Connection method of double-wall corrugated pipes

A double-wall corrugated pipe and connection method technology, which is applied in the direction of pipeline connection arrangement, pipe/pipe joint/pipe fitting, mechanical equipment, etc., can solve problems such as inability to guarantee product quality and hidden dangers of welding strength, so as to avoid hidden dangers in quality and low cost , Improve the effect of project quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

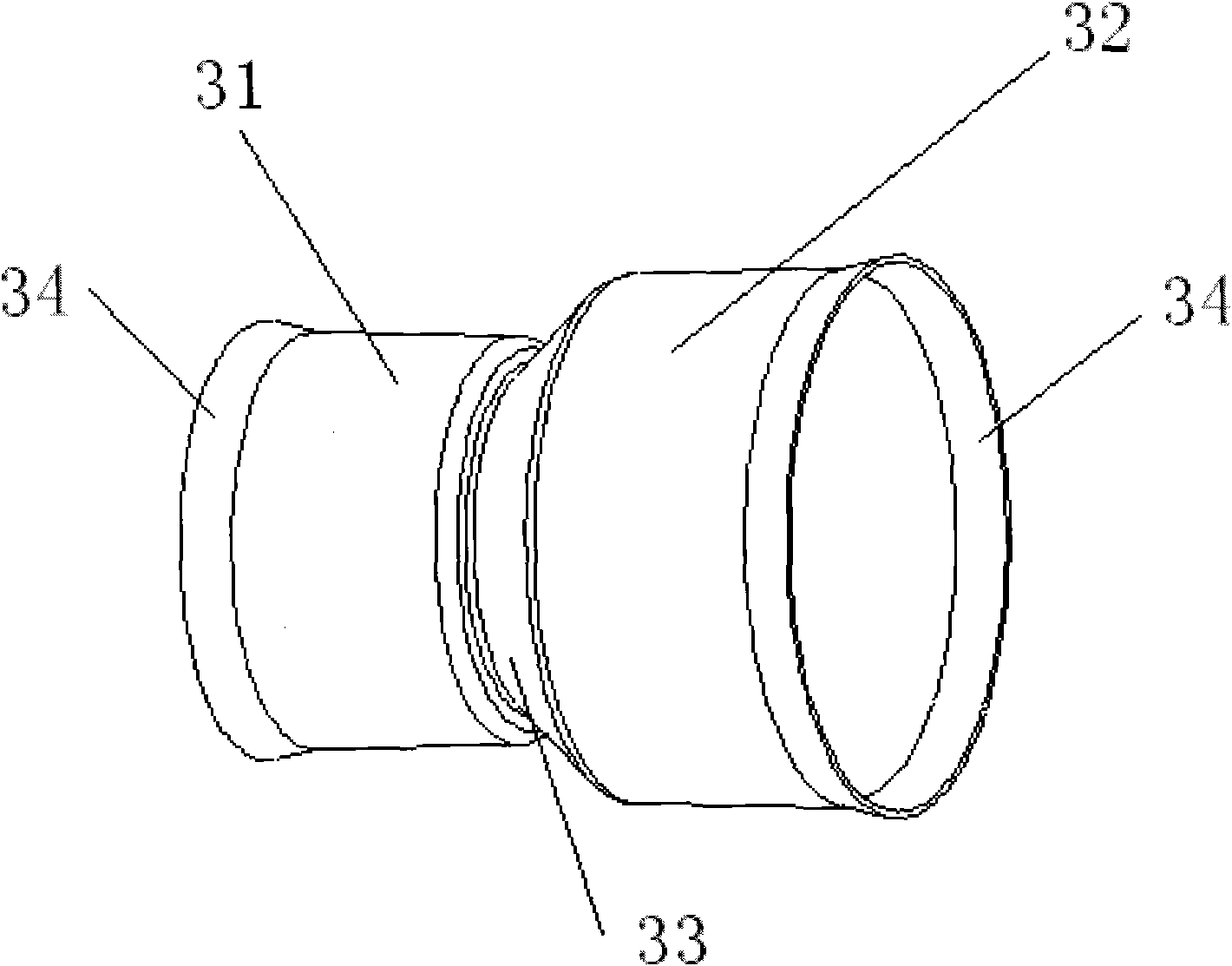

[0023] The connector structure that the present invention adopts is as attached figure 1 As shown, it includes a first straight section 31 with a smaller diameter and a second straight section 32 with a larger diameter, and a trumpet-shaped connecting section 33 is connected between the first straight section 31 and the second straight section 32 , the thickness of the connecting section 33 is greater than the thickness of the two straight sections, and the ports of the two straight sections are provided with chamfers 34 for easy installation.

