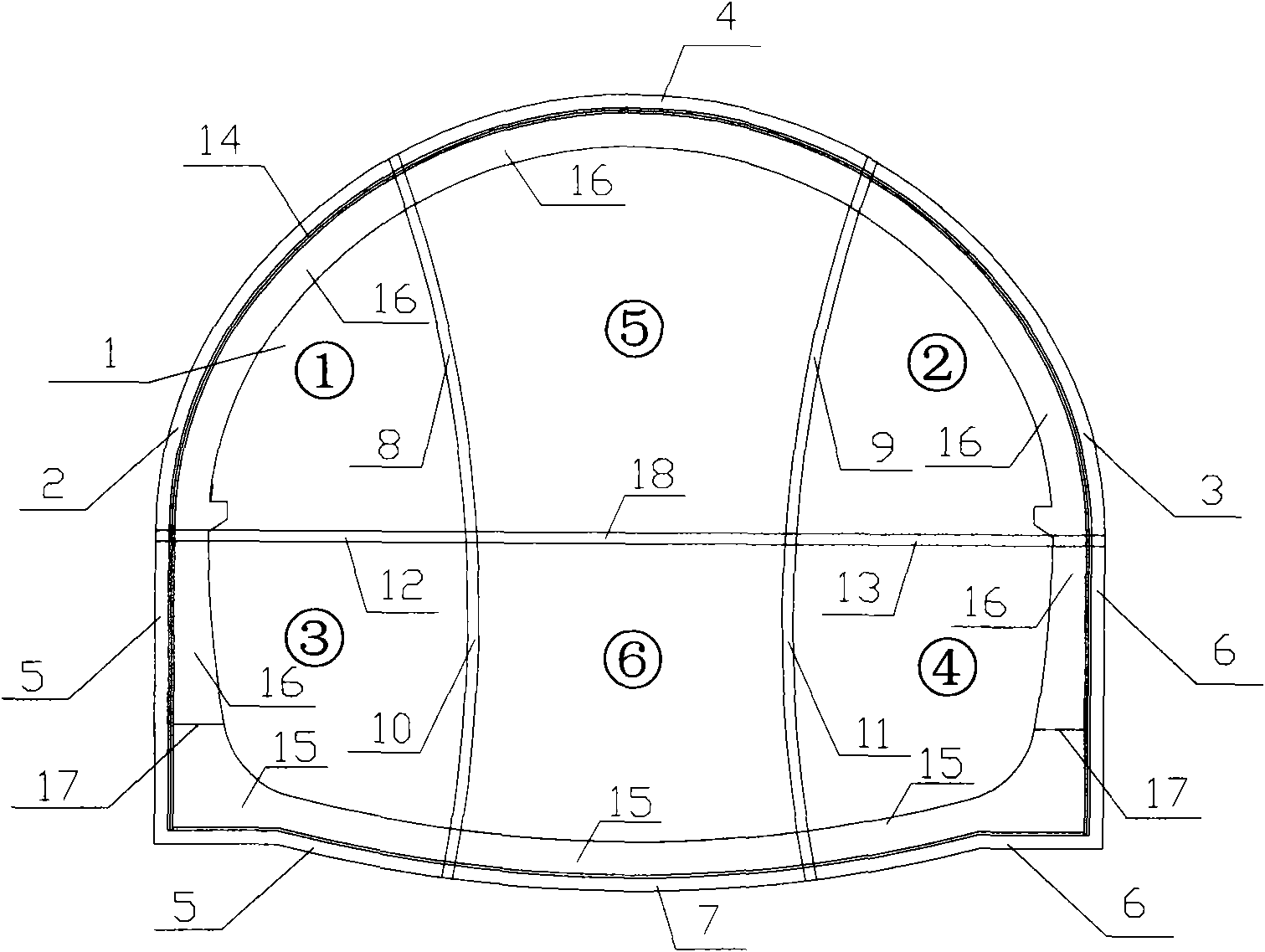

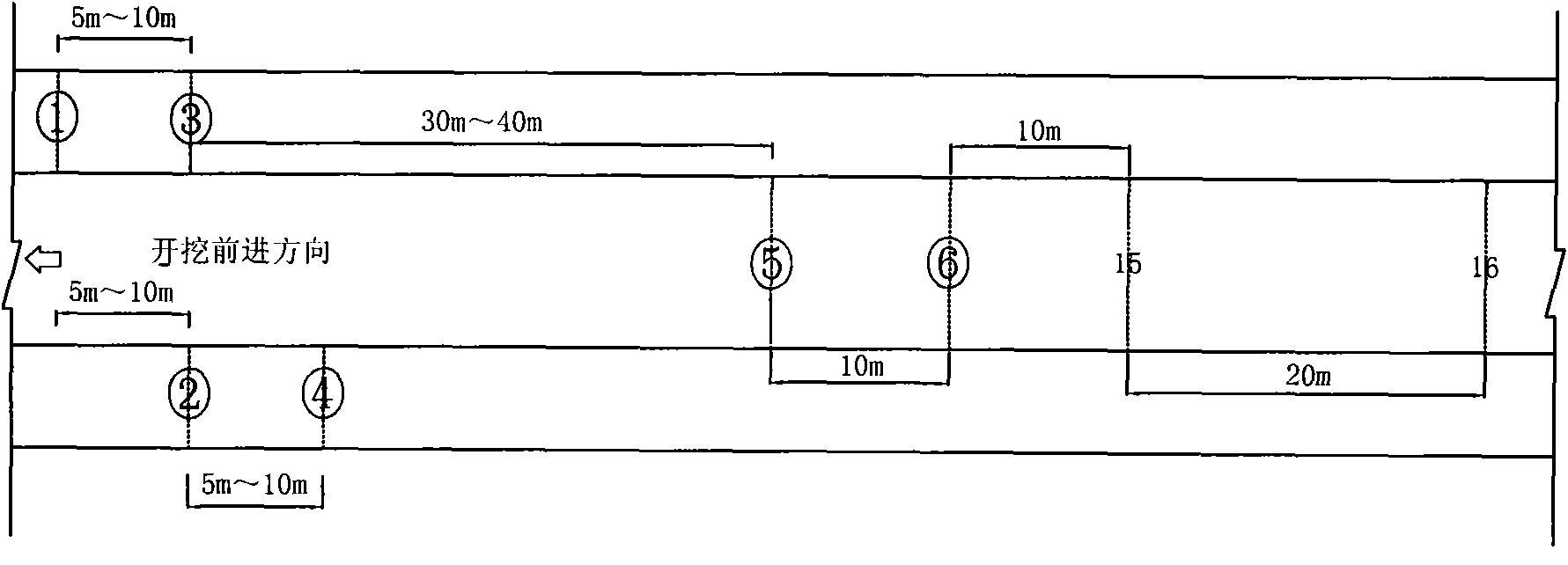

[0028] see figure 1 , in this embodiment, the section of the tunnel is divided into upper left area ①, upper right area ②, upper middle area ⑤, lower left area ③, lower right area ④, and lower middle area ⑥ on the tunnel section according to the top, bottom, left, middle, and right. , according to the division that was constructed first to form a ring first, and then form a ring together with the adjacent division when the construction of the adjacent division is completed, and finally the tunnel as a whole forms a ring, forming a construction method of early closure and early formation of the ring. The specific construction steps are as follows:

[0029] 1. Construction of Part ① and Part ②

[0030] figure 2 As shown, the tunnel is constructed separately on the left and right sides. After the smooth blasting of the ① part, the construction of the initial support 2 of the ① part and the temporary upper left intermediate wall support 8 is carried out in time to form a small-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com