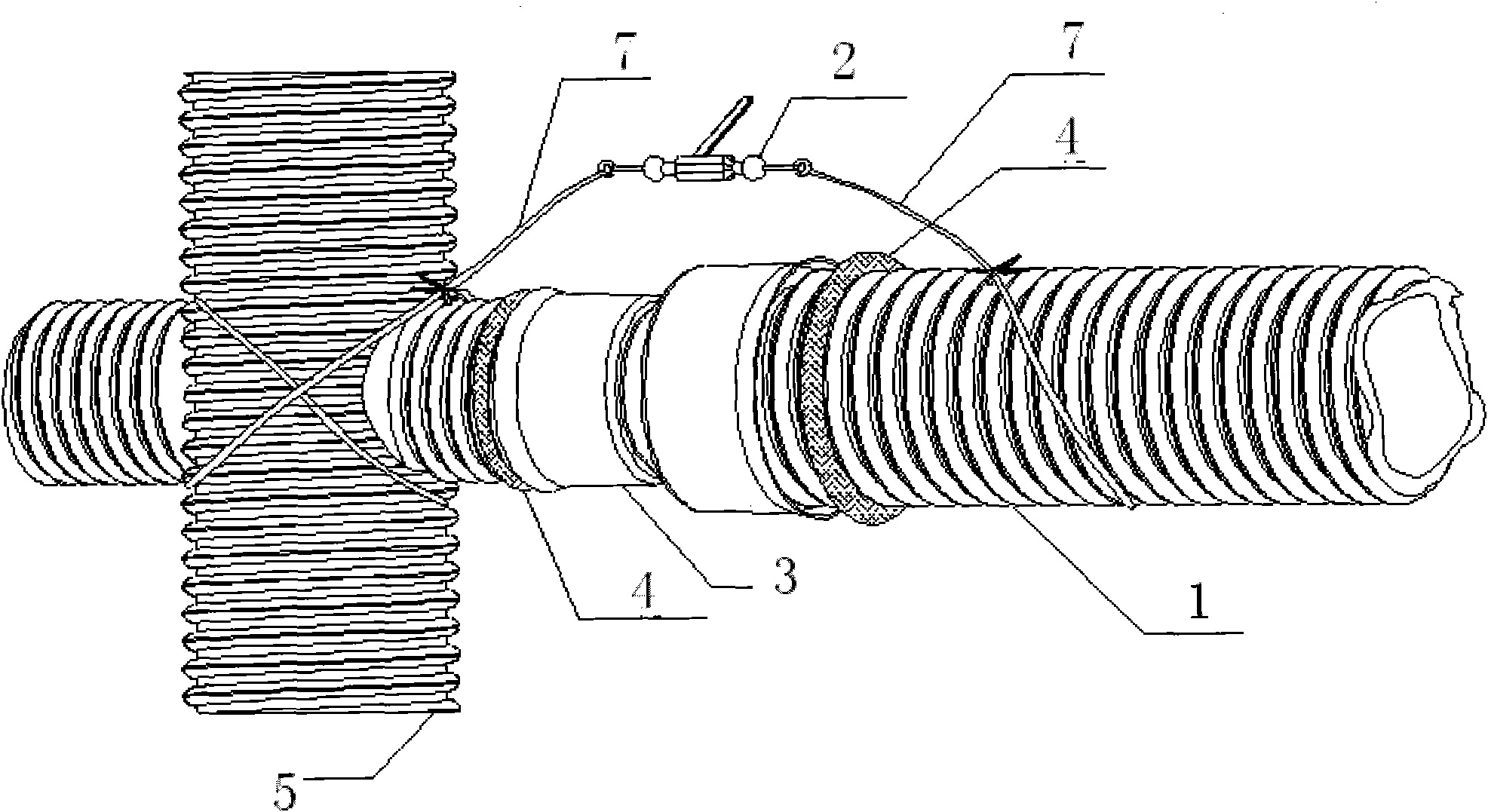

[0024] The implementation process of the present invention is as attached figure 2 As shown, first use the double-wall corrugated pipe 1 and another double-wall corrugated pipe as the connecting pipe 5 to clean the surface debris. Install the sealing ring 4 to the first peak groove of the socket of the bellows 1 and the conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com